Pyrolysis technology is a game-changer for waste management tire disposal. Old ways like dumping tires in landfills or burning them hurt the environment. Tires take ages to break down. Burning them releases bad stuff into the air. But pyrolysis is a green option. It breaks tires into useful things like pyrolysis oil, carbon black, and steel wire.

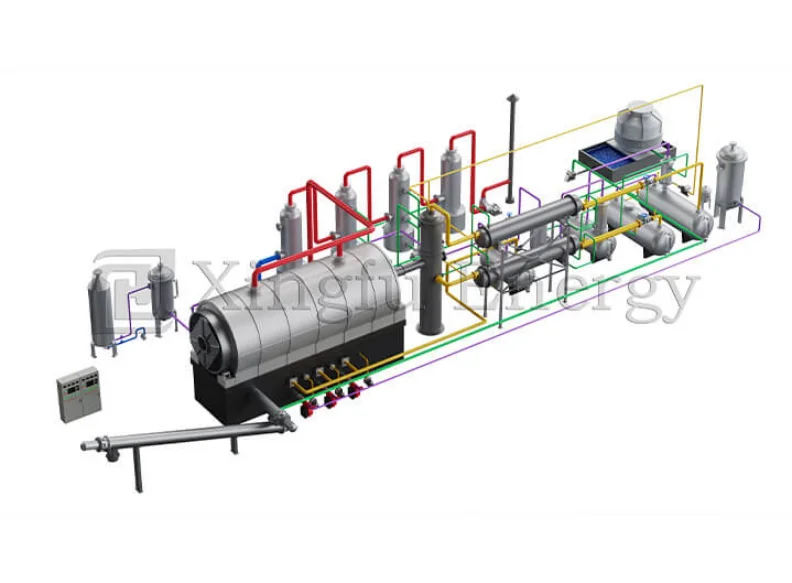

Qingdao Xingfu Energy Co., Ltd. makes top-notch pyrolysis plants. Their Fully Automatic Waste Tyre Pyrolysis Plant lets you feed whole tires without cutting them first. This saves money and makes work faster. The process heats tires in a no-air space. This stops burning and breaks materials down with heat. You get about 40-45% fuel oil, 32-36% carbon black, and 14-16% steel wire. These advances help handle tire waste well. They also bring back useful materials.

Pyrolysis technology cuts the harm from used tire disposal. Unlike old methods that make greenhouse gases and toxins, pyrolysis keeps air cleaner. For example, Qingdao Xingfu Energy Co., Ltd.’s Whole Tyre Pyrolysis Plant uses pulse dust removal systems. These stop dust from escaping during work. Also, the syngas made during pyrolysis can be used again in the plant. This cuts the need for outside fuels.

This closed-loop setup fits global green goals. It turns waste into useful stuff while keeping nature safe. Making carbon black and steel wire from tires helps industries that need these materials. It builds a circular economy.

Plastic waste is a huge problem worldwide. It doesn’t break down easily and is used everywhere. Pyrolysis of plastic waste is a great way to manage it. It turns plastic into fuel oil and other helpful products. Qingdao Xingfu Energy Co., Ltd.’s Fully Automatic Plastic Pyrolysis Plant gets 60-85% fuel oil and 10-30% carbon black.

These plants handle mixed plastics from city trash or factories. They cut down on landfill use. They also make energy-rich products that can replace regular fuels. Plus, semi-automatic plants work for smaller setups or places with fewer resources.

The circular economy is about cutting waste by reusing and recycling. It sees waste as something to use again, not throw away. Pyrolysis in solid waste management fits this idea perfectly. It helps recover materials like oils, carbon black, and metals from trash.

Using circular economy ideas in waste management means focusing on tech like pyrolysis. This saves natural resources. It also lowers the harm from digging up new materials.

Pyrolysis plants are key to getting resources back in a circular economy. They turn solid wastes like tires and plastics into products you can sell. This cuts the need for new materials. For example, Qingdao Xingfu Energy Co., Ltd.’s Broken Tyre Pyrolysis Plant has sealed, hot feeds. These save heating time and make top-quality products.

