Hey everyone, ever think about those worn-out tires stacking up in your shed or the local mechanic’s place? They aren’t just bulky junk. If we don’t handle them correctly, they become a genuine environmental problem. Recycling tires isn’t just a trendy phrase. It’s a hands-on method to transform waste into valuable things. In this write-up, we’ll explore why recycling tires matters so much. We face gigantic piles of thrown-out tires yearly. We’ll examine the environmental gains. We’ll also see how it preserves resources. Plus, we’ll cover the financial advantages. Stick with us. By the finish, those used-up radials might look totally different to you.

Tires last a long time—really. Made from rubber, artificial materials, and chemicals, they refuse to decay like everyday garbage. Tossed in landfills, they linger for decades. Maybe centuries. They leak harmful substances into dirt and water sources. I’ve viewed photos of illegal tire piles becoming perfect spots for mosquitoes. Trust me, nearby towns suffer. Illnesses like Zika or West Nile? Absolutely. Those insects adore the motionless water trapped in old tires.

But here’s the real problem: Bad disposal isn’t merely local. Around the world, we discard billions of tires every single year. Just in China, thrown-out tires reach millions of tons annually. This worsens wider pollution headaches. Recycling changes everything. It stops tires from hitting dumps. Instead, they become cushioning for playgrounds, road materials, or even power sources. Consider this: Recycling a single tire saves power equal to a full day’s home electricity use. That’s solid proof. Real results.

Let’s also remember fire dangers. Tire mounds can catch fire. They might burn for many days. Poisonous smoke pours out. Recall that enormous tire fire in Virginia during the 1980s? It blazed for months. The cleanup cost millions. Recycling stops that horror.

Looking closer, the environmental harm is enormous. Tires buried in landfills occupy precious room. We can’t spare that space. It could become parks or crop fields. When tires break down (very slowly), they leak chemicals. Substances like benzene and heavy metals escape. These poison underground water. I’ve spoken with people at recycling centers. They’ve noticed rivers near dump sites turning cloudy from runoff. Truly ugly.

Openly burning tires? Much more terrible. It pumps thick black smoke packed with poisons. Air quality suffers. Climate change worsens. Emissions from tire fires are deadly serious. They pile onto the greenhouse gases we aim to reduce.

Proper tire recycling, however, slashes these threats. Methods like pyrolysis—heating tires without air—break them into oil, gas, and carbon black. No open flames. No huge pollution releases. It’s like granting tires another life minus the chaos. In spots like Qingdao, China, where factory waste is critical, this approach is catching on. Plants there handle countless tons. They convert possible pollutants into practical goods.

Tire recycling delivers strong benefits across several fronts. Let’s detail them with hard facts:

Resource Protection:

Tires hide treasure troves of materials. Recycled tire rubber goes into fresh items. This spares untouched resources. For example, recycling one tire provides sufficient rubber for a welcome mat. Or part of an athletic track surface. Worldwide, this reduces mining for natural rubber. Such mining frequently wrecks rainforests.

Power Conservation:

Making brand-new tires swallows huge energy—oil and electric power. Recycling needs far less. Roughly 70% less energy per tire. That’s like skipping millions of oil barrels yearly.

Financial Lift:

Jobs, people. Recycling centers create work. Positions in gathering, handling, and making things. Across America, the tire recycling field employs beyond 100,000 individuals. In China, it’s larger still. Factories ship recycled materials globally. Also, selling recycled items like crumb rubber earns cash—sometimes $1 billion every year in certain markets.

Health and Safety Upsides:

Fewer mosquito zones mean fewer sickness outbreaks. Cleaner air from less burning? Easier breathing for everybody. Simple logic.

To picture the advantages, see this fast chart comparing tire disposal ways:

| Method | Environmental Impact | Cost | End Products |

| Landfilling | Heavy pollution, wasted space | Cheap start, costly later | Nothing |

| Incineration | Air poisons, bad emissions | Medium | Dirty energy |

| Recycling/Pyrolysis | Low emissions, saves resources | Pricey setup, profitable long-term | Oil, gas, carbon black |

See? Recycling shines. But it’s not perfect. Some techniques need upgraded tech to manage impurities like tire steel wires.

Wondering about the actual steps? Recycling tires begins with gathering. Picture drop spots at repair shops or home collection services. Then comes shredding: Machines slice tires into chunks. Rubber separates from steel and fabric.

