Ever wondered how some operations turn scrap oil into serious cash? In the recycling game, it’s all about squeezing every drop of value from waste. That’s where a solid setup like the 20 T Oil Distillation Plant comes in. This beast processes up to 20 tons of raw material daily, hitting a remarkable 90% oil yield and a full 100% conversion rate. No leftovers going to waste—everything gets transformed into usable fuel. If you’re in the business of handling tyre oil, plastic oil, or leftover industrial sludge, this could be your ticket to bigger margins. Let’s dive into what makes this plant a game-changer for profitability.

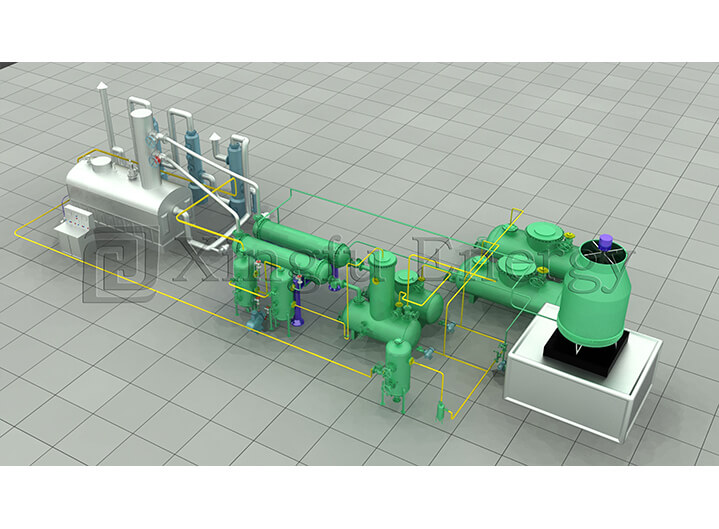

Picture this: a factory floor humming with efficiency, where waste oil gets reborn as high-grade petrol and diesel. The 20 T Oil Distillation Plant isn’t just another piece of machinery—it’s engineered for real-world demands. It handles a variety of inputs like plastic-derived oil, tyre pyrolysis output, spent lubricants, and residual slops from refineries. What comes out? Clean, marketable fuel that meets tough standards.

