Choosing the correct dimensions for the core reaction vessel is a vital step in designing a pyrolysis facility. This choice directly affects the amount processed, how heat spreads, and how efficiently the system runs. This part looks at how the nature of the input material, the intended processing volume, and the limitations of the physical site influence the vessel’s measurements.

The size of the core reaction vessel in pyrolysis plants of varying capacities is chiefly governed by the amount and kind of raw material fed into it. For example, handling large items like complete tires or bulky plastic refuse demands greater internal space. This ensures heat spreads well and thermal breakdown happens evenly. Materials that take up more space or are less compact need a larger vessel. This is necessary to handle them without reducing the processing rate.

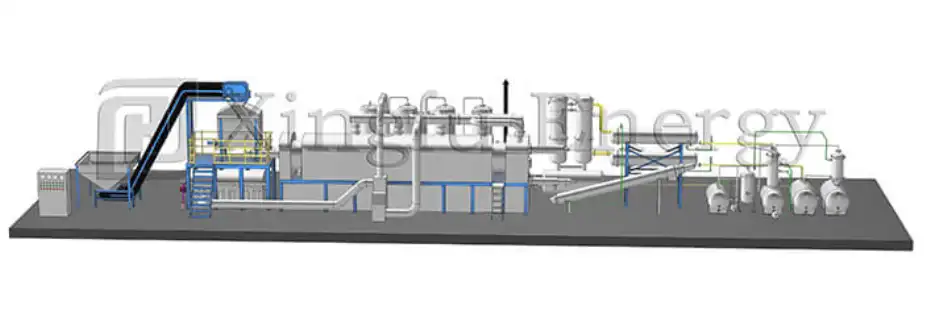

The daily processing volume, measured in tons per day (TPD), is a direct driver for the vessel’s measurements. A facility planned for 50 TPD will need a much bigger core reaction vessel than one running at 5 TPD. For instance, a fully continuous pyrolysis plant handling 50 tons daily might use a vessel measuring 12.5 x 2.2 x 2.5 meters. As the processing rate climbs, the need for better heat transfer surfaces and internal mixing methods also increases. These enhancements are crucial to maintain efficiency.

The physical size of the core reaction vessel must also fit within the available site area. The space needed for a 50-ton per day machine is roughly 33 x 15 x 10 meters. This footprint affects how the entire facility is arranged. It influences safety buffer zones and where supporting equipment, like condensers and feeding systems, can be placed.

Qingdao Xingfu Energy tackles these issues. They provide custom-sized reaction vessels that match the input material volume, desired output, and the spatial restrictions of your site plan.

As pyrolysis facilities get bigger, choosing the right construction substance becomes even more critical. The material must endure thermal strain, chemical wear, and physical damage. Here, we examine the balance between cost and durability for vessels handling different input types and operational settings.

Larger capacity core reaction vessels face extended periods of intense heat cycles. Therefore, resisting thermal stress is essential. These vessels often run non-stop at high temperatures, typically between 400 and 600 degrees Celsius. They demand materials that can handle expansion from heat without bending or cracking over extended use.

Different raw materials, like plastic refuse, tires, or oil sludge, release various chemical compounds during pyrolysis. Using different raw inputs yields different oil ratios, signifying varied chemical mixes inside the vessel atmosphere. This calls for substances resistant to chemical wear. Choices like stainless steel (grades 304 or 316) or special alloy linings become necessary. The choice depends on the presence of elements like chlorine (from PVC) or sulfur compounds.

Selecting the vessel substance involves balancing initial expense against expected service life. The typical operational lifespan is 5 to 8 years. Carbon steel is cost-effective upfront. However, it might need more frequent repairs compared to higher-grade stainless steels. These superior steels offer longer operational life with less downtime.

Qingdao Xingfu Energy delivers tailored substance solutions. These are based on your facility’s scale and the profile of your raw material. This ensures the best compromise between cost-effectiveness and durability.

Reaction vessel sizes vary widely, from small batch units to large continuous industrial systems. This variation depends on capacity. This section outlines typical specifications and design aspects for small (up to 5 TPD), medium (6-15 TPD), and large-scale (16+ TPD) facilities.

Small-scale pyrolysis plants usually employ compact batch-type reaction vessels. These systems have limited automation. They are well-suited for new ventures or locations with confined space. The materials used often include carbon steel. This choice is driven by the need for lower initial capital expenditure.

These vessels might feature basic rotating designs with manual loading systems. Heat retention is usually achieved using refractory bricks instead of more advanced liners.

Medium-scale plants find a middle ground between automation and adaptability. They often use semi-continuous systems. These can manage moderate volumes while preserving energy efficiency.

These vessels might include partial stainless steel linings in high-stress areas. Carbon steel is retained elsewhere to effectively control costs.

Large-scale pyrolysis plants require fully continuous systems. These must operate without stopping for long stretches under intense heat and pressure.

