The pyrolysis field is changing fast. Semi-continuous systems are becoming better than old batch ways. This part shows the main differences between them. We focus on how they are built. We look at how much machines do the work. We compare how well they run. By looking at their shape and how they work, we see why semi-continuous pyrolysis is a big step forward for recycling tires.

Semi-continuous pyrolysis systems are a big jump in tire recycling tech. They are better than old batch ways. In batch pyrolysis, workers must stop the whole system between cycles. They load new tires. They take out products. This makes a start-stop pattern. Each new batch needs heating from room temperature. This uses lots of energy and time.

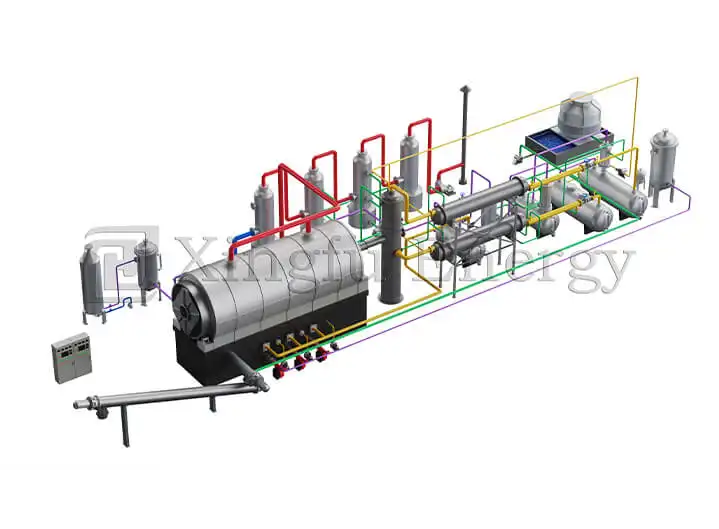

Semi-continuous systems keep heat steady. They let you add old tires all the time. They let you take out products too. The reactor stays hot at its best level. Feeding parts add waste tires. At the same time, other parts take out finished material. This design avoids the heating-cooling cycles of batch work. This leads to steadier conditions. It also saves more energy.

Batch pyrolysis systems usually need lots of worker help each cycle. People must load raw stuff by hand. They must watch heat levels during heating. They must pull out products after cooling. This hands-on way needs more workers. It also makes changes in how things are done.

Semi-continuous systems use smart machine tech. This cuts down on people help. Automatic feeders add tires. Heat is watched all the time. Built-in parts take out products. This lowers worker needs. It also keeps the work steady. The smooth running allows better control. Workers get less tired too.

The heat-cool cycles in batch systems stress the reactor parts. This can make the gear wear out faster. Each heat cycle makes metal parts grow and shrink. This causes tiredness. It means more fixes are needed.

Semi-continuous work keeps heat even. This lowers heat stress. It makes the gear last longer. The steady heat causes less damage from changing temperatures. It also lets you plan fixes when you choose to stop.

Product quality is key to telling these systems apart. Here we see how semi-continuous work makes more even oil, cleaner carbon black, and better steel wire recovery than batch ways. The steady heat of continuous systems makes more uniform products. This is a big plus for sellers and buyers.

Oil steadiness is a big plus for semi-continuous pyrolysis. Batch work creates changing heat each cycle. This causes different product traits from batch to batch. Heat ups and downs during heating and cooling change oil makeup and quality.

Semi-continuous systems keep heat steady. This makes oil traits more alike. The even conditions mean stuff breaks down the same way. The oil that comes out has traits you can count on. This oil works well for mixing into fuel or as a chemical start point.

Carbon black quality needs steady heat and even time in the reactor. Batch systems have heat changes. This can make carbon black with different grain sizes and surfaces. These differences change the sale price and uses for the recovered carbon black.

Semi-continuous work keeps the best heat level going. This makes carbon black with more alike traits. The steady work gives better grain size spread and surface area. This raises the sale price of the recovered carbon black.

Steel wire recovery works better with steady heat. This heat breaks down rubber fully. It also keeps the wire strong. Batch systems may get too hot or not hot enough. This hurts wire recovery quality.

Semi-continuous systems give steady heat. This gets the best wire recovery. The wire stays strong and clean. The even work setting gets the most wire back. The wire stays good too.

Money matters often decide which tech is used for waste work. This look checks the money side of semi-continuous pyrolysis. We see start-up costs. We see running costs. We see how it fits the market. It costs more at first. But continuous systems save money later. They work better. They need fewer workers. They match what buyers want: steady recycled goods.

Semi-continuous systems cost more to buy at first. This is because of smart machine gear and continuous work parts. But, the long-term payback is usually better than batch systems. It runs better and costs less to run.

Better work speed and fewer worker needs make more money per plant size. The improved product quality and steadiness also get higher prices in other markets. This raises total profit.

Batch system running costs include higher worker pay. They use more energy from restarting heat cycles. They need fixes more often. The stop-start way of batch work cuts how much gets done per hour.

Semi-continuous work cuts the cost per ton a lot. It saves energy. It needs fewer workers. It works faster. The steady work also makes less waste. It gets more material back.

