Hey, if you’re knee-deep in waste management or just eyeing ways to turn trash like old tires and plastics into something useful, you’ve probably heard about pyrolysis. It’s that process where heat breaks down waste without oxygen, spitting out fuel oil, carbon black, and gas. But here’s the thing—not all setups are the same. Continuous pyrolysis plants? They’re often the eco-champ over batch systems. We’ll dive into why, pulling from real ops in China where this tech’s booming. Think 380 million tons of plastics made in 2018 alone, with China leading the waste pile-up. By 2030, plastics could hit 14% of municipal solid waste there. Batch systems have their spot, but continuous ones cut emissions, save energy, and crank out more goodies. Let’s break it down, with numbers from plants handling 50-100 tons a day.

First off, pyrolysis isn’t new—it’s been around for decades, turning organic junk into valuables. Heat waste to 400-600°C in a sealed reactor, no air, and it cracks into oil (for fuel), syngas (burnable gas), and carbon black (for tires, inks).

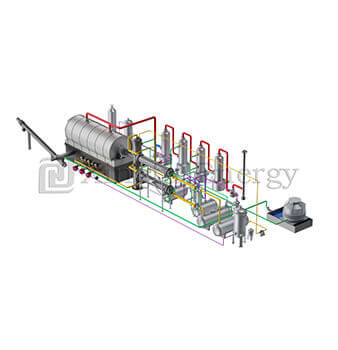

But the magic’s in how you run it. Batch systems load waste, heat, cool, unload—repeat. Downtime between cycles? Common. Continuous pyrolysis? Feeds waste non-stop, products flow out steady. No pauses.

In a Qingdao plant I know, they process mixed plastics and tires. Batch might handle 10 tons per run, but continuous hits 30 tons daily without breaks. Why care? Less waste lingers, more gets recycled fast.

Energy’s a big deal—pyrolysis guzzles heat. Continuous plants keep temps steady, no wild swings like batch setups where each cycle restarts from cool.

Take emissions. Batch systems lose heat during unload, firing up burners extra—hiking CO2. Continuous recycles syngas better, burning it to heat the reactor. One study on Chinese processes showed continuous cutting energy use 20-30%. Less fuel burned means fewer greenhouse gases.

Chinese companies continuous rig, 100 tons/day, yields 45-52% oil, 18-25% gas.

That gas? Loops back, covering 80% of heat needs.

Batch? Often wastes 10-15% more energy per ton.

And hey, ever think about the startup phase? Batch ops belch more pollutants then—dioxins if tires involved. Continuous? Smoother run, cleaner air.

Waste reduction? Continuous wins hands-down. Constant flow means even breakdown—less leftover char or uncracked bits.

For plastics: Mixed waste like PE, PP yields 43-48% oil in continuous, vs batch’s 45% but with more residue. Tires? Continuous pulls 45% oil, 40% black, 15% gas.

Batch leaves more sludge—up to 5-10% per load—from uneven heat. In oil sludge recycling, continuous handles varying feeds better, extracting 50%+ oil without clogs.

Pro: Higher yields mean less landfill dump. China’s MSW? Pyrolysis could divert 14% plastics by 2030, but only if efficient. Batch? Slower, more waste piles up waiting. Continuous often edges higher oil, lower gas waste.

Monitoring matters. Continuous plants pack advanced sensors—real-time temp, pressure, gas checks. Adjust on the fly, avoid hotspots causing emissions.

Batch? Manual loads mean risks—overheat one cycle, pollutants spike. Safety? Continuous has auto-feeds, less worker exposure to hot zones.

In a Columbia U report, they compared: Continuous runs steady, high-quality black (sellable at premium). Batch? Fluctuates, lower value products.

And downtime? Batch cools/reheats—energy suck, more wear. Continuous? 24/7, less maintenance halts.

Oh, tangent: I’ve wondered why some skip continuous—upfront cost? But payback’s 2-3 years on energy savings alone.

Let’s get concrete. In Shandong, a continuous plant processes 30 tons tires daily—cuts emissions 25% vs batch neighbor. Oil sold as fuel, black to rubber firms.

Plastics: 6.3 billion tons produced since 1950, 9% recycled. Continuous in Henan handles mixed waste, yielding 52% oil—fuels local gensets.

Oil sludge: Tricky, toxic. Continuous extracts 45% oil, residues minimal—beats batch’s 30% leftover mess.

Economics? Continuous ROI faster—China claims eco-friendly edge with low black yield (more oil cash). Global: Exported to 30 countries, Mongolia to Spain.

Challenges? Feed consistency—sort waste first. But continuous adapts better.

Shopping for pyrolysis gear? Qingdao Xingfu Energy Equipment Co.,Ltd‘s got you. Founded 2010, they’re a high-tech outfit in Shandong, cranking out industrial boilers, vessels, and waste tire/plastic pyrolysis systems—batch, semi-continuous, full continuous.

Plant spans 70,500 square meters, 228 workers: 78 techs (21%), 28 engineers, 136 skilled hands, 65 welders. R&D strong—18 seniors, 40+ machines. Sales hit 100 million RMB since 2012. Certs: CE, ISO9001, pressure vessel licenses.

Products: 8-16 ton semi-continuous, 10-20 ton batch, 15-30 ton continuous. Exported 30+ countries—Indonesia, Korea, Poland. Rep for quality, custom fits. If batch suits small ops or continuous for big green pushes, they deliver.

Summing up, continuous pyrolysis plants outgreen batch systems—better energy use, lower emissions, higher yields, tighter controls. Handling plastics, tires, sludge? They turn waste woes into wins, like 45-52% oil from junk. In a world dumping 380 million tons plastics yearly, this tech’s key for sustainability. Pick continuous for eco-impact and profits; it’s the smarter path forward.

Continuous pyrolysis plant keeps running steady, slashing energy waste and emissions—up to 20-30% less than batch system starts/stops. Yields more too, like 45-52% oil, meaning less leftover junk.

Non-stop feeding in continuous pyrolysis plant means even breakdown, higher product quality—43-48% oil from plastics. Batch system? Uneven heat leaves more residue, less eco-friendly.

Yeah, if scaling up—faster ROI, 2-3 years, from energy savings and sales. But batch system’s cheaper upfront for small runs; continuous shines eco-friendly for big ops.

Both tackle tires, plastics, sludge—but continuous pyrolysis plant adapts to mixed feeds smoother, yielding 40% black from tires. Batch system suits uniform loads, but less eco-friendly overall.