Controlling energy use in semi-continuous pyrolysis plants is key for better performance and cost savings. Challenges like uneven heat spread, changing feedstock quality, and heat escape hurt efficiency. Qingdao Xingfu Energy offers smart answers. These include better methods, modern heat reuse, and clever automation. Together they cut wasted energy and boost output. This article looks at important ways to make plant work greener and more effective.

Semi-continuous pyrolysis plants mix batch and constant processes. This gives flexibility and good output speed. But this setup brings special problems that change energy use.

These systems add raw materials and remove waste at set times. Meanwhile, heat reactions keep going. This on-and-off material flow causes heat changes. Extra energy is then needed to steady reactor conditions. The start-stop way of moving materials also causes poor heat keeping and extra fuel use.

In semi-continuous plants, heat load spreads unevenly during work cycles. Top energy need happens at startup or when loading materials. This causes jumps in fuel use. Uneven heat spread weakens heat movement systems. This lowers total setup efficiency.

Energy escape usually comes from weak heat wrapping, poor burning setups, and bad exhaust gas handling. Also, unfinished pyrolysis reactions add to wasted energy. These happen when heating time or temperature control is wrong.

Qingdao Xingfu Energy knows these troubles—irregular feeding cycles, unequal heat spread, and unchecked heat loss—are main issues in semi-continuous plant work.

Boosting energy efficiency starts with improving material prep and controlling work settings across the pyrolysis process.

Good raw material prep gives steady heat take-in and even breaking down inside the reactor space.

High wetness needs hidden heat for drying before pyrolysis starts. Pre-drying materials or picking dry inputs greatly lessens this load on heating systems.

Same-sized pieces allow equal heating. They stop cold spots in the reactor. This steadiness speeds up pyrolysis reactions. It also avoids local hot spots or unfinished work.

Carefully changing work settings directly affects fuel needed to keep best reaction states.

Keeping steady heat inside the reactor stops needless reheating cycles. Modern sensors and feedback systems can adjust burner output using live heat data.

Changing heating time makes sure materials get enough exposure for full change without extra heat. This balance reduces both too little and too much work. It cuts wasteful energy use.

Qingdao Xingfu Energy handles these issues with custom answers. They improve material prep rules and sharpen control over process factors. This lowers needless fuel spending.

New advances offer real tools to shrink energy use through smarter heat use and clever system watching.

Grabbing waste heat from exhaust gases or cooling areas can greatly cut outside fuel needs.

Saved heat can warm incoming materials or air for burning systems. This reuse method gets the most heat from current work.

Specially made heat switchers with big surface areas ensure good leftover heat transfer. This happens without slowing work or risking safety.

Self-running systems allow live changes using work data. This cuts human mistakes and speeds up responses to inefficiencies.

Sensors placed throughout the setup gather heat, pressure, flow speed, and gas data non-stop. Studying this helps workers spot signs of extra energy use or poor work areas.

Forecasting tools guess equipment wear or failure before it hurts efficiency. This is vital for burners, valves, or heat switchers. Small problems here can cause big heat loss if ignored.

Qingdao Xingfu Energy adds modern technologies like clever watching setups and custom heat reuse units to their plant designs. This fights normal inefficiencies seen in older systems.

The physical setup of machines is vital to lower heat escape across the system.

A tight layout shortens pipe runs, travel time between parts, and outer exposure. All these help lower surrounding heat loss. Smart placement helps work flow and saves energy between steps.

Advanced wrapping like ceramic fiber sheets or multi-layer mirror covers hold inner heat better than old lagging ways. Good sealing at joins stops leaks that cause heat loss over time.

Qingdao Xingfu Energy stresses well-planned plant layouts with top-grade wrapping fixes. This is part of their promise to give heat-efficient work made for client needs.

Even with modern machines, human watch stays key for keeping best work levels over time.

Clear rules lower differences caused by uneven work ways across shifts or staff changes. These rules help keep steady states needed for thrifty energy use.

Teaching workers best methods—like spotting odd signs early or right shutdown/startup steps—helps them make smart choices. This protects energy savings across cycles.

Qingdao Xingfu Energy gives full teaching units focused on building plant workers’ skills. These are needed to keep high-efficiency work going steady.

Regular upkeep keeps all parts working their best without wasting power through wear or breakdowns.

Routine checks find issues like blocked burners or damaged wrapping before they become big energy wastes. Check records also show past problems that might need system changes.

Cleaning burners gives full burning; adjusting valves improves flow exactness; clearing scale from heat switchers keeps top heat movement—all key jobs for saving low-energy work standards.

Qingdao Xingfu Energy includes preventive upkeep plans in their after-sale help package. This backs lasting gains in plant efficiency through early care steps.

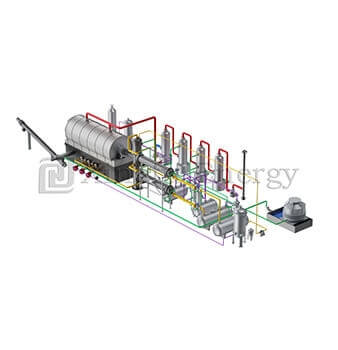

As a top pyrolysis tech provider, Qingdao Xingfu Energy focuses on creating semi-continuous plants. They strongly stress energy saving at every step—from planning to doing and support work.

With years of field know-how, Qingdao Xingfu Energy delivers custom pyrolysis setups built for top heat thrift under varied work states worldwide.

Their building team chooses tight layouts, built-in automation tools, modern wrapping stuff, exact burners, and block setups. These are shaped specially to lower fuel use while keeping output quality and safety rules.

Beyond setup, they give worker teaching programs focused on lasting ways. They also offer guess-based upkeep services made for each client’s special work profile. This ensures constant gains long after starting work.

Boosting heat thrift in semi-continuous plants needs a joined method. This involves better methods, new technologies, wise design picks—and above all—a steady helper like Qingdao Xingfu Energy. They are devoted to giving custom answers that push clear gains across all work sides.

Energy use changes based on material type and system plan. But it usually falls between 300–500 kWh per ton handled when well-tuned with reuse systems built into work.

Yes; change options include adding waste heat reuse units, bettering wrapping stuff, automating control setups, or rearranging layouts—all backed by Qingdao Xingfu Energy’s building help team when asked.

Materials with less wetness need lower drying energy; same piece size helps even heating—both big factors changing total fuel needs during work cycles.