The world faces growing environmental problems. It also urgently needs sustainable energy answers. New technologies like oil distillation are becoming vital tools. These tools help create a greener tomorrow. At Xingfu Energy, we see the important ability of oil distillation. It changes waste into useful energy supplies. This tackles both environmental harm and energy shortages. This blog looks at the key part oil distillation plays in making energy sustainably. It explains the steps involved, the good points, and real uses. It also shows how Xingfu Energy’s modern answers are leading this change.

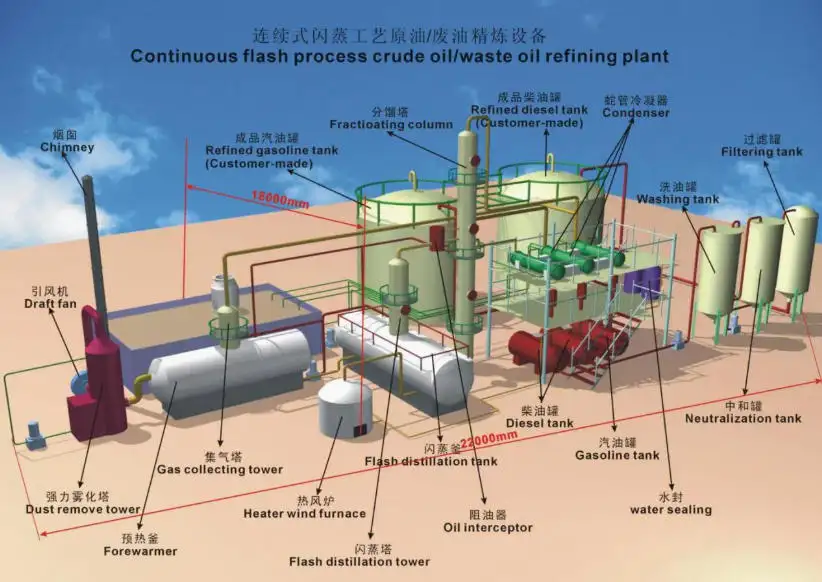

Oil distillation is an advanced method. It turns raw things like old tires, plastics, or unrefined oil into usable fuels. Examples include petrol and diesel. Workers heat the raw stuff inside a special chamber until it turns to gas. Then, they treat it with catalysts in another tower. This separates different oil parts. Next, these parts cool in a condenser. This makes purified liquids. Heavy fuel oil is a leftover product. Xingfu Energy’s product details show their plants get up to 90% oil. They also change all the waste, showing the method works very well.

The science relies on heat breaking things down and catalysts changing them. Workers heat waste stuff where no air is present. This breaks complex oil molecules into simpler ones. Then, catalysts make them even better. This pulls out valuable parts like diesel and petrol. Gases that don’t turn liquid can burn for heat. Leftover bits find new uses. This means almost nothing is wasted. This closed system is central to sustainable energy. It uses resources fully while lessening harm to nature.

Waste stuff piles up worldwide. Things like tires and plastics are a big environmental danger. Xingfu Energy’s papers note that waste tires grow as economies do. This makes recycling them vital. Oil distillation solves this by turning waste into precious energy goods. For example, Xingfu’s plants change old tires into fuel oil, carbon powder, metal wires, and gas. They do this without dirtying the air. This eases pressure on landfills. It also cuts down on nature damage.

A very strong point is making other fuels from waste. This cuts the need for limited fossil fuels. The oil from old tires and plastics runs factory boilers. Or, it can become petrol and diesel. This offers a renewable power source. It fits with worldwide work to use sustainable energy. It gives a real choice instead of old fossil fuels. It also helps with the energy problem.

Oil distillation backs the ideas of a circular economy. It recycles waste into things we can use again. Xingfu Energy’s method uses low heat and catalysts. It changes old tires, rubber, plastics, and oils into high-worth oil goods. The metal wires from tires are wanted for recycling. Carbon powder works in rubber items. This recycling way saves resources. It also creates money gains. This makes oil distillation good for both nature and business.

