Tyre pyrolysis gives a good answer for handling old tyres. It changes them into useful outputs like pyrolysis oil, carbon black, steel wire, and gases that can burn. These materials can go back into factory work. This cuts down on trash and helps a circular economy. This article looks at the main outputs from tyre pyrolysis. It covers their uses and how new tech—like systems from Qingdao Xingfu Energy—boosts efficiency and green operation.

Tyre pyrolysis is a heat-driven process. It breaks up old tyres without using oxygen. This action makes valuable outputs. The main outputs include pyrolysis oil, carbon black residue, steel wire, and gases that don’t turn to liquid. Each material has special traits. These traits decide how industries can use them sustainably.

Pyrolysis oil is a major output. It makes up about 40–45% of the total yield. This oil can power diesel motors, especially those needing high power at low speeds. It also works well in heating furnaces and industrial setups. The oil has a strong heat value of 38,275 kJ/kg. Its density is 0.9072 mg/cm³ when measured at 20°C. Other key points are a flash point of 47°C and a pour point of -21°C. This energy level is like regular diesel fuel.

Carbon black residue comes next. It forms roughly 32–36% of the output. This powder gets processed. First, it is moistened and mixed. Then it gets shaped into grains. Finally, it dries. This creates even carbon black particles sized 10-100 μm. Later, it can be refined more. Granulation makes particles between 0.7–2.0 mm. This size is good for reuse. It fits rubber mixing or plastic making.

Tyres hold steel wires inside. These wires get pulled apart during pyrolysis. They add about 14–16% to the total yield. The pulled-out steel wire has high recycling value. Metal recycling places want this material. Why? It has iron that can be recovered. This lets it go into new steel items.

Gases that don’t turn to liquid make up around 5–8% of the yield. These gases usually hold lots of hydrocarbons. Methane and ethylene are common. This makes them very easy to burn. They can fuel the pyrolysis plant itself. Or, they can run power generators. This supports sustainable running.

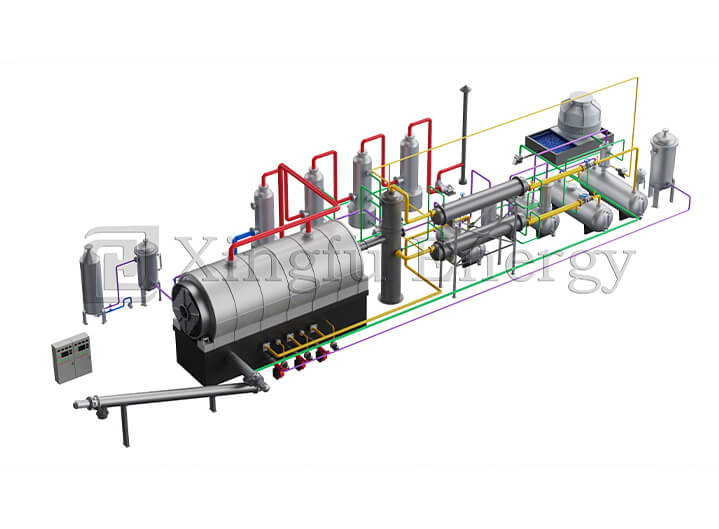

Qingdao Xingfu Energy‘s complete tyre pyrolysis plant uses multi-stage cooling loops. This pulls out more fuel oil. It also makes sure recovery rates stay high for all outputs. Safety gets handled too. Features like pulse dust removal help. So do sealed systems for taking out slag.

Pyrolysis oil has huge promise. It works as a different energy source when refined or treated.

To make it more useful, the oil goes through distillation. This step makes lighter fuel parts. Results can match diesel or gasoline. The oil distillation plant creates several things. Petrol comes out (15-20%). Gasoline-range products are about 70-75%. Flammable gas makes 2-5%. Residue is left (10-18%). This lets it fit into current fuel setups. Little change is needed. It also lowers the need for fuels from fossils.

