In the field of chemical work, distillation columns play a big role in splitting organic stuff. They deal with tasks like cleaning crude oils or making fuels from scrap. But current jobs run into hard spots such as power needs, gear breakdown, and slow work. If you manage a place that handles oil distillation, you see how these troubles can cut speed and raise prices. This piece looks at usual problems with distillation columns and internals. It shares simple ways to fix them, with a main look at oil distillation systems. We will check how fresh ideas can make your gear run easy and tough.

Distillation columns form the core of dividing mixes in oil fields. They heat liquids to make steam, then cool that steam to grab clean parts. In oil distillation, this turns raw or reused oils into handy fuels like gas and diesel.

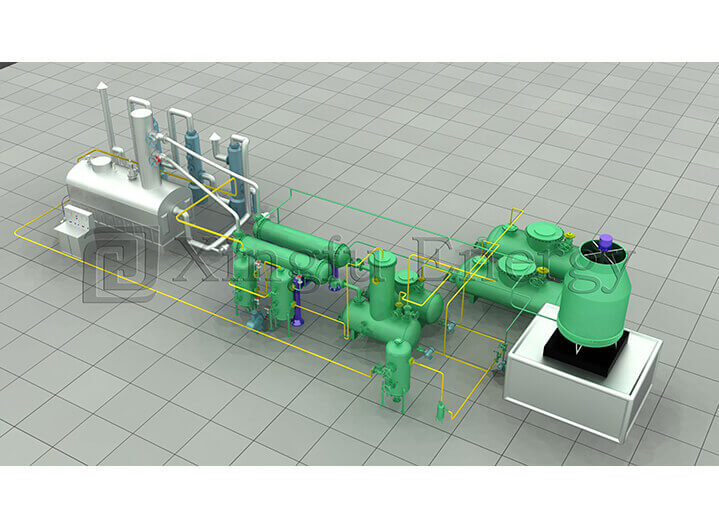

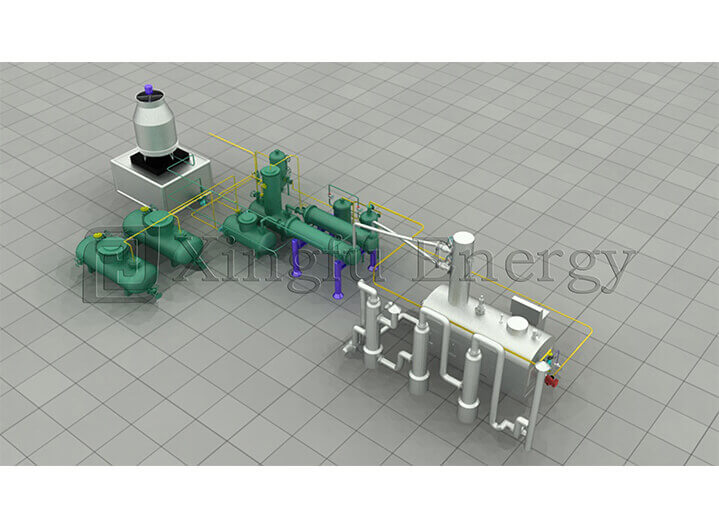

Picture a normal oil distillation setup. Raw oil goes in the column. It gets hot, and vapors climb up through plates or filling stuff. These internals mix steam and liquids for good splitting. The aim? Clean oil goods with little trash. But actual runs don’t always go right. Steam can cool quick, or liquids might not blend well. This leads to bad results.

In oil distillation from waste, like from breaking down tires or plastics, things get harder. You begin with mixed oils that have dirt. So, columns must deal with different inputs without jamming or wasting heat.

Plates are flat spots inside the column where liquids gather and steam bubbles up. Fillings are set or random items that add surface for touch between parts.

Picking the right internals counts a lot. Bad choices can cause jams or uneven moves, dropping your work.

Oil distillation columns face rough settings every day. Hot temps, eating-away stuff, and steady flow push gear to the edge. Let’s split the key issues that plant runners meet.