Buyers take recovered goods if the quality is steady and supply is reliable. Batch work often cannot meet the steady quality and reliable supply that factory buyers need.

Semi-continuous systems fit buyer needs better. They make steady product quality. They give reliable supply. Keeping steady output and product specs makes these systems more liked by buyers in tire recycling jobs.

Work speed is a key plus of semi-continuous tech. This part tells how continuous tire adding, steady heat, and machine work make recycling smoother. By removing the stop-start way of batch work, these systems do more with less energy and fewer workers.

Semi-continuous systems remove dead time between batch loads and unloads. The feeding parts let stuff move in steadily. Good work conditions stay.

This flow makes much better plant use. It also handles more stuff per money spent on gear. No cooling and reheating cycles also save energy per ton done.

Steady heat is a core plus of semi-continuous work. The even work heat removes energy loss from batch heat cycling.

Energy saving happens through heat reuse and steady heat control. The steady heat also lets you recover heat from products. This saves even more energy.

Worker cost drops due to machine work systems. They need little worker help during normal runs. The smooth work flow cuts the need for constant watching and moving stuff by hand.

Running cost drops come from better gear use. They use less energy per ton done. They recover more product. These things together lower the cost per ton of tire recycling.

Being earth-friendly is more vital in waste handling. Here we see how semi-continuous systems help the earth more. They control smoke better. They recover more stuff. They meet world rules easier. The steady work allows better pollution stopping. It also gets the most material back from old tires.

Semi-continuous systems keep burning steady. This helps smoke control gear work best. The steady gas flow and makeup let air cleaner systems work better.

The steady heat also lowers bad byproducts and smoke spikes common in batch work. This means less harm to our planet. It is also easier to manage.

Stuff recovery gets better through steady work. This gets the most product. It also makes less waste. The steady heat breaks down rubber fully. It also separates products best.

Semi-continuous systems usually get more oil, carbon black, and steel back than batch ways. This makes the whole tire recycling process better for our earth.

Earth rule following gets better from the steady work of semi-continuous systems. The even smoke and waste levels make watching and reporting simpler.

The better work control also helps follow strict earth rules for waste jobs.

Tech changes always bring problems. This talk points out possible hurdles in using semi-continuous pyrolysis. These include gear needs, worker training, and supply chain shifts. Knowing these helps plan a good move from old batch ways to newer continuous systems.

Switching from batch to semi-continuous needs big place changes. Old batch places may need large upgrades. They must fit continuous feeders, machine controls, and new stuff movers.

Fitting new control systems with old plant gear can be tricky. This needs careful plans. Gear that does not match can cause work issues during the change.

Running semi-continuous systems needs new skills. Workers must know continuous control ideas. They must run machine systems. They need to fix problems well.

The change time needs full training. This makes sure workers can run the more complex continuous systems well. This training cost is key for good setup and top work.

Semi-continuous work needs steady tire flow to run well. Companies must change how they collect and store tires. This feeds the continuous system.

Supply chain changes may include more storage space. Better stuff movers may be needed. Collection times may change. This keeps tires coming for smooth work.

As the pyrolysis field grows, picking the right tech partner is key. This part shows Xingfu Energy’s lead spot. It shows their new ideas and world record in semi-continuous pyrolysis solutions. Their know-how and proven gear make them a top pick for reliable, strong tire recycling tech.

Xingfu Energy is a top seller of advanced pyrolysis tech for tire recycling. The firm brings wide know-how in making semi-continuous pyrolysis systems. These meet big plant needs.

Their skill covers all pyrolysis tech types. They are strong in semi-continuous system design and setup. This lets them give full answers that fit exact buyer needs and work settings.

Xingfu Energy uses fresh ideas in their semi-continuous systems. These include smart control tech, better reactor shapes, and built-in machine parts. These upgrades boost work speed, product quality, and run steadiness.

Their tech path aims to get the most stuff back. It also aims to harm the earth less. The firm’s research keeps making semi-continuous pyrolysis better.

The firm’s world setups show good semi-continuous system use. This is across many places and rules. Buyer words often say work runs better, products are better, and things run smoother than old batch systems.

Long buyer ties and repeat orders prove Xingfu Energy’s semi-continuous pyrolysis tech works well. It is trusted for business tire recycling jobs.

Semi-continuous pyrolysis tech is a big step past old batch ways for tire recycling. The better work speed, steady product quality, and money wins make semi-continuous systems the best pick for modern tire plants. Switching from batch to semi-continuous has some hard parts. But the long wins in speed, profit, and earth care make it worth it. Firms like Xingfu Energy give the tech skill and proven gear needed for good semi-continuous pyrolysis setups.

These plants usually handle 10 to 50 tons of old tires daily. The exact amount depends on the system design. Bigger plants can do more. They keep good work conditions and product quality. The smooth work lets them use their size better than batch systems.

Yes, they can take many waste types. These include plastic waste, plant waste, and city trash. But best work needs system tweaks for each waste type. Old tires are still the top use. They are the same and hold much energy.

Set up usually takes 6 to 12 months. Time depends on system difficulty, site prep, and local rule steps. Xingfu Energy gives full project help. This makes sure setup and start go on time. The time covers gear making, site prep, setting up, testing, and worker training.