Hey there! If you run a pyrolysis plant, you likely know the routine well—turning junk like old tires or plastics into handy stuff. But what about that raw oil from pyrolysis? That’s where it gets exciting. Adding a refining distillation plant to your setup isn’t just a basic tweak; it’s like giving your operations a big push. It turns the raw oil into top-notch fuel that’s easier to move and brings in more cash. In this piece, we’ll look closely at how linking these systems can lift your pyrolysis business higher, with real perks and easy examples. Stick around, and you’ll understand why this pair is key for folks in recycling and energy fields.

Pyrolysis is a smart way to heat waste without air. It breaks down the stuff into oil, gas, and char. Picture a busy recycling lot stacked with old tires. Your pyrolysis reactor works non-stop. It changes those tires into raw oil that makes up around 40%-50% of the weight. It’s a good deal: it cuts down on trash in dumps and makes energy from garbage. But there’s a snag—what about the oil right from the reactor? It’s usually dark, thick, and full of junk like sulfur and heavy metals. That oil isn’t great; it’s tough to use in motors or factory work.

That’s why the refining distillation plant steps in—it’s the ideal match to remove those impurities. It heats the raw oil in a controlled way. Then, it splits out lighter parts like gasoline and diesel. No more dealing with cheap heavy fuel; your final goods meet what the market wants. For instance, in a standard setup, you might begin with oil from tires that’s only fit for simple heating. After distillation, you end up with clear, strong diesel good for trucks or generators. This link-up keeps your whole operation smooth. It turns possible problems into steady income.

So, how does this play out for real? Let’s go through it step by step, like you’re right there in the plant.

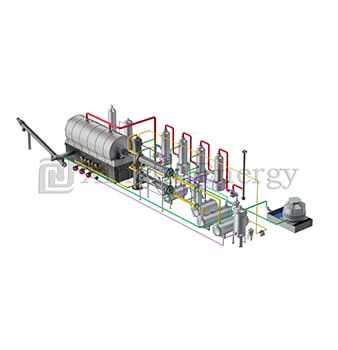

First, the raw oil from the pyrolysis unit gets dried fast to get rid of all water. Next, it goes into the reactor. Here, the heating setup starts up—it uses flowing hot air instead of an open fire. Why? It stops hot spots on the gear. That prevents breaks over time and keeps things safer. Temps climb to about 650°C, but it all runs at regular pressure. This lowers the chance of blasts.

As the raw oil warms up, it turns to vapor. The vapors go up through a catalytic tower. There, special catalysts—set for fuel oil—help split molecules. Gasoline vapors come out the top. They cool in the condenser and gather in tanks. Diesel comes from side spots. What about leftover burnable gases? They get cleaned in exhaust gear. Then, they’re sent back to the furnace as fuel. Pretty neat, huh? Nothing gets wasted.

The results on the other side are solid. For a 10-ton batch, you can get gasoline at 15%-20%, diesel at 70%-75%, small gases at 2%-5%, and leftover at 10%-18%. Total oil output reaches 90%. That means nearly everything becomes useful. And the quality? Diesel passes through a final mix tank to turn into good fuel oil—clean and dependable.

Think about this: A little pyrolysis plant in Southeast Asia handles 10 tons of waste plastics each day. Their raw oil sells cheap nearby. But after adding a distillation unit, they refine it into diesel that meets emission rules. This opens up sales abroad. All at once, earnings rise 30% because folks pay extra for the better stuff.

Adding a refining distillation plant isn’t about fancy extras—it’s about piling up gains. Here’s why it works so well.

For a clear view, check this quick table comparing two usual plant sizes:

| Feature | 10-Ton Refining Distillation Plant | 20-Ton Refining Distillation Plant |

| Daily Capacity | 10 Tons | 20 Tons |

| Footprint | 19m × 3.6m | 19m × 4m |

| Power Consumption | 15 kW/Hour | 20 kW/Hour |

| Fuel Per Batch | 250 kg | 300 kg |

| Suitable For | Small to Medium Businesses | Large Industrial Setups |

This layout lets you grow your business without a total redo.