Also, pyrolysis oil works as fuel for furnaces or diesel engines. Carbon black can be turned into granules for rubber or paint. Steel wires from tires go back into metal making. This reuse helps industries and the planet.

Old ways of used tire disposal, like burning or dumping, cause big problems. Burning sends bad chemicals like dioxins into the air. Landfilled tires take up lots of space. They break down super slowly.

These methods hurt nature. They also waste valuable stuff inside tires. Pyrolysis technology fixes this gap.

Pyrolysis uses heat in a no-air space to break tires down. It makes useful products:

Fuel Oil: This makes up 40-45% of the output. It can be cleaned up or used as fuel for factories.

Carbon Black: This is 32-36%. It’s used in rubber goods or as a color in paints.

Steel Wire: This is 14-16%. It goes back to steel factories.

Qingdao Xingfu Energy Co., Ltd.’s designs ensure high recovery and follow green rules.

Recycling tires with pyrolysis creates money-making chances. It turns waste into products to sell:

Energy Production: Fuel oil from tires works as a new energy source.

Material Supply: Carbon black and steel wire meet industry needs.

Job Creation: Running pyrolysis plants makes jobs in engineering, transport, and factories.

These perks show how pyrolysis waste to energy can boost both green goals and money.

Pyrolysis plants are growing worldwide as countries look for green waste solutions. Europe, North America, and parts of Asia lead the way. They have strict green rules and know about circular economy ideas. For example, Europe spends big on pyrolysis to tackle used tire disposal and plastic waste.

In Asia, places like China and India use pyrolysis to handle growing waste. Qingdao Xingfu Energy Co., Ltd., based in Qingdao, China, helps a lot. Their Fully Automatic Waste Tyre Pyrolysis Plant and Broken Tyre Pyrolysis Plant recover resources well. North America also uses pyrolysis to cut landfill use and find new energy sources. This shows a global move to green practices.

Government rules push pyrolysis plants forward. Many countries make laws to cut landfill use and boost recycling. The European Union’s Circular Economy Action Plan tells countries to invest in tech like pyrolysis.

In the U.S., states give tax breaks or grants to businesses using green methods. These help with used tire disposal or pyrolysis of plastic waste. China has tough rules on solid waste. Companies like Qingdao Xingfu Energy Co., Ltd. follow these with their Fully Automatic Plastic Pyrolysis Plant. It meets green standards and gets high fuel oil and carbon black.

The future of pyrolysis is about making it bigger for industries. Large pyrolysis plants can handle tons of waste. This helps cut global trash. New designs make it easier to process mixed plastics, city trash, or factory waste.

For example, multi-level cooling systems boost fuel oil output and save energy. Qingdao Xingfu Energy Co., Ltd.’s Broken Tyre Pyrolysis Plant uses sealed, hot feeds. This cuts costs and keeps quality high. Pyrolysis waste to energy also makes syngas. This can power factories or plants. This mix of less waste and more energy makes pyrolysis a key green tech.

Teamwork between industries is vital for green waste solutions with pyrolysis. Waste companies, factories, and governments can work together. This drives new ideas and follows green rules.

For example, tire makers can team up with pyrolysis plants. They can recycle old tires into materials for new tires. Industries needing carbon black or steel wire can use pyrolyzed products instead of new ones. Education and partnerships also help spread pyrolysis. Qingdao Xingfu Energy Co., Ltd. offers custom solutions. These fit specific needs and push green goals.

Used tire disposal is handling thrown-out tires. You can dump, burn, or recycle them with tech like pyrolysis.

Pyrolysis in solid waste management breaks waste into useful stuff like fuel oil, carbon black, and steel wire. It works without air.

Yes, pyrolysis of plastic waste turns plastics into fuel oil and carbon black. It cuts landfill use.

Qingdao Xingfu Energy Co., Ltd. has cool features like sealed, hot feeds and multi-level cooling. These make work efficient and green.