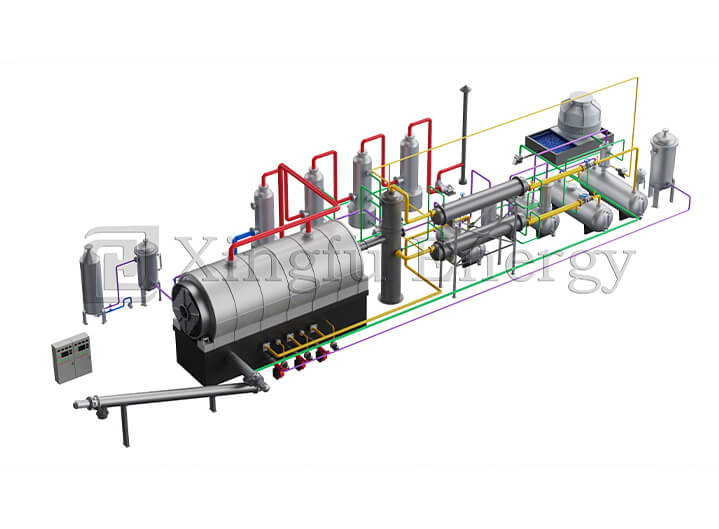

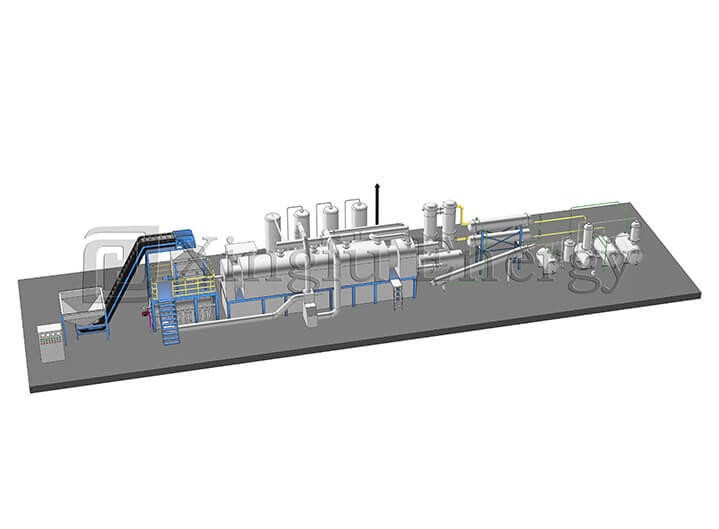

Next, the wonder happens. Mechanical recycling crushes rubber into tiny grains. These work for asphalt or fake grass. Chemical ways, like devulcanization, split rubber bonds. Then it fits into new tires. But pyrolysis? That’s where things get sophisticated. Tires heat to 400-500°C inside sealed, air-free chambers. This produces:

Fuel oil: Around 40-45% output, ideal for factory heaters.

Carbon black: Roughly 30-35%, used in printer inks or fresh tires.

Steel wire: About 10-15%, recycled as metal goods.

Syngas: Approximately 5-10%, burned for power.

I toured a facility once. They demonstrated this. The scent of new oil from the line was unexpectedly clean. Nothing like burning rubber. Real-world cases show a 10-ton batch can generate oil sufficient for a small factory’s power needs.

Side point: Tires differ. Car tires recycle simpler than truck ones. Truck tires hold more steel. But new ideas are solving that.

It’s not perfect. Collection can be poor in country zones. Starting a pyrolysis plant costs millions. Also, recycled oil prices swing. They link to crude oil costs. This can harm earnings.

But successes exist. Across Europe, laws require 95% tire recycling. This leads to almost no waste. China? They’re growing fast. Plants manage 20,000 tons each year. A contact in the business described a Qingdao factory. It changes waste into export-quality carbon black. Truly motivating. It displays how rules and technology unite.

Occasionally projects fail. Neighbors might oppose them fearing bad smells. Teaching people helps. Most modern plants seal completely tight.

Speaking of breakthroughs, focus on Qingdao Xingfu Energy. Located in Qingdao, China, they’ve produced waste tire and plastic pyrolysis setups since 2010. They employ over 200 staff. Their huge 20,000-square-meter base masters turning scrap into riches. Their systems manage semi-continuous to fully automatic operations. They process 60 tons daily. Imagine high-output reactors. These pull out 40-45% fuel oil with very little pollution. They’ve sent gear to 30+ nations. They win praise for reliability and eco-design. If you want tire recycling equipment, Xingfu is the source. They mix deep know-how with sturdy machinery.

Summing up, tire recycling’s importance is clear. It shields our planet. Plus, it pulls value from trash. This isn’t just green speak. It’s about work positions, public wellness, and smarter material use. Whether through basic shredding or complex pyrolysis, every reused tire matters. If everyone joins in—firms, leaders, you and I—we can control the tire waste disaster. Eager to help? Begin by finding local recyclers. Or look into tech like pyrolysis. Your bald tires might actually fuel tomorrow.

Recycling tires is essential. It halts landfill poisons. It cuts emissions. Without it, tires leak toxins and breed pests. Recycling converts them into helpful items. Think fuel or ground cover. This massively reduces waste.

Pyrolysis heats tires with zero air. It makes oil, gas, and carbon black. It’s a clean recycling path. Yields run high—up to 45% oil. Pollution stays minimal. This shifts large operations dramatically.

Totally! Bring old tires to recycling spots or auto stores. Some spots pay small amounts. It’s simple and impactful. I did it with my winter tires. Felt great knowing they avoid rotting dumps.

It builds jobs in processing. It lifts markets for recycled goods. Plants profit selling oil or carbon black. One place I know makes thousands per batch after expenses.

Yes. Advanced tech setup is expensive. Material quality varies sometimes. But pluses beat minuses. Methods keep improving. Wider collection systems would really spread it.