Tire pyrolysis is a method that heats old tires in a place without air. This breaks tires into tiny bits. It makes useful things like pyrolysis oil, carbon black, steel wire and syn gas. It’s a clever way to fix the problem of too many thrown-out tires. Also, it lets us use materials again.

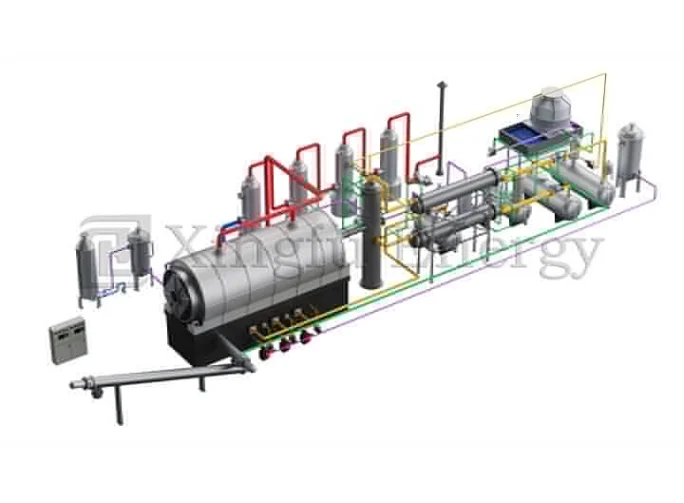

Pyrolysis machines turn used tires into stuff we can use again. First, tires are chopped into small pieces. Then, these pieces go into a pyrolysis machine. Then heated by hot air generated by the hot air stove. This makes gases that turn into liquid pyrolysis oil. Solid things, like carbon black and steel wire, are picked up separately. These machines use new tools to work well and keep the environment safe.

Pyrolysis oil is the main products of tire pyrolysis. This liquid oil is of higher calorific value. So, it can be used instead of fuels like diesel or furnace oil. Factories use it to make power or heat things. It’s also used to make chemicals. Because it’s so useful, pyrolysis oil helps us need fewer fuels from the earth.

Carbon black from tire pyrolysis is a soft powder. It’s used in many factories. For example, it makes tires and rubber stuff stronger. It’s also used in plastics and inks. Carbon black is cheap and saves money for companies. Plus, it helps use waste in a good way.

In tire pyrolysis, steel wires in tires are taken out as solid stuff. These wires are still tough. They can be reused for building things or other metal items. Reusing steel wire keeps it out of garbage dumps. It also means we don’t need to dig up as much new material.

Tire pyrolysis helps the planet by dealing with tire waste. It changes old tires into useful things. This means fewer tires pile up in landfills. It also stops bad gases from burning tires. The method matches global plans to handle waste better.

The things from tire pyrolysis are worth cash. Pyrolysis oil is cheaper than regular fuels. Carbon black cuts costs for making things like tires or plastics. Reusing steel wire saves materials and money. All these make tire pyrolysis a great choice for companies.

New pyrolysis machines are leading the way in tire recycling. These machines use top-notch tools to work better. For example, they have systems that control heat and pressure exactly. This saves power and makes more products like pyrolysis oil, carbon black, and steel wire. These systems also make fewer mistakes, so the products are always good.

Also, modern pyrolysis machines are kind to the environment. They have special exhaust cleaning system to catch and clean bad gases. This follows strict rules for keeping nature safe. These new ideas make the process cleaner and cheaper.

How well a pyrolysis machine works changes the amount and quality of products. Good machines spread heat evenly inside. This breaks down tire materials fully. So, we get more pyrolysis oil and carbon black.

Plus, strong machines have great systems to turn gases into liquid oil without losing much. These systems use every part of the tire. This cuts waste and makes more money. Machines built with tough parts last longer and work better, which helps make top-quality products.

Pyrolysis oil is one of the most flexible products from tire pyrolysis. Its strong energy makes it a good swap for fuels like diesel or furnace oil. Power plants use it to run machines like turbines and boilers because of its high calorific value

Besides making power, pyrolysis oil is used to make chemicals. Its makeup lets it be turned into things like paints, glues, and cleaning liquids. Since it works in so many ways, pyrolysis oil is key for many industries.

Carbon black from tire pyrolysis has lots of uses in factories. It’s mostly used to make rubber things, like tires, stronger and last longer. It’s also used in plastics as a color or filler.

The ink world likes carbon black because it gives deep colors for printing. Plus, it’s used in coatings to make surfaces tougher and protect them from the sun. Using carbon black helps companies save cash and care for the planet.

A pyrolysis machine is special made to recycling the used tyres. It makes useful things like pyrolysis oil, carbon black, and steel wire without burning the tires.

Good machines handle heat and gas processes well. This leads to more useful stuff, like oil and carbon black, from tires.

Pyrolysis oil is used in power plants to run turbines and boilers. It’s also used in chemical factories to make paints, glues, and cleaning liquids.

Carbon black makes rubber things like tires stronger. It’s a color in inks and a filler in plastics. It also helps coatings last longer.

For more info about Qingdao Xingfu Energy Equipment Co., Ltd., in Qingdao city since 2010, experts in waste tire & plastics pyrolysis systems, just reach out!