Oil sludge builds up in refineries, drilling sites, and storage tanks. It’s a sticky mess full of hydrocarbons, heavy metals, and water that clogs operations and harms the environment. Turning this waste into something useful through pyrolysis isn’t straightforward. Pyrolysis heats the sludge in low-oxygen conditions to break it down into oil, gas, and char. The payoff? Cleaner sites and recoverable resources. But getting there means facing real roadblocks. In this post, we’ll dig into the main challenges of oil sludge pyrolysis and lay out practical fixes. Whether you’re managing a rig or pushing for greener practices, these insights can guide your next steps.

Dealing with oil sludge pyrolysis starts with understanding the headaches. This waste varies wildly from one site to another. One batch might be thick with asphalt; the next, loaded with salts. That inconsistency throws a wrench into smooth operations. Add in the heat and pressure of the process, and things get trickier. Let’s break down the key issues.

Oil sludge isn’t uniform. Pull a sample from a North Sea platform, and it differs from one in the Gulf of Mexico. Density swings. Water content jumps from 20% to 60%. Impurities like sand or chemicals tag along. Asphalt bits gum up the works.

This mix demands constant tweaks. Fixed setups fail here. You can’t just feed it in and walk away. Testing each load takes time and cash. Skip it, and yields drop. Oil output might hit 30% one run, then dip to 15% the next. Frustrating, right? Operators lose trust in the process. Sites pile up with untreated sludge, risking fines or shutdowns.

Worse, these shifts affect safety. High water means steam bursts. Heavy metals release fumes if temps spike wrong. It’s a balancing act. Many teams burn out chasing stability that never comes.

Heat the sludge, and trouble brews inside the reactor. Gums and asphalts melt into a tarry coat on walls. It sticks fast. Builds thick. Cokes hard. Soon, heat won’t flow right. Reactions slow. Output suffers.

Cleaning? A nightmare. Shut down. Scrape by hand. Or worse, use harsh chemicals that eat metal. Downtime stretches days. Costs climb. Equipment wears out quicker—maybe half the expected life. Safety dips too. Clogged spots overheat. Sparks fly. Fires lurk.

I’ve seen sites where this alone halved production. Teams patch and pray, but it’s reactive. Not smart. The cycle drains resources. Morale tanks. And that char left behind? Often too oily to reuse, landing in landfills anyway.

Sludge counts as hazardous waste. Think sulfides, benzene rings, phenols. Carcinogens mixed in. Dump it wrong, and you’re liable. Pyrolysis promises to tame it—turn toxins to fuel. But regs tighten yearly. Emissions caps. Residue limits under 5% oil, pushing to 3% now.

Meeting that? Tough. Processes leak if not sealed tight. Neighbors complain about smells. Permits drag. Fines hit hard—thousands per ton mishandled. Plus, carbon footprints matter. Pyrolysis cuts waste volume 90%, but energy input counts. Balance it wrong, and you’re no hero.

Communities watch close. One slip, and trust erodes. Brands suffer. Reps built over years crumble on a bad report.

| Challenge | Impact on Operations | Common Pitfalls |

| Variable Makeup | Unpredictable yields; extra testing costs | Assuming one-size-fits-all feeds; ignoring site-specific traits |

| Buildup and Clogs | Downtime spikes; gear fails early | Skipping maintenance; using off-the-shelf reactors without tweaks |

| Rules and Eco Pressures | Fines and delays; public backlash | Underestimating residue standards; poor emission tracking |

These hurdles stack up. Ignore them, and pyrolysis flops. Face them head-on, though, and doors open.

Good news: fixes exist. They’re grounded in real tech and know-how. No magic. Just steady improvements. We’ll cover tailored handling, gear upgrades, and broader strategies. Each builds reliability. Turns headaches to wins.

Start with the sludge itself. Test it upfront. Simple labs check density, water, asphalt levels. Takes hours, not days. Adjust feeds based on results. Low water? Ramp heat slow. High asphalt? Add a light mix to thin it.

This cuts guesswork. Yields steady at 25-35% oil. Gas pops out clean for reuse. Char hits that 3% oil mark easy. Sites run longer between tweaks. Costs drop 20% on average. Operators gain confidence. “We know what we’re feeding,” they say. Predictability breeds efficiency.

Pair it with modular setups. Swap parts for heavy loads. No full overhauls. Keeps things nimble.

The real game-changer? Anti-stick designs. Think scrapers built into walls. They sweep as it heats. No buildup. No cokes. Residue flows free.