Oil distillation gives big nature gains. It cuts waste and bad outputs. Xingfu Energy’s sealed, hot designs stop dust and air dirt during work. Their many cooling steps make the most fuel oil with little waste. Changing waste into energy lessens the harm from dumping or burning. This helps make air and land cleaner.

The money potential is large. Xingfu’s plants get high oil amounts and change all waste. This means low-cost energy making. Also, the method creates useful leftovers. Carbon powder and metal wires sell or get reused. This makes extra money paths. Designs using hot air and saving heat lower running costs. This makes oil distillation a good choice for businesses wanting lasting and profitable answers.

Xingfu Energy’s plants are made to work well. Features like whole designs skip the need for special bases. This cuts setup time and expense. Sealed, hot feeding saves heating time and stops heat loss. The hot air heating uses energy best. These traits make sure oil distillation’s part in sustainable energy is safe for nature. It also uses power wisely.

Xingfu Energy has set up oil distillation answers around the world. This shows the real effect of this technology. Below is a table summarizing some of their successful cases. It shows how flexible and scalable their plants are:

| Location | Plant Type | Key Features |

| Turkey | 15T Fully Continuous Waste Tyre Plant | Syn gas treatment system |

| Mexico | 20T (2×10) Semi-Continuous Plant | Electric, syn gas treatment system |

| Spain | 15T Fully Continuous Plant | Reactor |

| Finland | 10T Batch Type Plant | Unloading in workshop |

| Bulgaria | 15T Fully Continuous Plant | Tyre feeding conveyor belt |

| Malaysia | 20T Fully Continuous Plant | Installation in factory |

These cases show how Xingfu Energy’s method fits different world needs. They use always-running plants for big jobs. Smaller tasks use batch systems. By putting in these answers, Xingfu helps countries cut waste, make lasting power, and help money growth.

Started in 2010 in Qingdao City, Shandong Province, Qingdao Xingfu Energy is a high-tech company. It is famous for knowing much about studying, making, planning, building, and selling factory boilers, strong containers, and systems for breaking down old tires and plastics. They have a strong study group with 78 tech experts, 28 planners, and 65 approved welders. Xingfu Energy covers 70,500 square meters total. This includes a 21,000-square-meter building space. Since 2012, the business has made over 100 million RMB selling inside China. They hold approvals like CE, ISO9001, and top boiler maker papers.

Xingfu Energy’s oil distillation and breaking plants go to over 30 lands. These include Mongolia, Indonesia, Korea, Malaysia, Poland, and Spain. They have a great name for being good and trustworthy. Their modern ways, like low-heat catalytic breaking and high-output distillation systems, put them as a world head. They deliver lasting energy answers through oil distillation.

The part of oil distillation in sustainable energy making is powerful. It offers a strong answer to two big problems: waste handling and energy lack. By changing waste stuff into valuable fuels and extras, oil distillation lowers nature harm. It lessens the need for fossil fuels. It pushes a circular economy. Xingfu Energy’s new ways and world cases prove the real-world effect. This makes it central to lasting progress. As businesses and leaders everywhere look for cleaner energy choices, oil distillation stands out. It is a tested, effective, and nature-kind answer.

Oil distillation has a vital part in sustainable energy making. It changes waste like tires and plastics into usable fuels. Examples are petrol and diesel. This process cuts landfill amounts. It lowers nature harm. It gives an option to fossil fuels. It backs a circular economy.

Xingfu Energy uses sealed, hot systems and many cooling steps. This stops dust and air dirt during oil distillation. Their plants make no bad outputs. This ensures a nature-kind method. It fits sustainable energy production aims.

Oil distillation can handle many things. This includes old tires, plastics, rubber, and unrefined oil. Xingfu Energy’s plants are adaptable. They deal with stuff like shopping bags, plastic wrap, and farm film. This makes fuel oil and other valuable extras.

Xingfu Energy’s oil distillation plants get up to 90% oil. They also change all waste. This makes them very effective. Things like hot air heating and heat saving designs boost energy use. This lowers running costs. It aids sustainable energy production.

Xingfu Energy is a dependable source. They have over ten years of work. They send goods to more than 30 countries. Their modern breaking and distillation ways, plus a strong study group and approvals like CE and ISO9001, promise steady, top-grade answers for sustainable energy production.