Atmospheric crude distillation is a key process in oil refining. It splits crude oil into different parts based on their boiling points. This happens under normal air pressure. The oil is heated to high temperatures, turning it into vapor. These vapors then cool and condense at different heights in a distillation column. This separates them into products like gasoline, kerosene, diesel, and heavier oils.

The process begins with crude oil heated in a furnace to about 350–400°C. After heating, the oil enters a distillation column. Lighter parts rise to the top. Heavier parts sink to the bottom. This separation gives each product unique traits for specific uses.

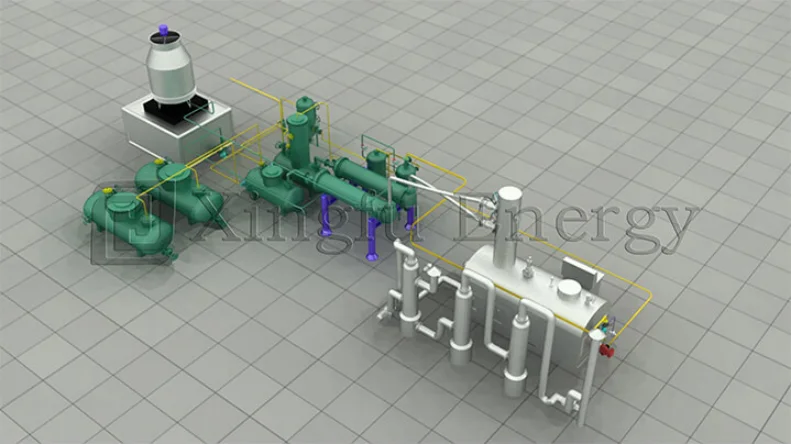

An oil distiller has several important parts that ensure proper separation of crude oil products:

Furnace: Heats crude oil to the right temperature to turn it into vapor.

Distillation Column: A tall structure where hydrocarbons split based on boiling points.

Trays or Packing Material: Inside the column, these help vapors and liquids mix for better separation.

Condensers: Cool vapors to turn them back into liquid.

Reboilers: Add extra heat at the column’s base to improve separation.

These parts work together to increase the amount and quality of products from crude oil.

Precision matters a lot in atmospheric crude distillation. Small changes in temperature or pressure can affect product quality and output. Careful control ensures products like gasoline and diesel meet industry rules. It also cuts down on waste.

Modern automation systems help by constantly checking and tweaking settings. This boosts efficiency. It also lowers energy use and environmental harm.

Inefficiencies in atmospheric crude distillation can come from many sources. Equipment wear is one cause. Poor operating conditions are another. Changes in crude oil type can also create problems. For example, dirt buildup in heat exchangers or trays can lower heat transfer. This leads to incomplete separation of products.

Energy loss is another issue. Old equipment or poor insulation can cause this. These problems raise costs. They also hurt overall output.

Operators often face issues like uneven heat in the distillation column. Sudden pressure drops are another problem. These can mess up the separation process. They may also lower product quality.

Regular checks and upkeep are vital. They help spot and fix issues early. Tools like infrared cameras or sound-based tests can find problems before they grow big.

Outside factors can affect how well an oil distiller works. Changes in crude oil makeup are one example. So are shifts in weather temperature. Heavier oils may need more heat to separate. This uses more energy.

Rules about the environment add challenges too. They set tight limits on emissions and waste. To meet these, refineries need new ideas and better tools.

A great way to control your oil distiller is by fine-tuning temperature and pressure. Exact control of these settings ensures good separation. It also saves energy.

New control systems with sensors make real-time changes based on conditions. This flexibility cuts downtime from manual fixes. It keeps the unit running smoothly.

Spending on better monitoring and automation systems improves control of your oil distiller. These systems give clear data on things like heat levels, flow speeds, and product amounts.

Automation cuts down on mistakes by keeping operations steady. For example, Qingdao Xingfu Energy Equipment Co., Ltd provides custom industrial boilers and pressure vessels. These are built to fit specific needs.

