Planning a new setup in the waste oil recycling world? One of the first headaches is figuring out how much room you’ll actually need. Nobody wants to sign on for equipment only to realize it won’t fit in the shop or requires a massive overhaul of the building. That’s why getting the installation details right upfront matters so much. For a 10T Oil Distillation Plant, the space requirements are surprisingly manageable—making it a solid choice for mid-sized operations looking to refine pyrolysis oil without turning the whole facility upside down. Let’s break down the key parameters, from footprint to height, so you can picture exactly how this fits into your space.

Think about it. You’ve got raw oil from tyres or plastics piling up, and you need to turn it into sellable fuel fast. A distillation plant like this one processes 10 tons a day, hitting high yields while running smoothly. But if the layout doesn’t work, delays stack up—permits, construction, you name it. I’ve seen shops lose weeks because they underestimated the height for cranes or forgot about clearance for pipes.

Good planning keeps things moving. With clear specs on floor space and highest points, you can map out the foundation, ventilation, and access roads early. This 10T model keeps things compact compared to bigger rigs, yet it delivers on output. Operators often say the straightforward setup is what sold them—less downtime getting started, more time making product.

Folks new to this sometimes run into snags like:

The key? Know the numbers cold. For this plant, everything’s designed with real-world shops in mind—no exotic requirements that jack up costs.

Here’s where the rubber meets the road. The 10T Oil Distillation Plant comes with precise dimensions that make planning straightforward.

