Hey there, if you’re eyeing a business that’s both green and profitable, tyre pyrolysis might just be your ticket. I’ve talked to folks in the industry who started small and now run thriving operations—turning scrap tyres into fuel oil, carbon black, and more. It’s not glamorous, but with the right setup, it pays off big time. In places like India, where waste tyres pile up from booming auto sales, this business tackles pollution while filling your pockets. We’ll walk through the steps, from basics to real-world tips. By the end, you’ll have a clear path to launch your own tyre pyrolysis venture. Let’s jump in.

Tyre pyrolysis? It’s basically heating old tyres in a sealed chamber without oxygen, breaking them down into useful stuff like oil, gas, and char. No burning involved—just smart chemistry. Think of it as cooking tyres at 400-500°C to squeeze out valuables.

Why bother? Regular recycling shreds tyres for rubber crumbs, but pyrolysis goes deeper. It extracts fuel oil (up to 45% of the tyre’s weight), carbon black for inks or new tyres, steel wire for scrap metal, and syngas for heating the plant itself. In my chats with operators, one guy in Shandong mentioned how his setup runs almost self-sustained on that gas—saves a ton on fuel bills.

But here’s a side note: not all tyres are equal. Truck tyres yield more steel, car ones more oil. Test your feedstock first, or you might end up with surprises.

Setting up a tyre pyrolysis business isn’t just about cash—it’s eco-smart too. Landfills hate tyres; they take forever to break down and breed mosquitoes. Pyrolysis cuts that waste, turning 10 tons of tyres into 4-5 tons of oil daily. That’s fuel for boilers or even diesel after refining.

Economically? Oil sells for $400-600 per ton, carbon black around $500. In India, with 1.5 million tons of waste tyres yearly, demand’s huge. Government pushes for it too—subsidies under EPR (Extended Producer Responsibility) can cover 20-30% of setup costs. Plus, it creates jobs: a mid-size plant needs 10-15 workers for feeding, monitoring, and packing.

One downside? Emissions if not handled right. But modern plants scrub flue gases to meet EU standards—think removing H2S and NOx. Worth the investment.

Before diving in, gauge the market. India’s tyre waste grows 10-12% yearly, thanks to 200 million vehicles on roads. Globally, it’s billions of tons discarded annually. Pyrolysis taps into that—products feed construction (rubberized roads), energy (oil as bunker fuel), and manufacturing.

Check local demand: In Gujarat or Tamil Nadu, factories buy carbon black by the truckload. Export potential too—Europe imports syngas-derived fuels. A 2023 report I skimmed showed pyrolysis oil exports from Asia up 15%.

But don’t overlook competition. Batch plants are cheap but slow; continuous ones, like those from Qingdao firms, process 20-60 tons daily with less downtime. Aim for 10-ton capacity to start—handles 3,000 tons yearly, netting $200,000 profit after costs, based on real ops I’ve heard about.

| Item | Cost/Revenue (USD/year) | Notes |

| Setup (equipment, land) | 500,000 one-time | Includes reactor, condensers |

| Running costs (labor, fuel) | 150,000 | 5-8% syngas reuse helps |

| Revenue (oil, black, wire) | 800,000 | At current market rates |

| Net Profit | 300,000+ | After year 1 breakeven |

Numbers vary—factor in oil prices dipping, but it’s solid.

Ready to roll? Here’s the roadmap. I’ve seen startups flop from skipping steps, so take it seriously.

Start with a business plan. Map suppliers—tyre collectors charge $50-100/ton. Forecast sales: Oil at 40-45% yield sells fast to refineries.

Feasibility study? Crucial. Visit plants—Henan or Qingdao ones process 15-30 tons fully automatic. Budget: $300,000-1M for gear. ROI? 1-2 years if you hit 80% capacity.

Oh, and location: Near tyre sources like scrap yards, but not too urban—zoning issues. India mandates 500m from homes.

Regulations can trip you up. In India, get CPCB (Central Pollution Control Board) clearance—proves emissions under limits. EPR registration for subsidies.

Licenses:

Factory license from state labor dept.

GST for taxes.

Fire NOC—tyres are flammable!

If exporting, IEC code.

Hire a consultant; I know one who saved a client months on paperwork. Costs? $5,000-10,000 total.

