Waste tire pyrolysis plants play a crucial role in turning discarded tires into useful materials like pyrolysis oil, carbon black, and steel wire. This happens through thermochemical breakdown. Yet, this operation carries substantial operational dangers. These include high-temperature threats, flammable gas leaks, harmful discharges, and possible machine breakdowns. Effective safety control is therefore essential. It reduces these threats and ensures both worker safety and environmental rules are followed.

Waste tire pyrolysis plants change old tires into valuable outputs such as fuel oil, carbon black, and steel wire. This conversion uses high-temperature decomposition without oxygen. However, this method involves considerable safety hazards. These include fire dangers, poisonous discharges, and equipment malfunctions. Grasping these threats is vital. It helps put effective safety actions in place and guarantees smooth running.

Waste tire pyrolysis plants work by warming tires without oxygen. This breaks them down into pyrolysis oil, carbon black, and steel wire. Tyre pyrolysis is a thermochemical activity. It turns waste tyres into valuable outputs like pyrolysis oil, carbon black, and steel wire. Yet, this activity has several built-in dangers. Tyre pyrolysis is a complex method needing careful safety focus. The most frequent hazards involve high working temperatures, flammable gases, and chemical contact.

Pyrolysis reactors function at heats ranging from 400°C to 600°C. Tyre pyrolysis plants run at elevated temperatures. They also handle flammable substances. This creates a major fire and explosion danger without proper safeguards. Leaks of synthetic gas or oil vapor can catch fire. This happens if they touch air or heat sources.

Breaking down tires releases toxic gases. Examples are carbon monoxide and hydrogen sulfide. The pyrolysis activity generates several poisonous fumes. These include carbon monoxide and hydrogen sulfide. Without sufficient airflow or gas treatment setups, these discharges pose severe health threats. Workers and nearby residents are at risk.

The structural strength and safety aspects of pyrolysis machinery are vital. They prevent accidents. Modern designs include special safety parts. These are pressure release valves, automatic heat controls, and rust-proof substances. They help keep operations steady and secure even in tough conditions.

Keeping steady pressure and heat inside the reactor is key. It stops uncontrolled reactions. Automatic sensors and relief valves should monitor changes in real time.

Advanced control setups can spot abnormalities. These include pressure jumps or gas leaks. Emergency stop mechanisms let workers halt activities immediately during unsafe situations. Operators must know the plant’s emergency stop steps. They need to understand how to stop the pyrolysis activity. They also must know how to leave the plant safely if an emergency happens.

Reactors need building substances. These must endure corrosive compounds and extreme heat for long times. Stainless steel mixes or ceramic linings are often used.

Strict operational rules, emergency action plans, and safety zones are fundamental. They minimize dangers in waste tire pyrolysis plants. Clear procedures make sure workers follow best practices. They also react well if emergencies occur.

Definite SOPs reduce human mistakes. They cover startup, operation, shutdown, and upkeep tasks. These rules should be reviewed often. Reviews should use feedback from actual operations.

Facilities must have written emergency action plans. These cover fire outbreaks, chemical leaks, or machine failures. Having a fire safety strategy ready is crucial. This strategy should include steps for leaving the plant during a fire. It should also cover fighting the fire.

Proper labeling is essential. It marks dangerous areas, restricted access spots, PPE zones, and emergency exits. This keeps staff aware during normal work or crises.

Thorough training for operators and maintenance teams is basic. It reduces workplace accidents. Teaching workers about danger spotting, equipment use, and emergency steps boosts overall safety.

Operators need to grasp reactor behavior, control panels, material handling rules, and emergency actions. Tyre pyrolysis plant operators must stick to all safety steps while working there.

Regular workshops keep readiness high. They cover danger recognition like gas leaks. They also teach fire extinguisher use and first aid.

Regular checks make sure workers meet needed skill levels. Certifications might be required. This depends on local rules.

Effective discharge control and waste handling systems are necessary. They reduce the environmental effect of pyrolysis plants. Advanced gas cleaning, wastewater treatment, and rule compliance protect workers and nearby areas.

