Plastic waste is a big problem everywhere. Tons of plastic end up in landfills and oceans every year. This hurts animals, plants, and nature. It messes up homes for fish and birds. Plus, plastic pollution stays around for hundreds of years. This makes the earth dirtier. We need smart ways to fix this fast. Good recycling can help keep our planet safe.

Old recycling ways don’t always work great. Many systems can’t handle plastics that are mixed up or dirty. So, lots of plastic gets thrown out. Also, these methods need a bunch of energy. They can even make new pollution. These troubles show we need better ideas. A plastic pyrolysis machine is one new way to make recycling easier and cleaner.

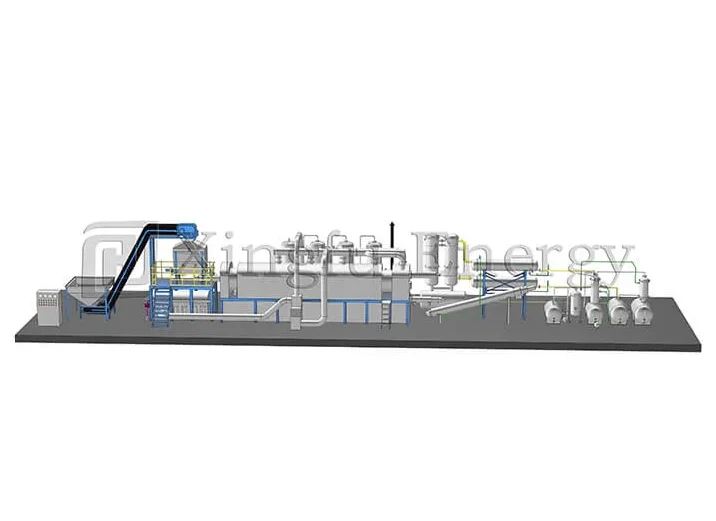

A plastic pyrolysis machine is a neat tool for recycling. It turns old plastics into useful things like fuel oil, carbon black, and syngas. It works by heating plastics without oxygen. Unlike old recycling, it doesn’t need plastics sorted by color or type. This makes it awesome for all kinds of plastic waste. It cuts down on trash and gets good stuff from plastics that are hard to recycle.

The plastic pyrolysis process steps have a few main parts:

Feeding: Workers put waste plastics into a reactor. It gets super hot inside.

Thermal Decomposition: At 300°C to 700°C, plastics break into tiny bits called hydrocarbons.

Condensation: Hot gases cool off. They turn into liquid fuel oil.

Separation: Other stuff, like carbon black and syngas, gets pulled out for later use.

The fully automatic plastic pyrolysis plant from Qingdao Xingfu Energy Equipment Co., Ltd., makes up to 85% fuel oil. It also gets carbon black (10-30%) and syngas (5-10%).

Using a plastic pyrolysis machine is great for many reasons:

Less Trash: It shrinks the piles of plastic going to landfills.

New Products: It turns tough plastics into fuel oil and other cool things.

Saves Power: The syngas it makes can heat the machine. This uses less outside energy.

Helps Nature: It makes way less pollution than burning plastics.

A plastic pyrolysis machine heats plastics in a special no-oxygen space. This stops them from catching fire. The reactor breaks plastics into things like liquid fuel oil and solid carbon black. Fancy models from Qingdao Xingfu Energy Equipment Co., Ltd., have extra tools. They use multi-level cooling and tight feeding systems. These help the machine work faster and better.

Plastic pyrolysis machines are awesome because:

Super Fast: They run on their own. This means less work for people and more results.

Takes All Plastics: They can handle mixed or messy plastics without lots of sorting.

Good for Earth: They make stuff that can be used again, like fuel or factory materials.

Saves Cash: They cut the need for new oil by reusing plastic waste.

When picking a plastic pyrolysis machine, think about these:

How Much It Holds: Make sure it can take the amount of plastic you need to process.

How Automatic It Is: Machines that run themselves save time and money.

Safety Stuff: Look for things like pressure valves and heat checks to keep it safe.

Planet Rules: Pick machines that control pollution to follow laws.

Qingdao Xingfu Energy Equipment Co., Ltd., at No.31th Longcheng Road, Shibei District Qingdao China, makes machines you can tweak for your needs.

The best way to cut plastic waste is to use less from the start. People can switch to materials that break down naturally. Reusable bags and bottles are a big help. Governments can make rules to stop single-use plastics. Companies can design products that are easy to recycle or compost. Teaching folks about using less plastic and throwing it away right makes a big difference.

New tech is making recycling way better. Smart machines with artificial intelligence (AI) can sort plastics super well. They know exactly what kind each plastic is. Robots help by doing the sorting fast with no mistakes. Also, chemical recycling, like depolymerization, breaks plastics into their starting pieces. This makes super good recycled materials. These tools speed up recycling and make it work better.

Getting everyone to recycle is really important. Schools and towns can teach kids and grown-ups about recycling. Putting recycling bins where people can easily use them helps a lot. Holding events to collect plastics gets people excited. Governments and groups can give out rewards, like gift cards, to make recycling fun and worth it.

The plastic pyrolysis machine is a great answer for plastics that are hard to recycle. To use it in big factories, we need bigger reactors. These can handle more trash at once. The fully automatic plastic pyrolysis plant from Qingdao Xingfu Energy Equipment Co., Ltd., gets up to 85% fuel oil. It also pulls out carbon black (10-30%) and syngas (5-10%). These upgrades make it cheaper and better for huge projects.

Using plastic pyrolysis machines all over has big wins. For money, it makes new ways to earn by turning trash into fuel oil and carbon black. For the planet, it means less trash in landfills. It also cuts down on bad gases compared to burning plastics. Adding pyrolysis to waste systems helps make a circular economy. This turns old stuff into new resources.

Plastic pyrolysis heats waste plastics to make fuel oil, carbon black, and syngas. It doesn’t burn them.

It lowers landfill trash and gets useful things from hard-to-recycle plastics. It also makes less pollution than burning.

Most plastics work fine. But some extras or dirt might make it a bit harder.

Yes! It cuts bad emissions compared to burning. It also reuses waste as new stuff.

Reach out to Qingdao Xingfu Energy Equipment Co., Ltd., at No.31th Longcheng Road, Shibei District Qingdao China. They’ve been pros in industrial boilers and pyrolysis systems since 2010.