Dirt buildup occurs when leftovers stick to internals and block ways. In oil distillation, this comes from heavy dirt in the input, like in waste oils. Steam turns to drops that cover surfaces. Or reactions make sticky extras.

Why care? Dirty internals cut touch space, making splitting less good. Your column may need often cleans, which means stop time and more money. In bad cases, it can force full stops, hitting the whole place.

Shakes from pumps or uneven loads can rock columns, loosening bits. Over days, plates might move, or fillings could snap. In oil setups with strong flows, this wear goes fast.

Think of this: A tiny split in a plate lets liquid drip down, blending parts that should stay apart. Outcome? Dirty goods that miss rules. Steady looks help, but spotting troubles early isn’t simple.

Low steam move can drop inside pressure, causing “leak” where liquid falls through plate holes instead of staying. This ruins clean levels. On the other side, too much speed brings foam, where bubbles grow and carry liquid up, cutting work.

In oil distillation, foam is big with gas-filled inputs. If plates are too near, foam from one spot mixes with the next, spoiling split.

Distillation takes lots of power—think warming huge oil amounts. Bad internals mean more heat for the same split, pushing up costs. With higher fuel prices, this hurts.

Nice part: Steps forward in column build help fight these issues. By changing internals, you can lift work without a full fix.

Changing old plates to new kinds can cut power use and raise space. For oil distillation, good fillings mix sizes for better move—small for tight splits, big for taking volume.

This mix works well in old changes, where room is small. It holds pressure even and lifts throughput. It’s great for places handling waste oils.

For hard inputs, pick dirt-fight plates or grid fillings. These have smooth faces that drop buildup. Holes in plates can change to flows, stopping clogs.

In oil systems with eating stuff, strong mixes last longer. Less dirt means fewer halts, keeping work steady.

Oil distillation often has acids or high heats. Columns from tough stuff fight eating, stretching life. For temps over 300°F, heat-steady internals stop breaks.

Set fillings in strong glasses or metals match the column’s make, skipping weak places. They’re not holey, cutting wear unlike old clay.

Each place has its own ways. Made internals spread work ranges, handling mixed oil inputs. Blend traits like better spreaders to manage solids or foam.

This bend lets you fit to changing inputs, like moving from tire oils to plastic ones, without large shifts.

Want to see these fixes work? Check world setups where changed columns handle waste oils well.

In Europe, places use ongoing systems for tire oils, with internals that clean gas and stop dirt. Outcomes? Even runs and high gets.

In Asia, half-ongoing setups in shops manage mixed wastes. They use power and gas cleans for pure outs.

These tales show how right internals turn hard spots into easy jobs.

Changed columns mean less power waste, fewer breaks, and cleaner goods. For oil distillation folks, this makes trust, cutting costs and lifting out.

It also aids meet green rules, turning scrap to fuel without bad smoke.

As a top giver of oil distillation systems, Qingdao Xingfu Energy Equipment Co.,Ltd brings long know-how to the spot. Started in 2010 in Qingdao, China, the group looks at planning and making gear for work needs, like pressure holders and scrap units. With a solid bunch of builders and hand workers, they cover over 70,000 square meters. They hold main papers like CE and ISO9001. Their systems reached over 30 lands, getting good words for make and run. If you seek sure oil distillation ways, they give the skill to face current hard spots straight.

Facing current job hard spots in oil distillation isn’t a never-end fight. By knowing usual issues like dirt, gear wear, and power loss, and using smart fixes through better internals, you can keep your columns doing top. These moves not only drop costs but also make a tougher, more sure job. At last, putting in good distillation tech gives back in easier runs and better ends.

Oil distillation meets troubles like dirt from dirt bits, shakes causing wear, and pressure falls that hit splitting. These can bring stop time and lower gets, but new builds help with tough stuff and better flow holds.

They lift touch between steam and liquids, leading to purer fuels. Changed fillings and plates cut power use and deal with hard inputs, making the full job more sure for today’s wants.

Dirt jams internals, dropping run. Dirt-fight plates and fillings drop buildup, keeping moves even and stretching gear life in rough oil spots.

Yes, fit setups spread ranges for mixed oils, handling foam or solids. This bend meets special place wants, lifting out without big changes.