Sure, linking systems sounds easy, but what bumps might you hit? Space is one—these plants need around 6000 mm of height room, so map out your spot early. Another is the quality of what you feed in; uneven pyrolysis oil could block catalysts. How to fix it? Test often and tweak as needed.

From talks in the field, I heard about a recycler in Europe who added a distillation unit but ran into trouble with mixed tire oils. They solved it by putting in a pre-filter. That pushed run time up to 95%. Info from like setups shows linking can cut process time by 15%. So, you can deal with more waste without added hours.

Let’s check out some true cases. Imagine a medium pyrolysis outfit in Indonesia dealing with loads of waste tires. Their solo system made oil that was hard to sell because of dirt. After hooking up a distillation unit, it shifted—they now make diesel for local trucks, with 90% oil output. Income jumped, fumes went down, and they got green stamps. That drew in buyers who care about the planet.

Or consider a U.S. firm zeroed in on plastics. After the add-on, their refined goods run on-site machines, dropping power bills by 25%. These aren’t made-up tales; they’re trends seen over years in the biz, with firms noting 20%-40% better runs. The secret is making side stuff into main stars.

Size counts here. If you’re new or short on room, pick the 10-ton version—6.6 meters long, it takes 10 tons easy. For larger goals, the 20-ton one doubles the load with not much more space.

Seek plants with auto welding for strength and X-ray checks to spot no flaws. Fuel options—like oil, gas, or LPG—let you fit local stuff. And remember the catalysts; they’re vital for high oil amounts.

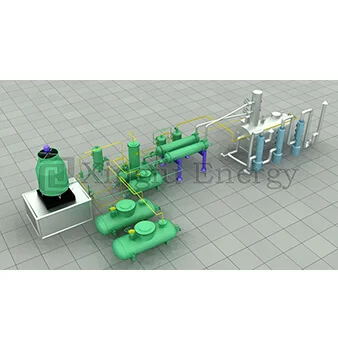

When it comes to solid gear, Qingdao Xingfu Energy shines. Started in 2010 and based in Shandong, it has grown into a tech-savvy leader with over 200 staff and a huge 70,500 square meter shop. Their R&D is tough, with many engineers honing pyrolysis and distillation tools. Their plants, like the XFZL series, have sturdy builds with CE and ISO nods, meeting world rules.

What makes them special? They’ve shipped to over 30 lands, from Asia to Europe, getting great feedback for tough, quick systems. If you want a 10-ton or 20-ton, Xingfu Energy gives safe, high-output, simple-to-link gear. They’re not just vendors; they’re allies pushing your pyrolysis work ahead.

To wrap up, hooking a refining distillation plant to your pyrolysis setup is a wise step. It ramps up how well things run, lifts product grade, and betters your earnings. From safer work to bigger market worth, the upsides stand out. If you’re in waste-to-energy, this team-up might be the lift you want for wins. Set to step up? It’s smart to check how these fit your flow.

What are the benefits of integrating systems like refining distillation plants into my pyrolysis business?

Linking systems can change your raw pyrolysis oil into fine fuels like diesel and gasoline. This ups the quality of what you sell and boosts cash flow. For example, you could hit oil outputs up to 90%. That makes your outfit more in the game without big changes.

Why is a refining distillation plant a great addition to pyrolysis operations?

It refines raw goods right away and handles stuff like tire or plastic oil without hassle. This leads to purer items, less trash, and reused gases for heat—cutting costs while keeping green.

Can a small refining distillation plant meet growing pyrolysis demands?

Yes. The 10-ton type covers mid-level needs, with space to bump to 20 tons as you get bigger. The main thing is lining up size with your daily waste for easy linking.

What safety features should I look for in a refining distillation plant to complement my pyrolysis business?

Go for plants with hot air flow for indirect heat and regular pressure runs. These cut risks a lot, make gear last longer, and keep your crew safer day to day.

How do I start integrating a refining distillation plant into my system?

Look at your current pyrolysis output first. Then, choose a plant that fits your work. Suppliers like Xingfu Energy give custom tips to make sure the link boosts your full run from the start.