Waste tire pyrolysis provides an eco-friendly method for tire recycling. However, its severe operating conditions create major material problems. The process produces damaging gases like H₂S and HCl. It also works at very high heat, between 400-800°C. This fast-tracks damage types like sulfidation, chlorination, and thermal fatigue in boiler parts. Normal stainless steels often fail under these conditions. Therefore, advanced alloys like Inconel 625 or ceramic linings are needed for lasting toughness. This report looks at key damage processes, best material choices, and upkeep methods. These steps improve pyrolysis system dependability and service life.

Waste tire pyrolysis systems work under very tough conditions. These expose boiler parts to harsh chemical and heat settings. Knowing the main damage processes is vital. It helps pick the right materials and use good upkeep plans.

The breakdown of old tires makes a complicated mix of gases and liquids. This mixture includes hydrocarbons, water vapor, hydrogen sulfide (H₂S), hydrochloric acid (HCl), and other volatile organic compounds. These results are very reactive. They can start different damage forms such as sulfidation, chlorination, and acid attack. Also, sticky tarry stuff encourages fouling. This fouling further speeds up damage in specific spots.

Boilers in these systems often run at very hot levels. Temperatures range from 400°C to over 800°C. At these high heat levels, metals become more open to oxidation, carburization, and thermal fatigue. Repeated heating and cooling cycles can lead to tiny cracks. These cracks let damaging agents enter the material structure much easier.

Chlorine and sulfur stuff found in old tires greatly increase damage speeds. Chlorine causes pitting damage. Sulfur encourages sulfidation. Both harm boiler tubes and inside surfaces. Also, small amounts of metals like vanadium or sodium can form low-melting-point mixtures. These mixtures make hot damage worse.

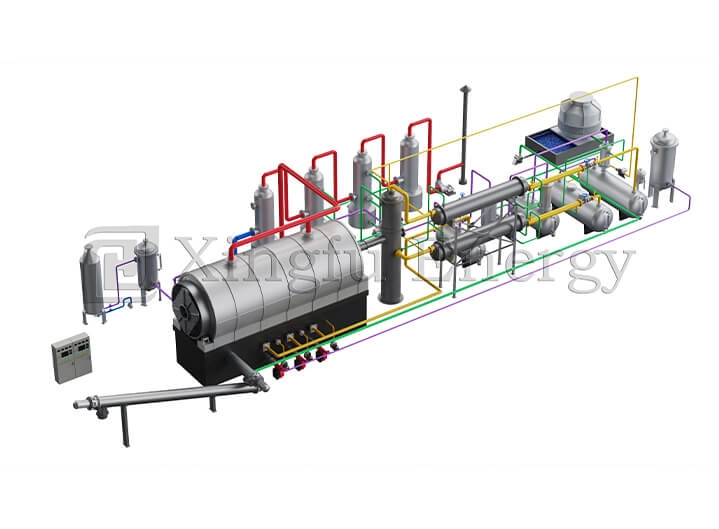

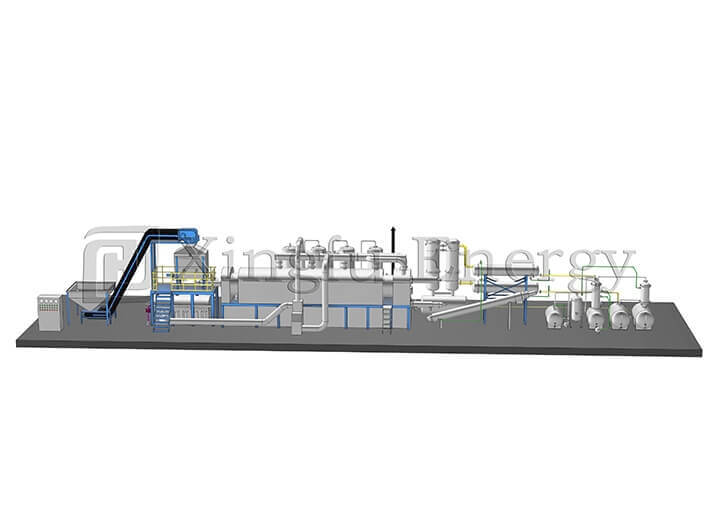

Qingdao Xingfu Energy understands these problems. They design systems using materials that resist damage. These materials can handle high heat and harsh chemical settings common in waste tire pyrolysis work.

Operating factors directly change how long boiler parts last. Knowing their effect is key to making materials work best.

Running at high heat increases oxidation speeds. Also, frequent starting and stopping causes thermal fatigue. This leads to protective oxide layers breaking off. Then, new metal surfaces get exposed to damaging agents. So, materials must be chosen for both high-heat strength and stability during cycling.

