Picture a big junkyard piled high with old tires. They used to roll down highways. Now they just sit there and leak harmful stuff into the ground. It’s a common sight in industrial areas. And it’s a real headache for waste managers. But what if those same tires could fuel trucks again? Or heat factories without any guilt? That’s exactly what happens when you pair pyrolysis with distillation. This combo doesn’t just recycle. It turns waste into something truly profitable. At its heart, the process breaks down tough materials like tires using heat in a low-oxygen environment. That’s pyrolysis. Then it polishes the resulting oil through distillation into fuels that meet real standards. We’re talking about a complete closed loop. It takes waste tires and turns them into standard fuel. For companies serious about sustainability without the usual headaches, this integrated approach changes everything.

Picture a big junkyard piled high with old tires. They used to roll down highways. Now they just sit there and leak harmful stuff into the ground. It’s a common sight in industrial areas. And it’s a real headache for waste managers. But what if those same tires could fuel trucks again? Or heat factories without any guilt? That’s exactly what happens when you pair pyrolysis with distillation. This combo doesn’t just recycle. It turns waste into something truly profitable. At its heart, the process breaks down tough materials like tires using heat in a low-oxygen environment. That’s pyrolysis. Then it polishes the resulting oil through distillation into fuels that meet real standards. We’re talking about a complete closed loop. It takes waste tires and turns them into standard fuel. For companies serious about sustainability without the usual headaches, this integrated approach changes everything.Let’s start with the basics. Pyrolysis isn’t some fancy new trick. It’s a simple thermal process that’s been around for years. Engineers have fine-tuned it for today’s waste problems. You feed shredded tires or plastics into a sealed reactor. You heat it to about 400-500°C. And you keep oxygen completely out. No open flames. Just steady, controlled breakdown. The tires release oils, gases, and solids. It’s like slow-cooking rubber until it gives up its valuable parts.

In real life, the numbers make sense. A typical 20-ton batch of waste tires often produces 40-45% oil by weight. It also gives carbon black for new tires or pigments. Plus syngas you can burn for power on-site. We’ve seen plants in places like Malaysia that handle 15 tons a day. They produce enough oil to cut diesel imports. It’s straightforward chemistry backed by solid engineering. The raw pyrolysis oil comes out dark and thick. It’s full of promise. But it also carries impurities like sulfur and water. That oil clearly needs refining.

This single step cuts landfill waste by up to 90%, according to industry reports. Yet here’s the catch. Without the next stage, that oil stays unfinished. That’s where distillation steps in. It turns rough material into something clean and useful.

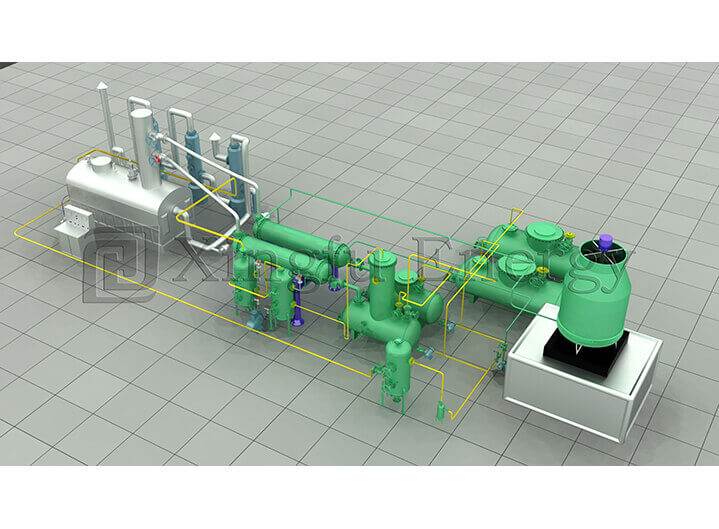

Now picture taking that fresh pyrolysis oil—straight from the reactor and smelling like hot asphalt—and pumping it into a distillation unit. That’s where an oil distillation plant really shines. It separates the good stuff from the junk through careful heating and cooling. These aren’t backyard setups. They’re large, industrial machines built for safety, scale, and steady output.

A good example is the 20-ton oil distillation plant. It processes a full batch of raw oil from pyrolysis runs. It works under normal pressure at temperatures up to 650°C. First, it removes extra water. Then the oil enters the reactor for gasification. Lighter parts like petrol rise and cool into storage tanks. Heavier diesel gets refined in a separate tank. The whole system uses a circulating hot air method. No direct flames touch the reactor walls. That keeps things safer and helps the equipment last longer.

What do you get? Solid results: 15-20% petrol recovery, 70-75% usable gas fractions, 2-5% flammable syngas you can burn on-site, and only 10-18% residue for asphalt or further use. Overall oil recovery reaches 90%. Conversion is nearly 100%. Power use stays low at about 36 kW total. It consumes roughly 20 kWh per run. You can fuel it with natural gas or even the syngas from the process. Operating costs stay reasonable—around 300 kg of fuel per batch.

Walk into a working unit and you’ll hear a steady hum of efficiency. Raw oil pumps in after the pyrolysis cooldown. The catalyze tower does the main work. It separates vapors as they rise. Condensers—big, finned coils—capture the liquids. Petrol flows to one tank. Diesel goes to another. That diesel then moves through an oil reconcile tank for final adjustments. It comes out as high-quality fuel oil that passes basic combustion tests. Flue gases get scrubbed and recycled. Emissions stay low.

Safety is built in from the start. Full submerged arc welding with X-ray checks. Pressure controls keep everything stable. No explosion risk. The hot air loop prevents hotspots. In a real Midwest recycling operation that feeds tire oil from 10 tons of daily scrap, they report diesel clean enough for generators. Fuel purchases dropped 60% in the first year.