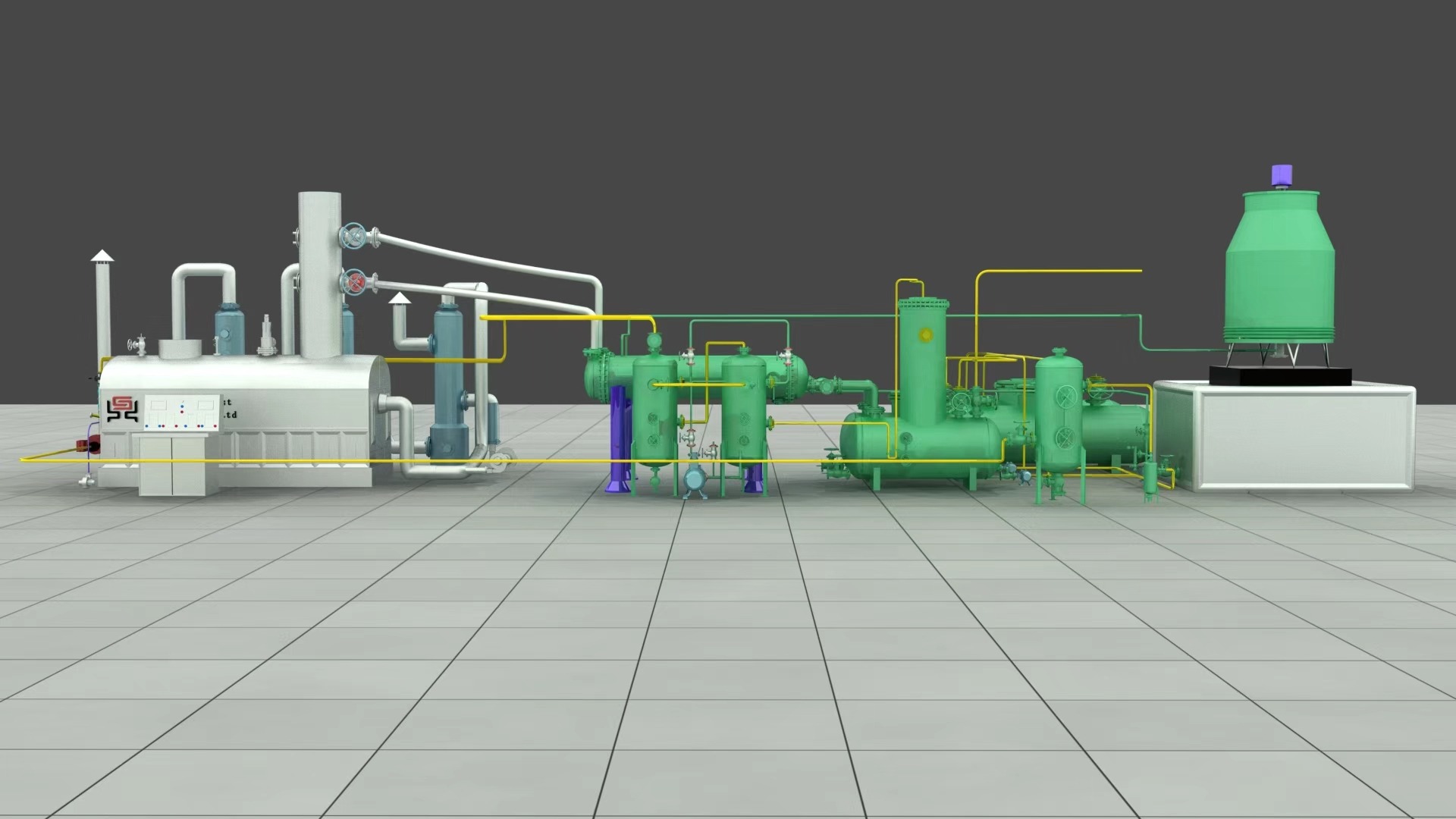

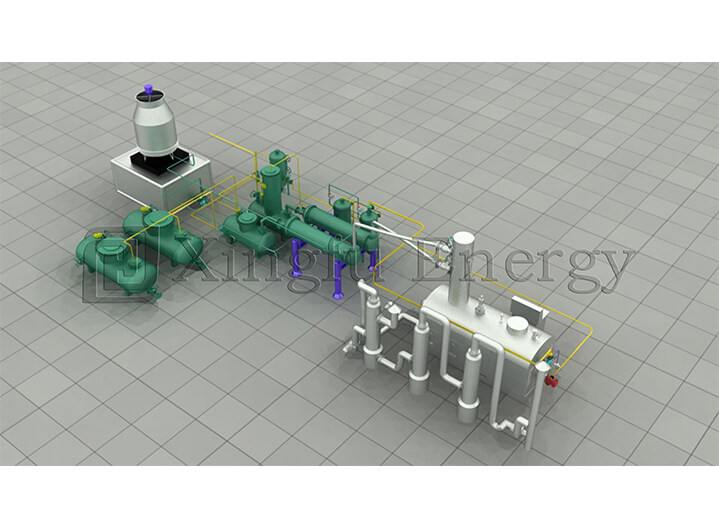

The main unit itself isn’t a monster. It measures 6600 mm long, 2500 mm wide, and 2850 mm high. That’s about the size of a large shipping container turned on its side—easy to truck in and position.

But the real question is the total floor space. You’ll need an area of 19,000 mm by 3,600 mm. Break that down: roughly 62 feet long by 12 feet wide. Plenty of room for the reactor, catalytic tower, condensers, and storage tanks, plus space to move around.

Why this layout? It allows for a linear flow—raw oil in one end, clean petrol and diesel out the other. In one setup I heard about in Asia, they slotted it into an existing warehouse bay with minimal mods, just pouring a new concrete pad.

This is the one that catches people off guard. The installation’s highest point hits 6000 mm—that’s about 20 feet. Why so tall? The catalytic tower and exhaust stack need that clearance for proper gas flow and safety.

In practice, that means your building should have at least 22-25 feet of clear height to allow for lifting during install and future maintenance. If you’re in a lower-roof shop, no panic—many add a simple extension or go outdoor under a canopy. One operator in a tight urban spot built a dedicated shed just for the tower section. Worked like a charm, kept the rest of the plant indoors.

To make it easy, here’s a table pulling together the essentials. These come straight from proven builds, with a note that minor tweaks might happen for site-specific designs.

| Parameter | Details |

| Main Equipment Size | 6600 mm (L) × 2500 mm (W) × 2850 mm (H) |

| Total Floor Space | 19,000 mm × 3,600 mm |

| Highest Installation Point | 6000 mm |

| Power Consumption | 15 kW/h |

| Total Power | 36 kW |

| Heating Method | Circulating hot air |

| Working Pressure | Normal pressure |

These specs keep utilities in check too—low power draw means standard electrical hookups in most industrial zones.

Picture a typical recycling yard. You’ve got pyrolysis units out back, churning out crude oil. Pipe that over to the 10T distillation plant tucked in a corner bay. With that 19m x 3.6m footprint, it slots in without eating the whole floor.

In a project from Southeast Asia, a team installed one alongside existing tanks. They laid a reinforced slab, ran gas lines for heating, and were up in under a month. The 6m height? Handled with a basic overhead crane—no need for fancy scaffolding.

Another example: a European site with height restrictions. They oriented the plant lengthwise along the building’s ridge, venting straight up. Clearance was tight, but the specs gave them confidence it would work. Result? Smooth startup, processing waste oil into fuel without a hitch.

These stories show why upfront details pay off. You avoid surprises, budget accurately, and get producing sooner.

Beyond space, think about foundations. The plant needs a level concrete base to handle vibrations—standard for this weight class.

Operators appreciate the hot air heating here. No direct flames on the reactor means less wear, and it fits standard fire codes easier.

A quick word on the company behind this gear. Qingdao Xingfu Energy, started in 2010 in Shandong Province, China, builds industrial boilers, pressure vessels, and waste tyre & plastic pyrolysis systems. With over 228 employees—including dozens of engineers and certified welders—they run a big facility churning out reliable equipment. Exports go to more than 30 countries, from Asia to Europe, backed by certifications like CE and ISO9001.

Bottom line, the 10T Oil Distillation Plant strikes a great balance—compact enough for most shops, yet capable of serious daily output. Nail the space planning with those key params like the 19,000 mm x 3,600 mm footprint and 6000 mm height, and you’re set for a hassle-free install. It’s the kind of practical design that gets you refining waste oil profitably, without the headaches of oversized gear.

You’ll need about 19,000 mm by 3,600 mm total. That covers the equipment, tanks, and room to work around it comfortably.

It reaches 6000 mm. Plan for at least that much clear height in your building, plus some extra for cranes.

The core equipment measures 6600 mm long, 2500 mm wide, and 2850 mm high—fits nicely into standard industrial bays.

A level concrete slab works fine. The footprint is designed for typical loads, no exotic reinforcements needed in most cases.

With good prep, many sites are operational in a few weeks to a month, thanks to the straightforward layout.