Running an oil distillation plant isn’t just about flipping switches. It’s a mix of science, safety, and smart planning that turns raw materials into valuable fuels. If you’re stepping into this field, whether as a new operator or someone scaling up operations, this guide walks you through the essentials. We’ll cover everything from setup to daily runs, drawing on real-world practices in waste recycling and energy recovery. Let’s dive in.

Oil distillation breaks down complex mixtures into simpler parts. Think of it as cooking down a stew to separate flavors. In the industry, it refines crude oils from sources like waste tires or plastics into usable diesel or other fuels.

The process relies on heat. You heat the oil to vaporize lighter parts, then cool them to collect pure fractions. This happens in tall columns where temperatures drop as vapors rise. Key here is controlling the boil. Too hot, and you burn everything. Too cool, and nothing separates.

Distillation plants handle various feeds, from pyrolysis oils to used motor oils. Each type needs tweaks. For instance, pyrolysis-derived oils often carry impurities like sulfur, so pre-treatment steps matter a lot.

Waste piles up fast. Tires and plastics clog landfills. Distillation turns that junk into fuel, cutting waste and creating value. It’s cleaner than burning straight up, with less smoke and ash. Plus, it fits into green energy trends. Businesses save on disposal costs while selling refined oil. That’s a win for the bottom line and the planet.

Before you run anything, build a solid foundation. Setup takes time, but get it right, and operations flow smooth.

Pick a spot with easy access to raw materials. Near highways or ports helps with shipping in waste and out fuel. Check local rules on emissions and zoning. You don’t want shutdowns over permits.

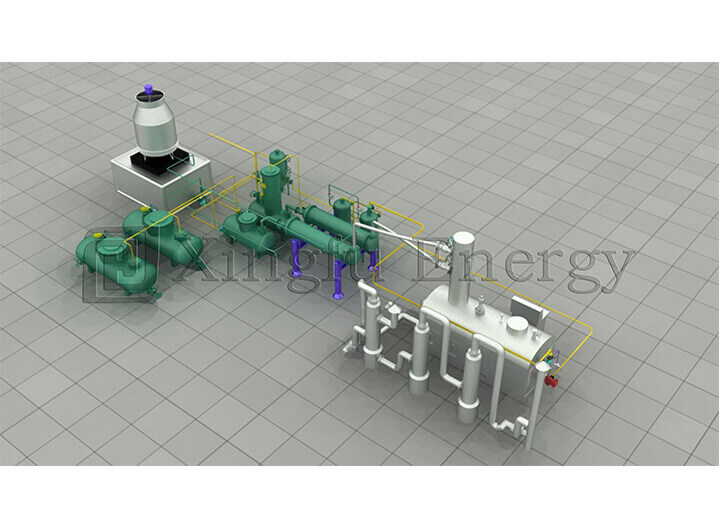

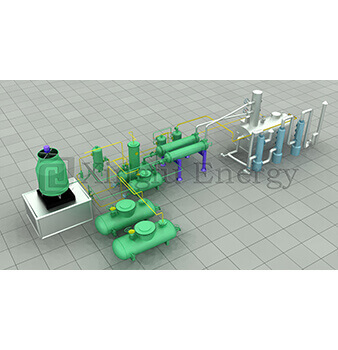

For gear, focus on reliable parts. A good reactor handles high heat without leaks. Condensers cool vapors quick. Pumps move fluids steady. Size matters too—start small if you’re testing, go big for volume.

Here’s a quick table on key equipment needs:

| Equipment | Purpose | Key Feature to Look For |

| Distillation Column | Separates oil fractions | Tall design for better separation |

| Heating System | Provides controlled heat | Even temperature distribution |

| Cooling Unit | Condenses vapors | Efficient heat exchange |

| Storage Tanks | Holds raw and finished oil | Leak-proof with safety valves |

People make the plant tick. Hire folks who know chemistry and mechanics. Train them on safety drills. A good operator spots issues early, like odd smells or pressure drops. Rotate shifts to avoid burnout. Strong teams build your reputation—word spreads when operations run without hitches.

Once set up, the real work begins. Running the plant means constant checks and adjustments. Stay sharp.

Start with clean feed. Sort waste to remove metals or dirt. Crush tires into chunks for even heating. Test the oil for water content—too much, and it foams up. Dry it if needed. This step sets the tone for the whole run.

Fire up the heater. Bring the oil to boil slowly. Vapors rise through the column, condensing at different levels. Light fuels like gasoline come off first, heavier diesel later.

Monitor gauges. Pressure too high? Vent it safe. Temperature off? Adjust burners. Collect fractions in separate tanks. Run tests on each batch for purity. If it’s cloudy, re-distill.

Bullet points for a typical daily routine:

It’s hands-on. One slip, and yields drop.

Distillation leaves sludge. Don’t dump it—recycle where possible. Carbon residues can sell as filler. Gases? Burn them for plant heat. Keep emissions low with scrubbers. Track everything. Good records prove you’re compliant and help tweak future runs.

Safety isn’t optional. One mistake can shut you down or worse.

Hot oils splash. Vapors ignite. Always wear gear—gloves, goggles, suits. Install fire suppressors everywhere. Train on spills: contain, then clean.

Pressure builds fast. Use relief valves. Check them weekly. Electrical faults? Ground all equipment.

Have plans ready. Fire? Evacuate and call help. Leak? Shut valves quick. Drill monthly. Know your exits. A calm team saves lives.

Machines wear out. Regular care keeps them going.

Oil filters clog. Clean them often. Lubricate moving parts. Spot rust early—paint over it.

Schedule downtime. Once a month, inspect the column inside. Replace worn seals.

Tech changes. Add automation for better control. Sensors alert on issues. It cuts labor and boosts output. Watch industry trends—new catalysts speed things up.

Money talks. Run smart to profit.

Raw materials eat budget. Buy in bulk. Energy bills? Use waste heat. Labor? Train in-house.

Track costs vs. sales. Aim for high yields—45-50% oil from feed is solid.

Word gets around. Deliver clean fuel on time, and customers return. Share success stories—case studies from places like Europe or Asia show reliability. Build a name for quality. It draws investors and partners.

Efficient runs cut waste, appeal to green buyers. Certify your process—ISO stamps build trust.

When it comes to reliable gear for oil distillation, Qingdao Xingfu Energy Equipment Co., Ltd stands out. Founded in 2010 in Qingdao, China, this high-tech firm focuses on building and selling systems for waste tire and plastic pyrolysis, plus oil distillation setups. With over 200 workers and a big factory space, they’ve shipped to more than 30 countries, earning praise for sturdy equipment. Their team includes skilled engineers who handle everything from design to install. If you’re looking for proven solutions, they offer the tools to get your plant running strong.

Running an oil distillation plant blends skill, care, and smart choices. From setup to safety, each part builds toward steady output and profits. Stick to these steps, and you’ll turn waste into wealth while growing your operation’s name. Ready to take the next step? Reach out to experts for tailored advice.

To run an oil distillation plant, start with site selection and permits. Then, install equipment like columns and heaters. Train your team on basics before firing up.

Safety in running an oil distillation plant means daily checks, proper gear, and emergency drills. Focus on pressure control and fire prevention to keep things smooth.

When running an oil distillation plant, yields vary by feed, but aim for 45-52% refined oil. Good prep and monitoring boost those numbers.

Maintenance keeps your oil distillation plant running without breaks. Regular cleans and fixes prevent costly downtime and extend gear life.

To improve profits in running an oil distillation plant, cut costs on materials and energy. Sell byproducts and market your clean fuels to build a strong customer base.