Pressure changes put stress on boiler walls and weld lines. When combined with harsh settings, this physical stress can speed up creep rupture or stress-damage cracking. Keeping pressure conditions steady is critical for long-term system soundness.

The makeup of old tire material can change a lot based on its source. Some might hold more chlorine or sulfur. This is due to additives used when making the tires. This difference leads to uneven gas mixes during breakdown. This unevenness affects how predictable the damage will be.

Qingdao Xingfu Energy tackles these issues. They build flexible systems able to manage different material feeds. These systems also keep mechanical stability when heat and pressure change.

Choosing the right stuff is a key part in reducing harm inside pyrolysis boilers. Both metal mixes and non-metal coverings are used. This depends on how severe the operating conditions are.

Grade 304 offers general damage resistance. But it may fail under high-chloride settings. Grade 316L is better here. Its molybdenum content improves resistance against pitting from chlorides. Grade 310S has more chromium (25%) and nickel (20%). This makes it right for high-heat uses because it resists oxidation very well.

Despite their pluses, normal stainless steels are not enough. This is true when facing constant high amounts of HCl or H₂S at high heat. They might suffer from grain boundary attack or faster pitting without extra shielding.

Nickel-based mixes like Inconel 625 or Incoloy 825 offer top resistance. They fight chloride-induced stress-damage cracking and sulfidation at high temperatures. Their high nickel amount keeps structure steady. This holds true even under long contact with harsh media.

Sprayed-on coatings (like aluminum-silicon) or ceramic barrier layers are often used over metal surfaces. They give an extra defense line against hot damage. This also extends time between upkeep cycles.

In very acidic areas or where metal harm is quick, ceramic tiles or composite linings work well. This is because they don’t react chemically. But they need exact fitting methods. This stops cracking when parts expand from heat.

Qingdao Xingfu Energy uses advanced mixes like Alloy 625. They also use ceramic-lined sections in crucial zones. This ensures long life even under extreme pyrolysis conditions.

A smart method balances performance needs with cost reality. This ensures the best material use over the boiler’s whole life.

Special alloys offer better results. But their price might not make sense for all parts. Engineers must focus on critical wear spots. These include heat exchangers or burning chambers. They get top materials. Meanwhile, cheaper choices work elsewhere.

New materials should work well with current parts. This stops galvanic damage or different expansion issues during use.

Designing parts for easy checking or swapping cuts downtime during planned upkeep. This is a key point for continuous pyrolysis work.

Qingdao Xingfu Energy helps clients through custom design talks. These consider both technical needs and long-term running costs.

What Maintenance Practices Help Extend Boiler Lifespan?

Active upkeep finds failures early. This stops them from becoming pricey fixes or system halts.

Regular visual checks plus non-harmful testing (like ultrasonic thickness checks) find thin walls or cracks early.

Leftover tar or carbon stuff builds up. It insulates surfaces unevenly. This creates hot spots and speeds up local harm. Routine cleaning stops these uneven buildups.

Advanced sensors measure heat differences, pressure changes, or gas mixes. These allow prediction models showing wear trends. This enables timely actions without needlessly stopping work.

Qingdao Xingfu Energy builds smart checking tools into its pyrolysis systems. These allow live diagnostics. This supports predictive upkeep planning.

With advanced engineering and proven solutions, Qingdao Xingfu Energy ensures stable and efficient pyrolysis processes.

Qingdao Xingfu Energy has wide experience. They create high-efficiency systems for old tire and plastic breakdown. These are made tough for harsh, damaging work settings.

By using advanced stainless steels like 310S and nickel mixes like Alloy 625 where needed, Qingdao Xingfu Energy ensures parts last long. This works even under harsh chemical exposure.

Each system is shaped based on material feed study. This ensures materials work well together. It also lowers total cost over time.

Choosing good damage-resistant stuff for old tire pyrolysis boilers needs knowing chemical exposures, heat changes, pressure forces, and material feed differences. High-performance mixes like Inconel 625 plus shielding coatings offer strong answers. But they must be used wisely, thinking about cost. With correct material picks backed by predictive upkeep ways—and guided by skilled providers like Qingdao Xingfu Energy—system dependability can be much better over long working lives.

The mix of chlorine and sulfur stuff made during old tire breakdown is the top source of fast boiler damage.

No. Grades like 304 or 316L offer general resistance. But they may fail under long contact with high-heat chlorides or sulfides. They need extra coatings or better alloys.

Important parts should be checked every six months using non-harmful testing methods. How often might rise based on how harsh the work is or how much the material feed c