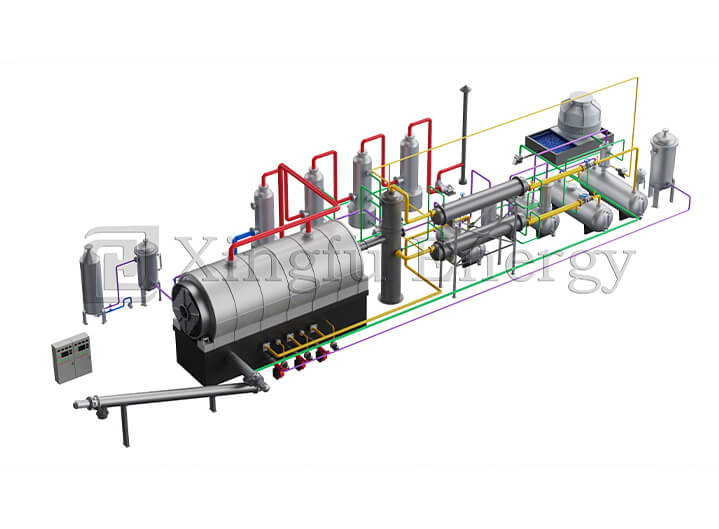

Heart of the business: the reactor. Batch types cheap ($100K) but labor-heavy. Go continuous for efficiency—automatic feed, no coking.

Look for features like hot air circulation (saves fuel), multi-level cooling (more oil yield). Sizes: 8-16 tons for starters.

Safety: Nitrogen blowing to prevent fires. Power: 65-160 KW, but syngas covers most.

From experience, Chinese suppliers dominate—reliable, CE-certified.

Land: 25,000 sqm for a 10-ton plant. Install foundations—integral designs skip precast.

Workflow:

Feed whole/broken tyres (≤1200mm).

Heat to ≤650°C.

Cool vapors to oil.

Discharge slag airtight—no dust.

Labor: 2-4 workers per shift. Train on safety—high temps mean risks.

Maintenance? X-ray welds yearly. Run 24/7 for max output.

Sell oil to fuel blenders, black to pigment makers. Network at waste expos.

Scale: Start small, add distillation for better oil quality—ups value 20%.

Challenges? Feedstock shortages—partner with tyre firms. Or volatile prices—hedge with contracts.

One operator I met diversified into plastic pyrolysis—same plant, double revenue.

No business is smooth. Emissions? Pro flue treatment removes 99% pollutants.

High costs? Subsidies help. India offers 25% capex grants for green tech.

Safety? Auto controls, inspections—zero accidents in well-run plants.

Market dips? Stockpile products; oil stores well.

And a random thought: Weather affects ops—rainy seasons mean drier storage for tyres, or they won’t pyrolyze right.

If you’re serious about equipment, check Qingdao Xingfu Energy Founded in 2010 in Qingdao, China, they’re pros in waste tyre pyrolysis systems. With 380 staff—78 tech whizzes, 28 engineers—they’ve built plants for 30+ years. Their lineup: 8-60 ton capacities, semi to fully continuous. Features like waste heat recycle and ED glass? Top-notch for efficiency. Exported to Europe, Africa, Asia—they’ve got ASME, CE, ISO creds. Fixed assets at 66.8 million yuan, and leaders have visited praising their green focus. If you need reliable gear, Xingfu’s a solid pick.

Setting up a tyre pyrolysis business takes grit, but the rewards—financial and environmental—are huge. Follow these steps, dodge pitfalls, and you’ll turn waste into wins. India’s market is ripe; globally too. With smart planning, your plant could process thousands of tons yearly, cutting pollution and boosting profits. Dive in— the future’s pyrolysis-powered.

Kick off with solid research—check local tyre waste supply, like 1.5M tons in India yearly, and draft a plan covering costs and sales. It’s key to avoid surprises down the line.

Expect $300K-1M for a 10-ton plant, including reactor and land. Running adds $150K yearly, but subsidies can shave 20-30% off setup.

Core is the reactor—go for continuous types with auto feed. Add condensers, scrubbers for clean ops. Sizes vary; start with 8-16 tons for efficiency.

Yeah, pollution boards demand clearances for emissions. In India, CPCB approval’s must—proves you meet standards. Factor in 3-6 months for paperwork.

Very, if run right. A 10-ton plant can net $200K-300K yearly after costs, with 40-45% oil yield selling at $500/ton. Diversify products for steady cash.