Such vessels demand sophisticated engineering methods. These include seamless welding, thicker wall sections, precise temperature management systems, and substances resistant to chemical wear. Full stainless steel construction or special alloys are often used. This ensures the vessel’s integrity under constant heavy load.

Qingdao Xingfu Energy specializes in building large-scale reaction vessels. They use modern metallurgy and strict quality control systems. These meet demanding industrial standards across global markets.

The choice of vessel substance—be it carbon steel, stainless steel, or special alloys—depends on heat tolerance, resistance to chemical wear, and total cost of ownership. We compare substance properties and their suitability for different pyrolysis uses.

Carbon steel remains popular because it is affordable and easy to work with. However, it has limited ability to resist chemical wear in acidic or chlorine-rich settings. Such environments are common in plastic pyrolysis operations.

Grade 304 stainless steel offers good resistance to oxidation. But it may deteriorate faster when exposed to chlorine compounds like those from PVC. Grade 316 contains molybdenum. This boosts its resistance against chlorides. Therefore, it is more suitable for harsh conditions found in high-capacity plastic waste pyrolysis plants.

For extremely demanding situations involving mixed waste streams or continuous high-load operation, alloy steels combined with refractory linings offer superior durability. They resist both mechanical abrasion and chemical attack.

Qingdao Xingfu Energy provides a wide selection of substance choices. This includes hybrid alloy-steel options. They match your specific process conditions to ensure long-term reliability.

Operating conditions like high heat (400-600°C) and variable pressure impose strict demands on vessel engineering. This section discusses how these factors impact wall thickness, joining methods, and safety buffers.

Higher capacity plants generally run at higher average temperatures. This requires strong thermal insulation strategies. Achieving even heat spread becomes critical. It avoids hot spots that could harm vessel walls or lower yield efficiency.

Batch systems typically operate under normal or slightly reduced pressure using vacuum pumps. Continuous systems, however, must manage consistent internal pressure levels. They use pressure relief valves and gas recovery lines to meet safety rules.

Higher pressures require increased wall thicknesses. They also demand strict joining standards, like X-ray-tested seam welds. This prevents leaks or structural failure under repeated loading.

Qingdao Xingfu Energy designs each reaction vessel according to exact pressure and heat profiles. They ensure structural integrity through advanced joining methods and thorough testing.

The choice of vessel substance directly affects how often maintenance is needed and the cost of downtime. We explore how resistance to wear, surface enhancements, and the abrasiveness of the raw material guide decisions. The goal is to balance longevity with operational efficiency.

Substances facing frequent abrasive contact need strong resistance to wear. This is especially true when processing rubber or composite materials. Surface hardening treatments like cladding or ceramic coatings may be applied where useful.

Unplanned stoppages due to material weakening can severely hurt profitability. This is particularly true in high-capacity continuous plants. Here, every hour impacts the timeline for recovering the investment.

Choosing substances based on expected running hours before maintenance helps optimize total lifecycle costs. It also minimizes production halts for repairs. This is vital when handling abrasive inputs like shredded tires or plastic-coated cables.

Qingdao Xingfu Energy helps clients by performing detailed lifecycle assessments during the design phase. This enables smarter substance selection aligned with maintenance objectives across different capacity pyrolysis plants.

Qingdao Xingfu Energy provides comprehensive solutions. These range from custom vessel fabrication to technical assistance. Learn how their know-how in substance choice and scalable designs ensures top performance for pyrolysis plants of any size.

With years of experience building small batch units up to fully automatic 50+ TPD systems, Qingdao Xingfu Energy delivers end-to-end solutions. These are precisely tailored to your processing needs—from layout planning to final setup support.

Whether you need carbon steel for budget-limited setups or advanced alloy composites for tough waste streams, Qingdao Xingfu Energy offers a broad portfolio of tested substances. These are engineered for longevity under real-world conditions across various capacities. This spans small pilot plants to large industrial operations.

From feasibility studies to technical advice during installation—and ongoing post-sales maintenance guidance—their team ensures your investment performs optimally throughout its life. This holds true regardless of scale or complexity.

Choosing the right reaction vessel size and construction substance is fundamental when designing pyrolysis plants of different capacities. This ranges from small batch units using carbon steel to fully automated continuous systems needing special alloys. Factors like input type, daily processing targets, available space, temperature/pressure ranges, and maintenance schedules all contribute to defining the best specifications. By leveraging Qingdao Xingfu Energy’s expertise at every stage—from custom building to setup—they help clients navigate these complexities efficiently. This maximizes operational dependability.

Grade 316 stainless steel is recommended. This is due to its superior resistance against chlorinated compounds released during plastic breakdown, especially from PVC-containing feeds.

Core design principles remain similar across scales. However, scaling up usually needs structural strengthening. This includes thicker walls, better mixing mechanisms, and improved heat controls. Therefore, a design cannot be copied directly without changes.

Maintenance frequency depends on operating hours and how abrasive the input material is. Typically, it includes monthly inspections. Major servicing usually occurs every six months or annually, depending on how intensely the plant is used.