Distillation by itself works well for crude oil fields. But it misses the waste-to-fuel angle. Pyrolysis alone leaves you with unrefined sludge. Put them together and each part strengthens the other. Energy flows in a loop. Syngas from distillation heats the pyrolysis reactor. Environmentally, you cut CO2 compared to virgin fuel production. Studies show up to 70% less than burning tires. And the economics? A plant like this often pays back in 18-24 months at current oil prices. That’s based on 85% recovery in continuous operations.

So how does everything connect into a true “from waste tire to standard fuel” loop? It’s not a straight line. It’s a smart cycle where outputs feed right back in. You start with curbside tires. Shred them on-site to save hauling costs. Load the chips into the pyrolysis reactor. They turn into oil (45%), char (35%), and gas (20%). That oil goes straight to distillation. It yields diesel-grade fuel—up to 30% of the input weight—and petrol for blending.

Here’s the flow in a clear table:

| Stage | Input | Key Process | Output | Reuse Potential |

| Collection & Shredding | Whole waste tires (e.g., 20 tons) | Mechanical breakdown | Tire chips | Reduces volume by 80% for easier handling |

| Pyrolysis | Tire chips | Thermal cracking at 450°C | Raw oil (45%), carbon black (35%), syngas (20%) | Oil to distillation; char for rubber filler; syngas for plant power |

| Distillation | Raw pyrolysis oil (9 tons) | Fractional separation at 650°C | Diesel fuel (70%), petrol (15%), residue (15%) | Diesel for vehicles/heaters; petrol for solvents; residue for roads |

| Byproduct Loop | All syngas & residue | On-site combustion/recycling | Energy & materials | Cuts external fuel needs by 50%; sells char for $200/ton |

This isn’t just theory. In a Bulgarian tire yard, they moved from batch to semi-continuous. They reached 98% uptime. Tires that once clogged landfills now power local fleets. Nothing goes to waste. Customers stay loyal because the system keeps paying for itself. Fuel bills drop. And you meet stricter regulations with ease.

Operators who run these plants tell the same story. Two years ago, a plastics processor in Turkey added a 15-ton pyrolysis line and a matching distillation unit. They turned 300 tons of monthly scrap into 90 tons of diesel. That was enough to fuel their own trucks and sell the rest. Emissions fell 65% compared to old incinerators, according to local checks. The plant ran smoothly even through a hot summer.

In Mexico, a border-town operation mixed oily sludge from auto shops with tires. They fed it into distillation and boosted yields to 85%. First-year fuel sales hit $150K. One manager put it simply: “We went from paying to haul waste to getting paid for product. The loop closed. So did our margins.” These cases aren’t rare. Across 30 countries, similar stories show payback in under two years. Plants handle 20 tons daily without major issues.

Why go for the full package? It’s simple. Separate units waste time and money. A standalone pyrolysis plant gives you raw oil. But shipping it off-site for refining creates logistics problems and lost profit. Add distillation and you stay in control. You produce fuel when you need it. You adjust it to local specs like low-sulfur diesel.

The system scales easily too. Begin with batch processing for testing. Then switch to continuous for higher volume. Maintenance stays straightforward. Parts are modular. Remote monitoring helps. Once you’re in the loop, results keep building. Costs fall today. Green credentials grow tomorrow. In an industry where rules change fast, this setup keeps you ahead.

Based in Qingdao, Shandong, Qingdao Xingfu Energy Equipment Co., Ltd. has worked in this field since 2010. They build strong industrial boilers, pressure vessels, and waste tire and plastic pyrolysis systems. With 228 employees—including 78 engineers and 65 certified welders—they produce CE- and ISO9001-certified equipment. They ship to countries from Indonesia to Spain. Over a decade, they’ve generated over 100 million RMB in domestic sales. They don’t just sell machines. They deliver the full knowledge and support that keeps clients coming back.

In the end, combining pyrolysis and distillation isn’t optional. It’s the advantage that turns waste into a real asset. This integrated approach delivers clean, standard fuel from yesterday’s tires. It closes loops that save money and protect the environment. For anyone dealing with large waste volumes, it’s worth a close look. The numbers work. The real-world stories check out. And the future starts to look a lot brighter.

What exactly does an oil distillation plant do in the waste-to-fuel process? An oil distillation plant takes the dark, thick oil from pyrolysis and separates it into usable parts—like diesel and petrol—through careful heating and cooling. A 20-ton unit typically recovers 90% of the oil. It turns tire-derived sludge into fuel that powers engines cleanly.

How does the full loop from waste tires to standard fuel actually work in a real plant? It begins with shredding tires. Then pyrolysis breaks them into raw oil and byproducts. Distillation refines that oil into high-grade diesel. Syngas from the process heats the whole system. Plants often achieve 85% overall yield. One ton of tires can produce around 400 liters of road-ready fuel. The char sells for extra income.

Is a 20-ton oil distillation plant right for smaller operations? Yes, especially if you process 10-15 tons of pyrolysis oil per week. It runs in batches, so it’s flexible for startups. Power use is low at 36 kW. Safety features like indirect heating make it reliable. Many operators start here and add continuous lines as volume grows.

What kind of environmental wins come from pairing pyrolysis with an oil distillation plant? The benefits are clear. Landfill use drops by 90%. CO2 emissions fall sharply compared to burning tires. Gases recycle on-site. Integrated setups in Europe have cut emissions by 65%. They help meet regulations while turning waste into profit.

How long until an integrated pyrolysis-distillation system pays for itself? Most often 18-24 months. At current oil prices, a 20-ton plant can generate $200K yearly from diesel sales alone. When you feed it in-house pyrolysis oil, there are no middlemen. The savings and revenue add up quickly.