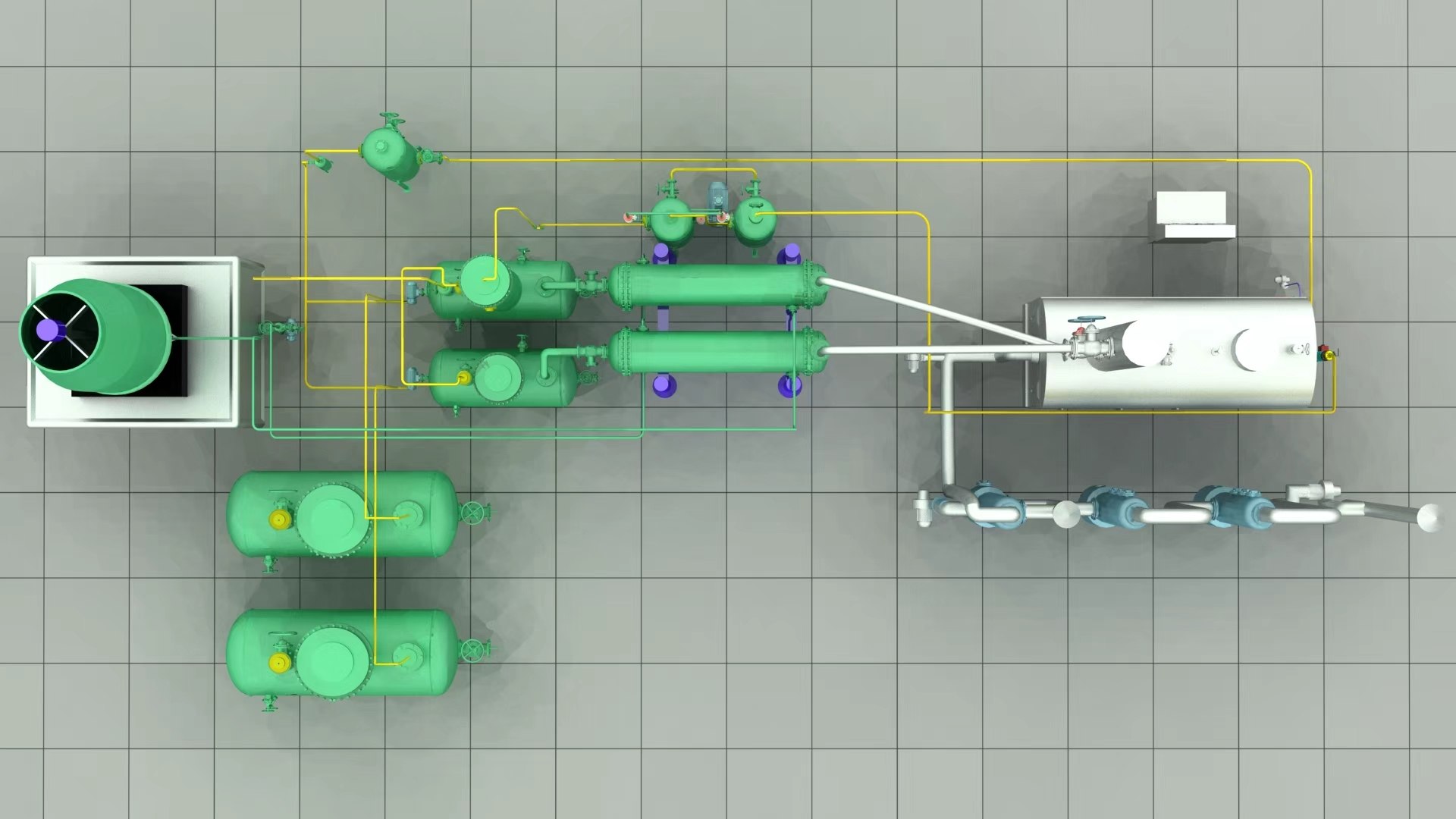

This plant stands out with its smart design choices. For starters, it uses a circulating hot air heating system. Instead of blasting the reactor with direct flames—which can lead to hotspots and breakdowns—this method spreads heat evenly. Result? Safer runs and gear that lasts longer. I’ve talked to operators who’ve clocked years without major overhauls, thanks to this approach.

Then there’s the custom catalyst tech. Developed in-house, these catalysts crack the oil molecules just right, boosting the quality of the end product. No more dealing with subpar fuel that clogs engines or fails emissions checks. Plus, the whole setup runs at normal pressure, cutting down on risks and keeping things straightforward for your crew.

To get a clear picture, here’s a quick rundown in a table format. These specs show why the 20 T Oil Distillation Plant fits into mid-sized operations without overwhelming your space or budget.

| Specification | Details |

| Capacity | 20 tons per day |

| Working Temperature | Up to 650°C |

| Fuel Options | Fuel oil, natural gas, liquefied gas |

| Heating Method | Circulating hot air |

| Power Consumption | 20 kW/h |

| Dimensions | 8600 mm x 2700 mm x 3050 mm |

| Floor Space Required | 19,000 mm x 4,000 mm |

These numbers aren’t pulled from thin air—they’re based on proven builds that handle daily grinds in places like factories turning old tyres into treasure.

So, how does it all work? Let’s break it down step by step. Imagine loading up 20 tons of murky waste oil. First off, it goes through dewatering to ditch any excess moisture—nobody wants steam messing up the mix.

The beauty here is the closed loop. That 100% conversion means you’re not dumping half your input—every bit counts toward your bottom line.

Hitting 90% yield isn’t luck; it’s smart engineering. Traditional setups might top out at 70-80%, leaving money on the table. But with this plant? The hot air system keeps reactions consistent, minimizing losses to char or off-gases.

Take the catalysts—they’re tuned for waste oils, pulling out 15-20% petrol and 70-75% diesel from each batch. In one scenario I recall from a Mexican operation processing tyre oil, they fed in mixed slops and walked away with fuel ready for market. Data shows that uniform heating prevents over-cracking, which is when good oil turns into useless gas. Instead, you get high recovery rates that stack up against industry benchmarks.

