Hey, if you’re in the waste management game or just curious about turning trash into treasure, pyrolysis of plastics is one hot topic right now. Picture this: mountains of plastic waste piling up, choking landfills and oceans. But pyrolysis? It’s like a magic trick that heats up those plastics without oxygen, breaking them down into fuels, chemicals, and even carbon black. Sounds great, but it’s not all smooth sailing. I’ve dug into the nitty-gritty—from global stats to shop-floor headaches—and pulled together this guide on the challenges and solutions. We’ll use real numbers, like the 380 million tons of plastics churned out in 2018 alone, and stories from Chinese ops where this tech is booming. Stick around; by the end, you’ll see why it’s worth the hassle.

Let’s start simple. Pyrolysis is thermal decomposition—heat plastics in a sealed reactor, no air involved, and watch them crack into smaller bits. No burning, just breaking bonds. End products? Oil for fuel, syngas for energy, and carbon black for tires or inks.

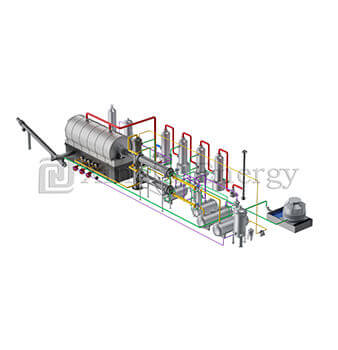

The process kicks off with shredding mixed plastics—think bottles, bags, wrappers—then feeding them into a reactor at 400-600°C. Vapors condense into oil, gases get captured, solids leftover. In China, where plastic waste hits 14% of municipal solid waste by 2030 estimates, this tech’s exploding. Recycling rate? A measly 9%. Pyrolysis steps in for the tough stuff that mechanical recycling skips.

I remember chatting with a plant manager; he said their setup handles 50 tons a day, turning headache waste into cash. But why bother? Landfills leak toxins, incineration spews dioxins. Pyrolysis cuts emissions, recycles energy,and it could grow 25% yearly. Yet, pulling it off ain’t easy.

Globally, we’ve made 6.3 billion tons of plastics since 1950. China? Leads the pack, with municipal solid waste ballooning. By 2030, plastics could be 14% of that MSW stream. Most ends up buried or burned openly—carcinogens in the air, microplastics in water.

Composition matters too. In Chinese cities, polyethylene and polypropylene dominate—perfect for pyrolysis, yielding high oil. But mixed with PVC or PET? Contaminants galore. Low recycling? Blame collection costs and variety—colors, sizes, types make sorting a nightmare.

Prospect? Huge. Pyrolysis turns low-value waste into high-calorific goodies. In Europe and Asia, plants are popping up, exporting tech to Africa, Latin America. But scaling? That’s where the rubber meets the road—or doesn’t, if you hit snags.

No sugarcoating: pyrolysis has hurdles. From tech glitches to money woes, these can tank an op. Let’s break ’em down.

Feeds vary wildly—long-chain hydrocarbons, waxes, toxins. One batch clean, next filthy with metals. Breaking ’em down needs precision; mess up, and product quality tanks.

In a Henan plant I heard about, inconsistent plastics led to 20% yield drops. Risks? Failures if not handled right. Calcium, sodium hitch rides, fouling everything.

Pyrolysis oil’s acidic, oxygen-hungry—eats equipment alive. Co-process with contaminants? Heavy fouling on catalysts, pipes. Replacements? Costly, downtime killer.

One study on Chinese processes showed corrosion slashing lifespans by half. Fouling plugs lines, hikes energy use. In batch setups, it’s worse—cleanouts eat time.

Profit’s the biggie. Feedstock cheap, but ops expensive—energy, maintenance. Oil prices fluctuate; drop below $50/barrel, and you’re underwater.

A report compared four Chinese methods: yields 43-52% oil, but capex high. Subsidies help, but without ’em? Tough sell. And viability long-term? Questions linger if markets don’t stabilize.

Demand’s sky-high, but supply lags. Feedstock inconsistent, tech scarce, costs steep. Timelines tight—new plants need years. Space? Cramped facilities can’t expand easy.

In continuous ops 50-ton rotary kiln, scaling means bigger reactors, more heat. But flexible? Not always. One African export stalled on logistics—parts delayed months.

Oh, and a side thought: ever wonder why some plants thrive while others flop? Often, it’s ignoring local regs early on. Sneaky fines add up.

Water cools, cleans—but guzzles energy. Access spotty in dry zones. Pollution? Hydrocarbons, minerals leak into streams if not managed.

A Qingdao setup used 10% of ops budget on water treatment. Pollutants? Tricky to trap, risks fines or shutdowns.

Good news: solutions exist. Tech advances, clever tweaks make it work. Let’s match ’em to challenges.

Use advanced separators—centrifugals pull contaminants pre-pyro. Catalysts crack tough chains evenly. In thermal-catalytic, yields steady at 43-48% oil.

Corrosion-resistant alloys—hastelloy, not steel. Regular flushes, anti-foul coatings. For catalysts, regen cycles cut buildup.

In batch, hydroseals recycle gas, reduce oxygen exposure. One plant extended equipment life 2x with these.

Integrate value chains—sell oil, black, gas direct. Subsidies in China help; export models cut costs.ROI? 2-3 years if oil at $60/barrel.

Modular designs—add units as needed. Rotary kilns scale horizontal, save space.

Partner for feedstock—contracts with waste collectors ensure supply. In Southeast Asia, plants hit 200 tons/day this way.

Efficient coolers—plate heat exchangers recycle water, cut use 30%. Treat effluent with membranes, zero discharge.

For instance, some companies handles this—less steel, lower install costs. One US pilot slashed water bills half.

These ain’t pie-in-sky; Chinese firms lead, exporting to 30+ countries.

If you’re eyeing pyrolysis gear, check Qingdao Xingfu Energy Equipment Co.,Ltd. Founded 2010, they’ve got 21,000 square meters of plant space, 228 workers—including 78 tech whizzes. Specialize in waste tire and plastic pyrolysis systems, plus boilers, vessels.

Strong R&D: 18 senior pros, 40+ big machines. Exported to Mongolia, Indonesia, Korea—30 countries total. CE, ISO9001 certified, sales topped 100 million RMB since 2012. Their setups? Semi-continuous to fully auto, capacities 8-30 tons. High rep for quality, custom designs. If mixed plastics bog you down, their kit turns ’em into oil, black, gas—efficient, green.

Wrapping up, pyrolysis of plastics flips waste into wins—cutting landfill loads, curbing emissions, birthing fuels. Challenges like feeds, corrosion, cash flow? Real, but beatable with tech tweaks, smart planning. From Chinese giants yielding 45%+ oil to global growth at 25%, it’s viable. Pick right partners, mind details, and you’ll thrive. Time to act; plastic piles won’t wait.

Costs bite—feedstock, energy. But sell oil at 45-52%, black at 30%; ROI hits 2-3 years. Subsidies help; integrate sales for profit. Seen ops where ignoring this tanks ’em.

Yep, modular kilns add capacity without huge overhauls.Ensures steady supply, meets demand spikes.

Guzzles for cooling, risks pollution. Recycle via exchangers, cut use 30%. Membranes treat waste—zero discharge. Keeps ops green, avoids fines.