If you’re dealing with waste from oil fields or refineries, you’ve probably run into oil sludge. It’s messy, harmful, and tough to get rid of. But what if you could turn that sludge into something useful, like fuel or carbon materials? That’s where an oil sludge pyrolysis system comes in. This tech heats the sludge without oxygen to break it down. In this post, we’ll break it all down for you— what it is, how it runs, and why it might fit your needs. Stick around. You’ll see how this approach tackles real problems in waste handling.

Oil sludge builds up in places like drilling sites and storage tanks. It’s a thick mix of oil, water, and solids. Think of it as the gunk left behind after oil operations. Not just dirty— it’s packed with bad stuff.

It shows up in oil production, refining, and even shipping. Drilling muds mix with crude oil. Tanks collect sediments over time. Spills add to the pile. In many spots, this waste sits around, leaking into soil or water. Governments call it hazardous for good reason. It has things like heavy metals and chemicals that can harm health.

The makeup changes by location. Some has high water, others more asphalt or gums. Common parts include hydrocarbons, sulfides, and phenols. These can cause big issues if not handled right. Density varies, so does oil content. That’s why testing matters before treatment. No two batches are the same.

Oil sludge isn’t just waste. It holds value if processed well. The hydrocarbons can turn into fuels. But dumping or burning it? That releases toxins. Better ways exist.

Pyrolysis means heating materials without air. It cracks big molecules into smaller ones. For oil sludge, this pulls out oil, gas, and solids. It’s been around for years in waste tech.

Burning needs oxygen and makes ash plus smoke. Dumping fills land and risks leaks. Pyrolysis? No oxygen, so less pollution. It happens in a closed setup. Heat breaks bonds at 400 to 600 degrees Celsius. Products: liquid oil, syngas, and char. Char is like carbon black— useful in other industries.

Studies show pyrolysis can be energy positive. That means it makes more energy than it uses, especially with dry feeds. For wet sludge, drying comes first. It’s a step up from old methods.

It cuts down on harmful releases. Meets strict rules on emissions. Turns hazard into resource. In places with tight land, it saves space. Plus, the end products sell. Oil for fuel, char for fillers. Gas heats the system itself. Smart loop.

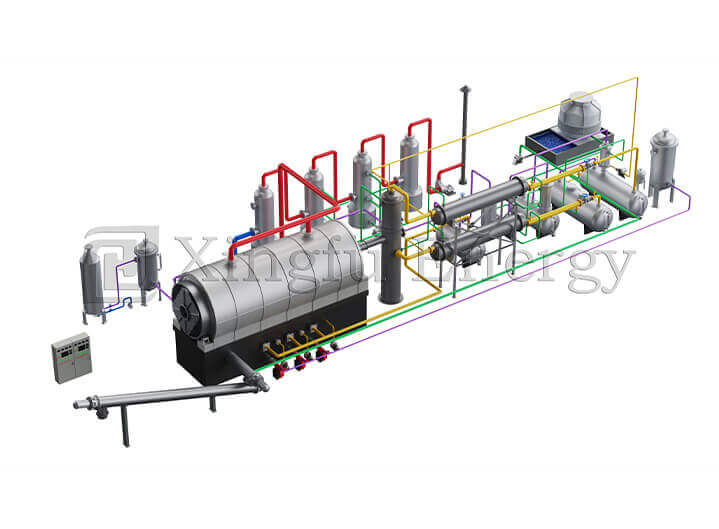

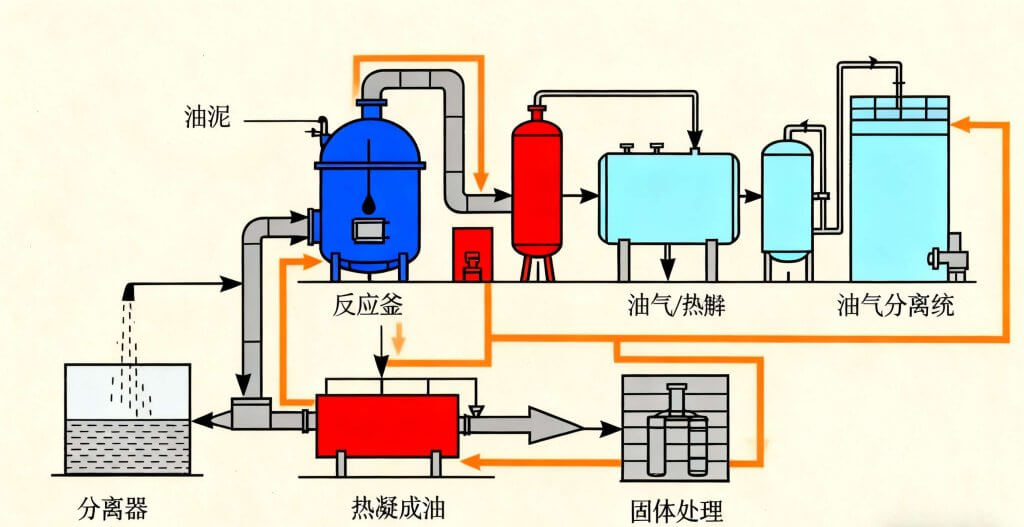

A system has several main pieces. They work together for safe, steady runs. Let’s look at them.