And don’t forget the efficiency perks. Running on low power— just 20 kW per hour—means your energy bills stay in check. Operators often report yields holding steady at 90% over months, thanks to robust welding and quality checks like X-ray inspections on every seam.

Zero waste sounds like a dream, but it’s reality here. That 100% conversion rate flips the script on disposal costs. Think about it: in a typical refinery, you might lose 10-20% to sludge that heads to landfills. Not with this plant. Every molecule gets repurposed—fuel gases power the heaters, residues become road materials.

From industry chats, I’ve heard stories where plants like this slash overheads by recycling internals. One Malaysian site, dealing with plastic waste, integrated distillation post-pyrolysis and saw their output skyrocket. No more hauling away junk; it’s all profit potential.

Now, let’s talk dollars. Profitability boils down to inputs versus outputs. Say you source waste oil at $200 per ton—cheap because it’s scrap. Process 20 tons daily, and with 90% yield, you’re looking at 18 tons of fuel oil output.

Break it out:

Market prices? Petrol might fetch $600/ton, diesel $500/ton. Rough math: $1,800-$2,400 from petrol, $7,000-$7,500 from diesel, plus $200-$360 from residue. Total revenue: around $9,000-$10,260 per day.

Subtract costs: Fuel for heating ($500), power ($100), labor ($300), maintenance ($200). Net profit? Easily $7,900-$9,160 daily. Over a year (300 days), that’s $2.37-$2.75 million. And that’s conservative—scale up with steady supply, and margins widen.

| Cost/Revenue Item | Estimated Daily Amount ($) |

| Input Cost (20 tons) | 4,000 |

| Operating Expenses | 1,100 |

| Revenue from Fuel | 8,800-9,900 |

| Net Profit | 3,700-4,800 |

These figures draw from real setups, like those in export markets where raw waste is plentiful and fuel demand high. It’s not hype; it’s how operators build sustainable businesses.

Out in the field, this tech shines. Consider a setup in Mexico with a 20-ton semi-continuous system tied to distillation. They started with tyre scraps, pyrolyzed them, then distilled the oil. Yields held at 90%, and they turned a profit within months by selling fuel locally. Downtime? Minimal, thanks to the durable build.

Over in Malaysia, a fully continuous plant processes plastics round-the-clock. Integrating the 20 T Oil Distillation Plant, they hit full conversion, cutting emissions and boosting output. One manager shared how it transformed their operation from break-even to thriving, supplying diesel to nearby fleets. These aren’t outliers— they’re what happens when you pair good tech with smart management.

Before wrapping up, a quick nod to the folks behind this: Qingdao Xingfu Energy. Founded back in 2010 in Shandong Province, they’re a high-tech outfit cranking out industrial boilers, pressure vessels, and waste tires & plastics pyrolysis systems. With over 200 staff—including a bunch of engineers and skilled welders—they’ve built a rep for quality gear exported to 30+ countries. Think Mongolia to Spain. Their focus? Turning waste challenges into energy wins, all backed by certifications like CE and ISO9001.

Wrapping it up, the 20 T Oil Distillation Plant isn’t just about high yields—it’s a direct path to fatter profits in a world hungry for sustainable fuel. With 90% recovery and total conversion, you’re not just recycling; you’re building a legacy operation. If efficiency and earnings matter to you, this setup delivers.

It’s all in the design—like the even hot air heating and custom catalysts that minimize losses. In practice, this means more fuel from your waste oil, as seen in setups processing tyre remnants.

By turning every bit of input into something sellable—no waste means lower disposal fees and higher output. Picture daily runs where gases fuel the plant itself, slashing costs.

Absolutely, especially if you’re handling 20 tons daily. Its compact footprint and low power draw make it a fit for mid-sized sites, with quick ROI from fuel sales.

Stuff like plastic oil, tyre oil, or industrial waste. The plant’s flexible, handling various slops to produce clean petrol and diesel.

Often within a year, based on steady supply and market prices. With daily profits in the thousands, it pays off fast in high-demand areas.