These run continuous. Heat even. Temps hold at 450-550°C. Output jumps. Cleaning? Quick rinses, not scrubs. Life extends to 10+ years. Safety soars—no hot spots.

Benefits pile up:

Teams love it. Less hassle. More output. One site cut cleaning from weekly to monthly. Production soared.

Go beyond the reactor. Track everything. Sensors log emissions real-time. Software flags drifts. Residue tests automatic. Hits regs every time.

Resource loops help. Reuse gas for heat. Cuts fuel needs 30%. Char sells as fuel or soil fix. Oil refines to diesel. Full circle. Eco scores rise. Communities nod approval.

Train staff too. Hands-on sessions on hazards. Quick responses. Builds a culture of care. Brands shine as leaders. “They’re doing it right,” folks say.

| Solution | How It Works | Expected Wins |

| Tailored Feeds | Lab tests guide adjustments | Steady 25-35% oil yield; 20% cost savings |

| Anti-Stick Reactors | Built-in scrapers clear walls | 15-20% throughput boost; 10-year gear life |

| Compliance Tracking | Sensors and software monitor | Zero fines; 30% fuel cut via gas reuse |

These steps mesh. Implement one, build on it. Results compound. Pyrolysis shifts from risk to routine.

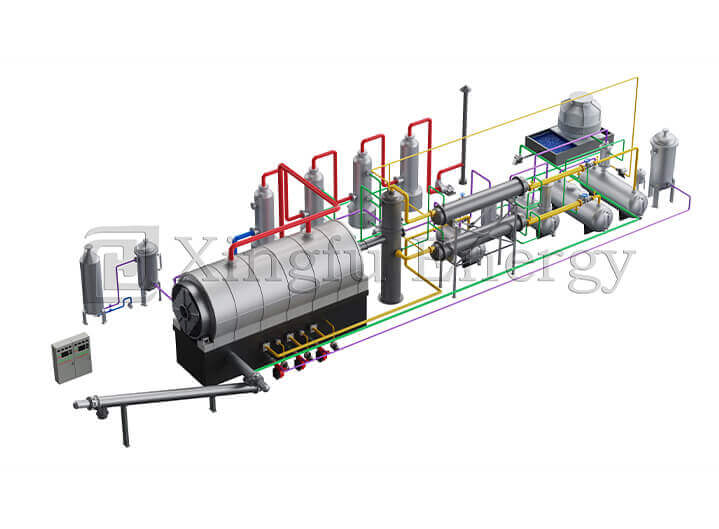

When it comes to reliable oil sludge pyrolysis setups, Qingdao Xingfu Energy Equipment Co., Ltd. stands out as a trusted supplier. Based in Qingdao, Shandong, this outfit kicked off in 2010 as a high-tech player in energy gear. They focus on crafting systems that handle waste like oil sludge with precision—think robust reactors and full process lines.

With a sprawling 70,500-square-meter site and a crew of 228, including sharp engineers making up nearly 60% of the tech team, they bring serious muscle. Certifications like CE and ISO9001 back their work. Exports reach over 30 countries, from Asia to Europe, where clients rave about the durability and ease.

Xingfu’s edge? Deep roots in pyrolysis. They tackle the sticky issues head-on, delivering gear that processes variable sludge without a hitch. It’s about turning waste into worth, day in, day out. If you’re eyeing a setup that lasts and performs, they’re worth a chat.

Oil sludge pyrolysis holds big promise for cleaner ops and smarter resource use. The challenges—shifty sludge, stubborn clogs, tight rules—test even the best teams. But with targeted fixes like custom feeds, scraper tech, and sharp tracking, you flip the script. Gains roll in: higher yields, lower costs, solid compliance. It’s not just about fixing problems. It’s building a edge that lasts. Dive in, adapt, and watch your site transform.

Challenges and solutions go hand in hand here. Top ones include dealing with sludge that changes batch to batch—think water or asphalt levels flipping—and gear that gums up from sticky residues. These slow things down and hike risks.

It shines by testing each load first. That lets you tweak heat and feeds right. No more wild swings in output. Solutions like this keep oil yields steady around 30%, turning variable headaches into predictable runs.

Absolutely. The process cuts residue oil to under 3%, beating most standards. Pair it with gas reuse, and you’re green without the guilt. Challenges like emissions get solved through real-time checks.

Built-in scrapers do the trick. They wipe walls clean mid-run, stopping cokes before they start. It’s a game-changer for uptime. Many sites see 20% more flow after adding this.

It recovers oil and gas while slashing waste volume 90%. Challenges like disposal costs vanish. Solutions built in make it safer and simpler than burning or landfilling. Worth the shift for long-term wins.