Or, pyrolysis oil can be a start point. It makes chemicals like aromatic compounds. Ways to do this include catalytic cracking. Hydrodeoxygenation is another method. These chemicals matter a lot. Factories use them for paints, glues, and plastics.

Qingdao Xingfu Energy’s distillation units secure high recovery. They use modern separation tech. This lets users change raw oil into high-value goods fast.

Recovered carbon black (rCB) has many paths back into making things. Its strengthening nature helps.

rCB is often put back into rubber. Tyres, conveyor belts, or shoe soles use it. It acts much like bought carbon black. Thermoplastics use it too. There, it gives colour and fights UV damage.

Better processing can lift rCB’s power. Surface tweaks are one way. This boosts how well it works with plastics or mixes. These mixes go into car parts or electronic cases. Granulated rCB also handles easier. It spreads better when mixing.

Qingdao Xingfu Energy’s carbon black granulation system stops leaks. It cuts dust pollution. Production runs non-stop. This makes it a top pick for turning rCB into value greenly.

Getting steel from tyres cuts waste. It also backs circular economy aims in metal work.

Machines pull the steel apart. Magnetic sorting helps too. This isolates steel wires well from leftover carbon. It happens after pyrolysis. This step lifts purity. Smelting needs high purity.

The recovered steel can feed furnaces directly. Electric arc or induction types work. Only light prep is needed. Cleaning or resizing might happen first. It lessens the need for new iron ore. It also saves energy in making new steel.

Qingdao Xingfu Energy’s setups allow effective steel pulling. They use sealed, hot slag removal. This lowers dirt risks during pulling.

Using the non-liquid gases well helps plants run on their own power.

These gases often burn in special burners. Or they heat boilers. This heat goes back to the reactor. This slashes outside fuel needs a lot.

When put into CHP systems, the gases give two things. They offer heat and make electricity. This suits energy setups in industrial areas. Remote spots gain too.

Qingdao Xingfu Energy’s hot air heating system has a special heat reuse plan. This shows how syn gas use lifts work speed. It also cuts harm to nature.

Green use plans help nature goals. This works near and far.

Changing waste tyres into usable stuff keeps them out of dumps. In dumps, they can start fires. They also leak bad chemicals slowly.

Swapping fossil fuels for pyrolytic ones cuts pollution. This pollution links to transport fuels or factory heat. So it backs climate aims.

Following rules on output handling is key. Dust-free discharge tools help. This meets laws. It also keeps people safer.

Qingdao Xingfu Energy’s gear works sealed. No dust gets out. This backs their promise to green work at all steps.

As a top maker focused on pyrolysis plants and distilling gear,

Qingdao Xingfu Energy Equipment Co., Ltd makes full automatic waste tyre pyrolysis plants. They also build support systems. Distillation units and carbon black granulators are examples. These are made for full resource recovery.

Their plans have multi-step cooling loops. Sealed slag removal is included. Safety uses submerged arc welding. The goal? Top yield quality plus safe running across all change steps.

New ideas like heat reuse systems help. So do electronic pack lines for rCB. Pulse dust removal tech is key. Qingdao Xingfu leads in joining factory speed with earth care. This matches today’s green push.

Tyre pyrolysis turns waste trouble into chances. It shifts thrown-out tyres into key resources. Fuel oils, carbon black bits, reusable steel wires, and burnable syngas are outputs. Qingdao Xingfu Energy shows how tech newness helps green use for every stream. It lifts money returns while dropping earth loads.

The net heat number is 38,275 KJ/kg (bomb method). This makes it like regular diesel used in factories.

Recovered carbon black can partly swap for store-bought kinds. How much depends on the job. More steps like granulation boost fit. This is true for rubber mixing areas.

Basic filtering might be enough, based on what’s in them. Yet, deeper cleaning could be needed sometimes. This is vital for touchy burn systems like CHP units or turbines.