Have you ever wondered how industries turn waste into something useful? Pyrolysis does that. It breaks down materials like plastics and tires without burning them. This process creates fuel, char, and gas. If you run a factory or deal with waste, this guide shows the upsides, the tough parts, and why small test setups matter. We dig deep into how it works in real life. Let’s start.

Pyrolysis heats up organic stuff in a closed space with no air. Temperatures range from 350°C to 700°C. No oxygen means no flames. Instead, big molecules split into smaller ones. Think syngas, bio-oil, and char.

Common inputs include plastic scraps, old tires, farm waste, city trash, rubber bits, and factory sludge. Outputs vary. Gas makes up 20-30%, good for burning. Liquid bio-oil hits 35-50%, fine for boilers or more processing. Solid char is 20-30%, works as carbon or soil booster.

For folks handling lots of waste, pyrolysis cuts trash and pulls out value. It fits right into plans for less waste and more reuse.

Pyrolysis brings real gains. It shrinks waste by up to 90%. That means less landfill space and lower fees.

Energy side? Syngas packs 16-20 MJ/kg heat value. Use it like regular fuel. Saves on buying more.

Pull out resources. Carbon black from tires sells for $0.40-0.60 per kg. Bio-oil swaps for diesel in heaters.

Meets green rules. Cuts landfill use and carbon release. Helps hit targets.

Fits circular thinking. Turns one-way waste into loops. Boosts material use.

If costs rise for raw stuff, this helps your bottom line.

Pyrolysis shows up in many fields.

Plastic recycling: World makes over 400 million tons yearly. Pyrolysis grabs back monomers and fuel.

Tire breaking: Market for tire oil heads to $550 million by 2027. Big money there.

Biomass shift: Farm scraps yield up to 50% bio-oil. Rural spots cash in.

Oil and gas: Boosts low stuff value. Helps refinery cash flow.

Hazard waste: Breaks bad stuff safe. Lowers risks.

Handles different stuff. Makes products ready to sell.

| Industry | Key Input | Main Output | Market Value Example |

| Plastic Recycling | Mixed plastics | Fuel oil, monomers | High demand for recycled fuel |

| Tire Processing | Waste tires | Carbon black, oil | $550M global by 2027 |

| Biomass | Agricultural waste | Bio-oil | Up to 50% yield |

| Oil & Gas | Low-grade feed | Upgraded fuel | Improves economics |

| Hazardous Waste | Contaminated materials | Safe by-products | Reduces liabilities |

This table lays out quick views. Pick what fits your setup.

Not all smooth. Pyrolysis has hurdles.

Feed changes matter. Over 10-15% water drops quality and heat use.

Tune the run. Reactor type, time inside, heat speed affect what comes out.

Gas handling: Volatiles need good cooling and cleaning.

Upfront money high. Big plants cost $3-10 million.

Rules tight. Handle smoke and leftovers right.

Spot these early. Balance tech with cash flow.

Tackle one by one for success.

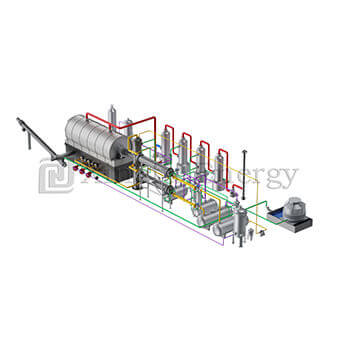

Good setup needs key parts.

Prep feed steady. Cut size, dry to under 15% water.

Reactor advanced. Pick fixed-bed, fluidized-bed, or rotary kiln for your flow.

Heat even. Avoid hot spots or burn.

Collect products. Use stages for cooling, scrub gas, grab char.

Controls auto. Watch heat, pressure, gas mix live.

Keeps runs safe and steady.

Before big jump, test small. Pilot plants prove ideas.

Run like real. Adjust settings without big fails.

Test mixes. See yields from different stuff.

Check money. Figure flow, power use, sell value.

Get data. For designs, permits, talks with money folks.

Cut risks. Find blocks, dangers, smoke issues first.

Must-have for big spends. De-risks path to full run.

If you plan pyrolysis, start pilot. Saves time and cash.

Need solid gear? Qingdao Xingfu Energy Equipment Co., Ltd. fits. Started 2010 in Qingdao, China. They build waste tires & plastics pyrolysis systems, boilers, pressure vessels.

Strong team. 78 tech people (20% staff), 28 engineers, 136 skilled hands (36%), 65 good welders (47%).

Big space: 70,500 sq m total, 21,000 plant.

Sales hit over 100 million RMB from 2012.

Certs: ASME, CE, ISO9001. A-level boiler make, pressure vessel permits, install license.

Exported 30+ countries: Europe, Africa, Latin America, South East Asia, Middle East.

Plants types: fully auto (5,000-20,000 T/y), whole tire (10-20 T/day), broken tire.

Recovery: 40-45% oil, 32-36% carbon black, 14-16% steel wire, 5-8% syn gas.

Contact [email protected]. They match your needs.

Pyrolysis changes waste game. Benefits cut costs, meet rules. Challenges need smart plans. Pilot plants guide safe. Right system powers your work.

Pyrolysis heats waste without air to make fuel, char, gas. Benefits include waste cut, energy save, resource pull. Great for industries.

Feed changes, gas handle, high costs, rules. But good systems like waste tires & plastics pyrolysis system fix them.

They test small, cut risks, check yields. Lead to better full runs.

They build strong, certified gear. Exported wide, high recovery rates.

Oil 40-45%, carbon black 32-36%, steel 14-16%, gas 5-8%. Useful stuff.