Routine upkeep is key for keeping your oil distiller reliable. Important tasks include:

Cleaning Heat Exchangers: Stops dirt buildup that blocks heat transfer.

Checking Trays/Packing Material: Ensures good mixing of vapors and liquids.

Calibrating Instruments: Keeps measurements like temperature accurate.

Replacing Worn Parts: Prevents sudden breakdowns that stop operations.

Regular maintenance extends equipment life. It also lowers costs by avoiding big repairs.

Data analytics is now a big part of improving atmospheric crude distillation. By gathering and studying real-time data from sensors, refineries can spot inefficiencies. They can also predict equipment issues and make smart choices to boost output. Tools for analytics show heat patterns, pressure changes, and flow rates in the column. This gives insights that were hard to get before.

For example, predictive analytics can warn about maintenance needs. It spots trends in how equipment performs. This reduces downtime and repair costs. Machine learning tools give tips for tweaking processes based on past and current data.

Using strong data analytics improves crude oil separation. It also helps meet environmental rules by tracking emissions and waste in real time.

New technologies are changing atmospheric crude distillation. Tools like better heat exchangers, smart control systems, and improved column designs increase efficiency and safety.

High-efficiency heat exchangers save heat from leftover streams. This cuts energy use while keeping ideal temperatures. AI-powered control systems adjust heat, pressure, and flow precisely. This ensures steady product quality.

Modular designs make distillation units easier to scale or customize. Qingdao Xingfu Energy Equipment Co., Ltd offers tailored solutions for specific needs. These upgrades streamline work and make equipment last longer by reducing wear.

Saving energy is a big goal for refineries. It lowers costs and environmental impact. Several methods can cut energy use without hurting output quality or amount.

One way is improving the preheating process with better furnaces. New furnaces use low-emission burners and good insulation. This makes them more efficient. Multi-effect evaporators can also save heat from vapor streams. This boosts energy savings.

Upgrading insulation on pipes and tanks stops heat loss during transport and storage. This directs more energy to useful tasks. Refineries can also try renewable energy, like solar heat systems, to help with heating needs. These green options support global efforts to cut carbon while keeping production strong.

Training operators is vital for the long-term success of an oil distiller. Skilled workers can manage complex systems better. They can fix problems quickly and follow best practices for efficiency.

Training should cover process improvement, safety rules, and equipment care. Hands-on workshops with classroom lessons give operators a full understanding of atmospheric crude distillation.

Encouraging ongoing learning keeps operators up to date on new tools and trends. Certification programs from industry groups boost their skills and confidence in handling advanced equipment.

The oil refining industry keeps changing. New technology and market needs drive this. Refineries must adapt to stay ahead.

One trend is making cleaner fuels with less sulfur to meet strict environmental rules. Refineries need to add desulfurization or hydrocracking to their distillation units. This helps make products that follow the rules.

Another new idea is using digital twins. These are virtual models of real systems. They let refineries test changes in a safe way before trying them for real. This cuts risks.

Working with companies like Qingdao Xingfu Energy Equipment Co., Ltd gives access to the latest solutions for atmospheric crude distillation. These partnerships make it easier to add new technology while keeping current systems working.

Data analytics helps by giving real-time details on key factors like heat patterns and pressure changes in the distillation column. This supports better choices.

New tools include high-efficiency heat exchangers, AI-powered control systems, modular designs for growth, and advanced furnaces for energy savings.

Refineries can save energy with better furnaces for preheating, improved insulation on pipes and tanks, heat recovery from evaporators, or renewable energy like solar heat.

Training helps operators run complex systems well. It improves problem-solving and safety, ensuring long-term success.

Trends include making cleaner fuels with less sulfur using desulfurization or hydrocracking and using digital twins to test changes safely before applying them.

For more details on custom solutions for your refinery, contact Qingdao Xingfu Energy Equipment Co.,Ltd ., located in Qingdao city. They specialize in innovative industrial boilers.