This is where heating happens. Often a rotary kiln or fixed bed. It spins or stirs the sludge for even heat. Walls get hot, but designs fight sticking. Sludge has gums that cling and coke up. Special scrapers clean inside, keeping flow smooth.

Heaters bring temps up slow. Burners use gas from the process. No outside fuel needed after start. Cooling condenses vapors into oil. Efficient ones catch most liquids.

Gases go through cleaners to remove bad bits. Then, back to burners. Solids discharge as char. Low oil left in it— under 3 percent to meet standards.

Here’s a simple table on main components:

| Part | Job | Why It Matters |

| Reactor | Breaks down sludge | Even heating, no clogs |

| Heater | Supplies heat | Uses own gas, saves costs |

| Condenser | Cools vapors to oil | High yield recovery |

| Scrubber | Cleans exhaust | Meets emission rules |

These parts make the system reliable. Good builds last years with little downtime.

Running one isn’t rocket science, but it takes care. Here’s the flow.

Check and test first. Remove big chunks if needed. Dry if too wet. Feed it in steady. No big preps often— straight from site.

Load into reactor. Heat climbs. No air inside. Sludge cracks. Vapors rise at certain temps. Light ones first, heavy later.

Vapors condense to oil. Gas cycles back. Char comes out dry. Monitor all. Adjust heat for best yields.

A full run might take hours or days, based on size. Continuous types run non-stop.

Cool down. Collect outputs. Test oil for use. Char for sale or soil fix. Minimal waste left.

It works because it’s controlled. Varies by sludge type, but yields can hit 40-50 percent oil.

Why bother with this? Plenty of upsides.

Less landfill use. Cuts toxins in air and water. Meets hazard waste codes like HW08. Harmless end products.

Sell oil and char. Gas powers the plant. Low running costs. Pays back quick in high-waste areas.

Bullet points on gains:

It builds your rep as a forward thinker. Clients notice green practices.

Not all smooth. Sludge sticks and cokes. But fixes exist.

Gums and asphalt cling to walls. Blocks flow, risks fires. Scraping devices solve it. They wipe clean during runs. No stops for scrub.

No fixed yields. Test each batch. Adjust settings. Labs help predict oil out.

Hot temps mean risks. Good seals prevent leaks. Train staff. Follow local laws on waste.

Innovations keep improving. Better catalysts speed cracks. Auto controls cut errors.

See it work worldwide. Plants in Europe handle tire sludge mixes. In Asia, oil field setups run daily. One in Turkey treats 15 tons, using gas treatment. Mexico has semi-continuous for 20 tons. Spain focuses on reactors. Finland batches 10 tons. Bulgaria feeds tires via belts. Malaysia installs full factories.

These show versatility. From batch to continuous. Electric or gas heated. All turn waste to value. Builds trust in the tech.

When you need solid gear for oil sludge pyrolysis, Qingdao Xingfu Energy Equipment Co., Ltd delivers. Started in 2010 in Qingdao, China, this firm builds and sells systems for waste like tires, plastics, and sludge. With a big team— over 200 folks, including engineers and welders— they cover design to setup. Their factory spans thousands of square meters. Products go to 30+ countries, from Mongolia to Spain. Certifications like CE and ISO back their quality. If you’re after dependable setups, they provide the know-how and tools.

An oil sludge pyrolysis system turns tricky waste into useful stuff. It heats without air, pulls out oil and char, and cuts harm. From prep to products, it’s a smart way to handle sludge. Benefits stack up— green, cost-saving, reliable. If waste piles up, this could change your game. Talk to pros for a fit.

An oil sludge pyrolysis system heats oily waste without oxygen to break it into oil, gas, and char. It works by loading sludge into a reactor, heating to crack molecules, then collecting outputs. Simple yet effective for cleanup.

This system stands out because it recovers resources like fuel from sludge. Unlike dumping or burning, it lowers pollution and meets tough rules. How it works: controlled heat avoids bad emissions.

Sticking and coking are common, but scrapers clean reactors during runs. Varying sludge needs testing. The system works by adjusting temps for each batch, keeping operations steady.

Yes, it adapts to changes in water or oil content. How it works: Test first, then tweak heat and feed. No fixed yields, but it pulls good results with care.

You get oil for fuel, char for fillers, and gas for heat. The system works by heating to vaporize, condensing liquids, and discharging solids. Yields depend on sludge, but often high value.