Inconsistent oil quality is a big challenge. It directly affects if the product sells and the process profits. Knowing the root causes helps operators fix the problems. This leads to better product consistency.

Different feedstocks are the main reason oil quality changes. Waste materials vary widely. These include plastic types and plant sources. They hold different amounts of sulfur, nitrogen, and aromatic parts. These differences show up in the final distilled product. If processors handle mixed feedstocks without sorting and checking first, the resulting oil changes unpredictably. Its thickness, color, and chemical nature shift. Setting strict rules for sorting feedstocks helps. Keeping raw materials steady solves this basic issue.

Temperature changes during separation cause inconsistent results. This leads to mixing between different oil parts. Precise temperature control at each step ensures molecules separate well. It keeps the product within specs. Operators must keep tight temperature limits. Staying within ±5°C of targets throughout the column is vital. Modern control systems with linked temperature controllers provide the needed precision. They fix temperature-related quality problems.

Dirt like water, tiny particles, and leftover catalysts greatly harms oil quality and stability. Water content over 0.5% causes mixing problems and shortens shelf life. Tiny particles create filtering troubles. They harm fuel systems in engines. Putting in good pre-treatment systems fixes this. These include water removal units and multi-step filters. They take out these impurities before distillation starts.

Equipment fouling is a constant problem. It cuts efficiency and raises repair costs. Active prevention plans keep performance best and make equipment last longer.

Heat exchanger surfaces, column parts, and condenser tubes get dirty. This happens from sticking-together reactions, coke making, and mineral build-up. High heat speeds up these problems. This is worse with unstable compounds and tiny metals. Finding fouling starters through regular oil checks helps. It allows smart maintenance planning and focused prevention steps.

Regular cleaning cycles using proper solvents and tools keep equipment working well. Chemical cleaning with special de-coking agents removes carbon build-up. Mechanical cleaning tackles harder scale. Using cleaning-in-place (CIP) systems cuts downtime. It ensures thorough cleaning of tricky shapes. Regular checks using safe testing methods spot early fouling signs. This happens before performance drops.

Anti-fouling additives help. These include antioxidants and metal stoppers. They reduce sticking-together and deposit forming. Pre-treatment steps like clay treatment remove fouling starters from the feed. Picking the right additives based on oil make-up and running conditions is key. This makes them work best while keeping product quality.

Steady pressure is vital for good separation and product quality. Knowing why pressure jumps happen helps put in good fixes.

Pressure changes come from many places. These include shifting vapor flow, changing liquid levels, and control system issues. Not enough space for vapor to separate causes carry-over problems. This sends pressure troubles through the column. Poor reflux control systems add to pressure jumps. They create loops between temperature and pressure controls.

Vacuum system problems hit low-pressure distillation hard. Too-small vacuum pumps fight to keep steady pressure when loads change. Air leaks through seals and joints bring in gases that won’t condense. These mess up vacuum levels. Right vacuum system sizing and regular leak checks fix these operation issues.

Smart pressure control strategies help. These include linked control loops. They keep running conditions stable. Adding good vapor-liquid separation sections cuts carry-over pressure jumps. Regular checks of pressure tools ensure accurate control. They stop drift-related problems. Adding pressure surge guards protects equipment. This is important during start-up and upsets.

Getting the most product impacts profits and resource use. Finding efficiency blocks allows focused improvements. This boosts product recovery rates.

Heat leaks through bad insulation cut energy for boiling and separation. Fouled heat exchangers need more energy but move heat poorly. Putting in full energy saving plans helps a lot. These include heat recovery networks. Regular heat pictures find heat loss spots needing repair.

Column design flaws hurt separation. Not enough stages and wrong internal parts limit efficiency. Too little reflux harms product purity and recovery. Tray or packing choice must fit the specific separation needs and running conditions. Column flow limits cut how much you can process. They harm separation when running full.

Process improvement needs careful look at running factors. This finds chances to do better. Modern computer tools test different running situations and equipment setups. Live improvement systems keep adjusting running factors. They hold top performance as conditions shift. Tracking methods find trends and changes affecting yield.

Safety is crucial in hot distillation. Full risk checks and safety plans are needed. Strong safety systems protect people and gear. They keep the operation running.

Hot distillation is naturally risky. Processing oil parts needs extreme conditions. Dangers include fire and explosion chances, harmful gases, and broken equipment. These need strong steps to protect people, property, and nature.