Efficient gas scrubbing units must capture harmful vapors. They stop releases into the air. If managed poorly, tyre pyrolysis plants can dirty the surroundings. They release dust, smoke, and wastewater.

All wastewater needs treatment before release. Sources include cooling systems or cleaning processes. Solid leftovers like carbon black must be stored safely. Alternatively, they can be processed further.

Plants must follow discharge rules. Environmental protection agencies set these. They cover air quality control measures.

Proactive upkeep stops equipment failures. These failures could cause dangerous events. Planned checks, predictive analysis, and good records help long-term operational safety.

Routine tests prevent surprise breakdowns. These breakdowns might cause accidents. Check valves, pipelines, burners, and seals regularly. Regularly checking and maintaining the equipment at a tyre pyrolysis plant helps. It finds and fixes possible issues before they cause harm.

Using live sensor feedback allows proactive action. Workers can replace parts nearing failure points.

Maintenance logs help audits. They also help study repeating faults or performance issues over time.

Regular safety checks assess rule compliance. They find areas needing betterment. Internal reviews and outside certifications drive ongoing safety improvements.

Routine internal checks ensure SOPs are followed. They also spot areas needing improvement or more training.

Outside approvals validate compliance. Examples are ISO 9001 for quality or ISO 14001 for environment. These match global best methods.

Audit findings should become real improvements. These could be equipment upgrades or procedure changes. They close found gaps.

Qingdao Xingfu Energy is known for advanced pyrolysis methods. It follows safety rules strictly. It also gives full after-sales help. Their focus on new ideas and environmental duty makes them a dependable partner in waste tire recycling.

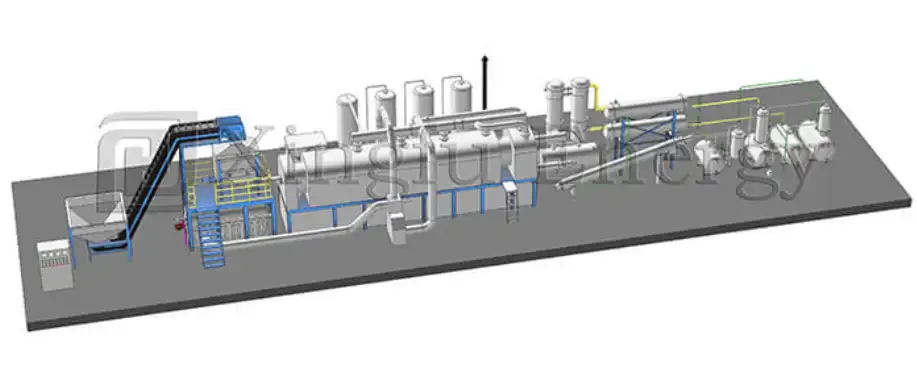

Qingdao Xingfu Energy Equipment Co., Ltd has made fully automatic waste tire pyrolysis plants. These feature multi-level cooling circulation designs. They aim for higher fuel oil recovery rates. These can reach 45%. Whole tyre feed is possible. Cutting isn’t needed. This lowers costs. They use multi-level cooling circulation. This gets more fuel oil.

Their making process includes submerged arc welding. This gets verified by x-ray testing. It ensures mechanical strength under extreme heat stress. They adopt fully automatic submerged arc welding. X-ray detection is used too. This raises the plant safety level.

Help ranges from setup guidance to operator training globally. Xingfu gives complete technical support. This ensures safe long-term running in different site situations.

Waste tire pyrolysis plants offer valuable environmental gains. But they come with natural dangers. This is due to their high-temperature chemical processing nature. Effective safety control is essential. It covers equipment design through training programs. This is key for safe operations. Companies like Qingdao Xingfu Energy show leadership. They deliver engineered answers. These match global safety norms. They also give full service support across all operation stages.

Plants should target ISO approvals. These relate to quality control like ISO 9001. Environmental control like ISO 14001 is important too. Local environmental product use recognitions matter where they apply.

At least every six months is minimum. But drills every three months are advised. This is especially true when handling flammable stuff under high pressure or heat.

Yes. Standard gear includes safety glasses, gloves, a respirator, and a hard hat. This is needed near reactors or when handling dangerous materials onsite.