Pyrolysis might sound complex, but it’s a smart way to handle waste. It’s a process that heats up stuff like old tires and plastics in a sealed space without oxygen. This breaks them down into useful things—fuel oil, gas, and carbon leftovers. For anyone worried about trash piles, this offers a fresh path. It cuts down landfill use and pulls energy from what was once junk. Businesses and communities see it as a win for both the planet and their wallets.

Inside a pyrolysis setup, waste gets loaded into a tough reactor. Heat does the work, turning solids into gases. Those gases cool down into oil and other products. The system traps any leftover gas to power the heat, making it efficient. It’s a cycle that keeps going with minimal waste. Tires and plastics, which pile up fast, become resources instead of problems.

Factories, recycling folks, and even small towns can use pyrolysis. It suits places with lots of rubber or plastic waste. Energy companies love the oil for power. Manufacturers grab carbon for new materials. Even local groups can jump in, turning local trash into local energy. It’s a tool for anyone looking to clean up and cash in.

This process turns headache waste into something valuable. It’s not just about getting rid of junk—it’s about making energy that works.

Old tires are tough to break down. Pyrolysis heats them up, pulling out oil that burns like diesel. One load can yield a good chunk of fuel, plus some gas and carbon. This oil powers trucks or generators. The carbon finds use in making rubber or paint. It’s a full-circle deal that keeps tires out of dumps.

Plastics clog landfills, but pyrolysis changes that. Heat breaks them into oil and gas too. The oil can fuel factories or heat homes. Gas helps run the process itself. Leftover carbon goes into new products like ink or tires. It’s a way to reuse what once seemed useless.

Take a plant running day and night. It handles tons of waste, turning it into steady energy. In places like Turkey or Malaysia, setups process 15-20 tons daily. Workers see oil flowing out, gas feeding back, and carbon piling up. These sites prove pyrolysis delivers reliable energy from waste.

| Waste Type | Main Output | Extra Uses |

| Tires | Fuel Oil | Carbon for rubber |

| Plastics | Fuel Oil | Gas for heat |

Pyrolysis isn’t just green—it’s practical. It offers clear gains for those who dive in.

Landfills cost money to run and maintain. Pyrolysis skips that. Instead of paying to dump, you process waste onsite. The oil and gas you get can offset costs or sell for profit. Communities save space and cash. Businesses turn a chore into a revenue stream.

People care about the planet. Using pyrolysis shows you do too. Companies that adopt it gain trust from customers who value eco-friendly moves. Towns with these systems draw attention as leaders in waste handling. It’s a badge of honor that boosts your name.

The oil from pyrolysis works in engines or heaters. Gas powers the plant itself, cutting fuel bills. Communities get a local energy source, lessening reliance on outside power. Businesses enjoy a consistent supply, even in tough times. It’s energy you control.

Pyrolysis sounds great, but it’s not perfect. Some hurdles need attention.

Setting up a pyrolysis plant takes cash. The reactors and systems cost upfront. But over time, the oil and gas pay off. It’s a big step that needs planning and patience.

Running these plants isn’t simple. You need trained folks to handle the heat and safety. Finding or training workers takes effort. Once in place, though, they keep things smooth. It’s a skill set worth building.

Every area has waste laws. Working with local rules from the start avoids headaches later. It’s a process, but doable with care.

Real-world examples show pyrolysis at work. These cases highlight its potential.

A plant in Turkey runs 15 tons of tires daily. It pumps out oil for local use and carbon for sale. Workers move waste in, and energy flows out. The site’s been steady since it started, proving tire pyrolysis works.

In Mexico, a setup handles 20 tons of tires and plastics together. Oil fuels nearby factories. Gas keeps the heat going. The team there says it’s cut waste hauling costs big time. It’s a model for mixed waste sites.

Spain’s 15-ton plant runs non-stop. Tires feed in, and oil comes out for power. The carbon sells to manufacturers. Locals see it as a clean energy spot. It’s been a reliable player for years.

Pyrolysis is growing fast. It’s shaping how we handle waste and energy.

New designs make plants faster and cleaner. Better reactors cut energy use. Smarter controls reduce emissions. Researchers keep pushing to make it even better. The future looks brighter with each tweak.

More towns and companies are eyeing pyrolysis. With waste piles growing, it’s a go-to solution. Places with lots of tires or plastics will lead the charge. It could become as common as recycling bins.

This process fits the push for green living. It turns trash into treasure without burning it. Communities that adopt it lead the way in cutting waste. It’s a solid move for a healthier planet.

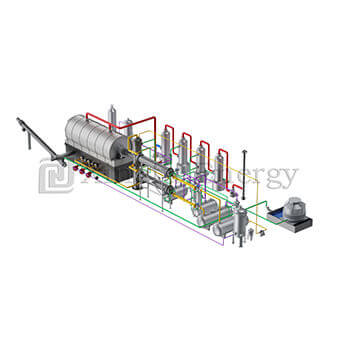

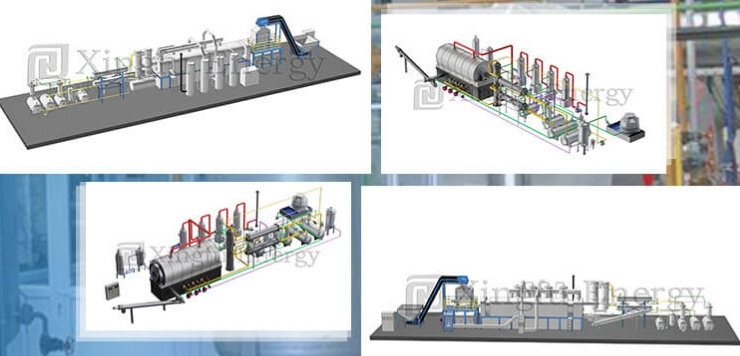

Qingdao Xingfu Energy Equipment Co.,Ltd stands out as a key supplier of waste tires & plastics pyrolysis systems. Founded in 2010 in Qingdao, China, this company blends tradition with innovation. They craft equipment for turning waste into energy, serving over 30 countries. With a strong team of engineers and workers, they build reliable systems backed by CE and ISO certifications. Their focus on quality and global reach makes them a trusted name in the field.

Pyrolysis offers a powerful way to transform waste to energy. It tackles tires and plastics, turning them into fuel and materials. The process saves money, builds reputation, and powers communities. Challenges like costs and rules exist, but success stories prove it’s worth it. As tech grows and adoption spreads, pyrolysis could lead waste management into a greener future. It’s a chance for businesses and towns to shine while cutting trash.

It heats tires and plastics without oxygen, breaking them into oil and gas. This energy powers machines or homes, making waste a resource.

Tires and plastics are the main ones. The process turns them into usable fuel and carbon, cutting landfill use.

Yes, with proper setup. Trained workers and good design keep it safe, turning waste into energy without big risks.

Absolutely. Small plants fit local needs, turning local waste into energy and boosting community pride.