Oil vapors create big fire and explosion risks everywhere in distillation. Hot surfaces above ignition points can start fires if vapor leaks out. Proper vapor alarms and fire fighting systems give key protection. Safe hot work rules and area grouping cut ignition chances during repairs.

Pyrolysis oils hold many bad compounds. These risk health through breathing or skin contact. Vapor leaks from gear expose workers. Full leak check and repair (LDAR) programs reduce stray emissions. Safety gear needs must match the specific dangers. These dangers link to different oil parts and running conditions.

Continuous watch systems warn early of danger. Gas detectors look for oil vapors and harmful gases everywhere. Temperature and pressure monitors spot bad running conditions. These could lead to gear failure. Linking watch systems to emergency stops gives automatic protection from bad situations.

Full training ensures workers know the dangers and safety steps for oil distillation. Emergency plans must cover many events. These include fires, spills, and gear failures. Regular safety drills keep workers ready for emergencies. Process safety systems give organized ways to spot and control process dangers.

Xingfu Energy is a top provider of modern oil distillation answers. They focus on processing pyrolysis oil from many waste types.

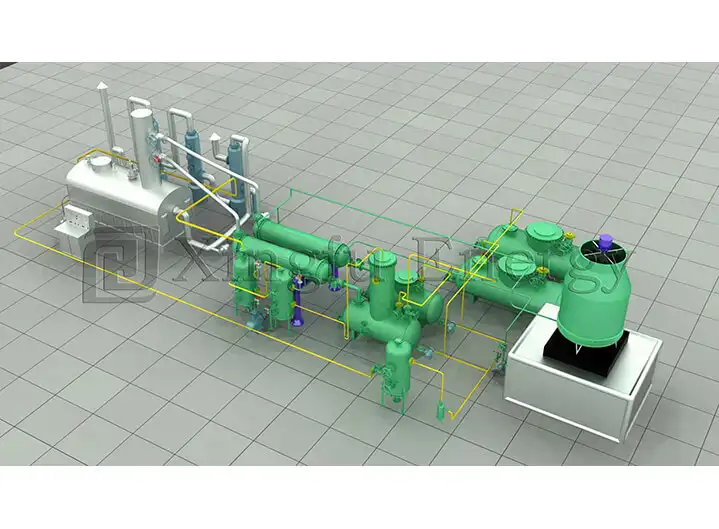

Xingfu Energy leads in new oil distillation answers made for pyrolysis oil. They deeply understand the special challenges of waste-derived oil. This lets them build custom gear and process fixes. Their know-how covers both old distillation ideas and new separation tech. This tech works for complex oil mixes.

Xingfu Energy’s gear has modular builds, smart controls, and proven global results. They offer scalable, efficient, reliable distillation tech for many pyrolysis jobs.

Xingfu Energy’s modular way lets plants size up or down based on feedstock and market needs. Standard modules cut design costs and build time. They keep options open for future growth. This idea especially helps smaller plants. It lets them join the pyrolysis oil market without huge spending.

Sophisticated control systems link all running factors. They hold best performance as conditions shift. These systems use smart math that sees problems coming. They fix things automatically. Live improvement skills keep tweaking running factors. This gets the most yield and best product quality. It also uses less energy.

Xingfu Energy’s global base shows their tech works well in different places and rule sets. World projects give useful know-how. This tackles local feedstock changes and product needs. This proven record gives confidence to possible clients thinking about buying tech.

Oil distillation from pyrolysis has tough tech problems. Solving them needs organized methods. Success relies on seeing how feedstock quality, process control, gear design, and safety link. Using full fixes for each trouble area ensures reliable running and steady product quality. Top tech suppliers like Xingfu Energy offer joined answers. These tackle challenges through proven gear designs and control systems. Constant betterment through watching, studying, and improving keeps a lead in this changing field.

The best range is usually 150-400°C. It depends on the desired oil parts. Light parts boil off at 150-250°C. Heavier parts need heat up to 400°C. Keeping exact control within ±5°C ensures steady separation. It stops heat harm to sensitive bits.

Regular care should include monthly checks, cleaning every three months, and full service yearly. Clean heat exchangers based on fouling speed. This usually means every 3-6 months. Maintenance based on equipment checks can set the best service times.

Most units handle different oils with the right setting changes. But very different feedstocks might need different pre-treatments and running conditions. Flexible design features let processing of mixed feedstocks. This happens while keeping product quality right.