Oil distillation is a vital process in the petroleum and chemical sectors. It separates crude oil into different components based on their boiling points. This technique extracts valuable products. These include gasoline, diesel, kerosene, and other petrochemicals. The method works because hydrocarbons have unique boiling points. Controlled heating and condensation enable their separation.

Distillation depends on volatility. Crude oil is a mix of hydrocarbons. Each has a different molecular weight. In a distillation column, heat causes lighter hydrocarbons to vaporize first. These have lower boiling points. The vapors rise through the column. They condense into liquids at specific trays. Heavier fractions stay liquid longer. They collect at lower levels. Modern systems control temperature and pressure precisely. This improves separation efficiency.

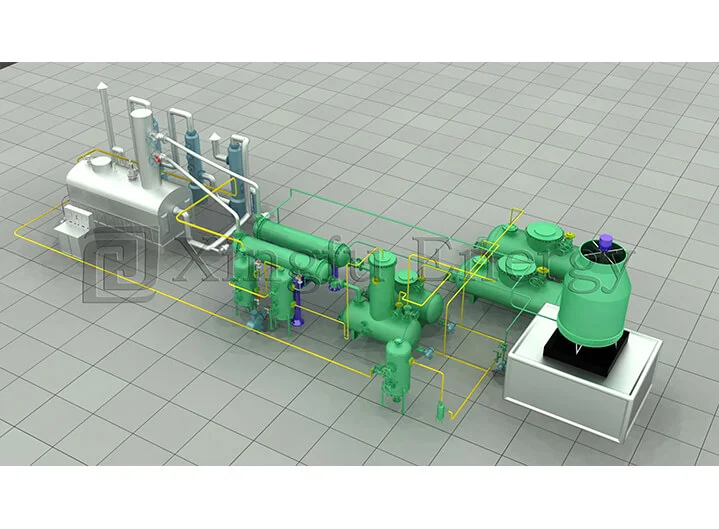

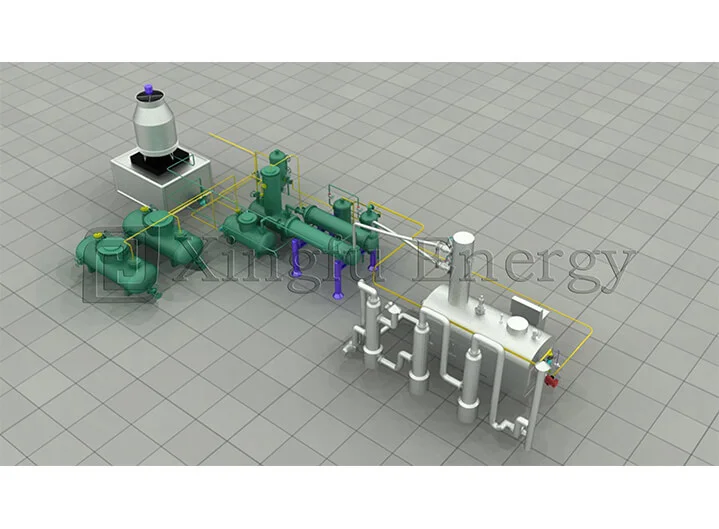

A pyrolysis plant is designed for effective oil distillation. Qingdao Xingfu Energy Equipment Co., Ltd. manufactures these plants. They include key parts. A reactor heats raw materials. A cooling system condenses vapors. Storage tanks collect distilled products. The plants use airtight high-temperature feeding systems. These reduce heat loss and ensure safety. Multilevel cooling designs boost fuel oil recovery.

Small-scale setups use compact distillation units. These are easy to install and operate. They often have semi-automatic controls. They suit smaller amounts of raw material. Large-scale plants use fully automated systems. These handle large volumes efficiently. Features like hot air heating and heat recycling lower costs. They also increase output. Both scales need strong safety systems. High temperatures and flammable materials pose risks.

Preheating: Crude oil is warmed using heat exchangers. This happens before it enters the distillation column.

Separation: Heated crude flows into the column’s base. It begins to split into fractions based on boiling points.

Vaporization: Lighter hydrocarbons turn into vapor. They rise through the column’s trays.

Condensation: Vapors cool as they ascend. They turn back into liquids at specific levels.

Collection: Products like naphtha, kerosene, diesel, and residue are gathered from different outlets.

Residue Handling: Heavy residues at the bottom may be processed further. They can also serve as feedstock for other uses.

Safety is critical in atmospheric crude distillation. High temperatures and pressures are involved. Key measures include:

Temperature Control: Automated systems monitor heat levels. They prevent overheating.

Pressure Management: Relief valves maintain safe pressure limits.

Leak Prevention: Airtight seals and regular checks stop leaks of volatile substances.

Fire Safety: Fire suppression systems tackle potential ignition risks quickly. Qingdao Xingfu Energy Equipment Co., Ltd., based in Qingdao city, offers tailored solutions for operational needs.

Pyrolysis transforms oil refining. It breaks down complex materials like waste tires and plastics. This happens through thermal decomposition. Unlike traditional methods, a pyrolysis plant operates without oxygen. This prevents burning and allows recovery of valuable byproducts. Qingdao Xingfu Energy Equipment Co., Ltd. produces advanced pyrolysis plants. These focus on efficiency and safety. They use airtight high-temperature feeding systems. This minimizes heat loss and optimizes conditions.

The process starts with raw materials entering a reactor. High temperatures cause decomposition. Products include pyrolysis oil, carbon black, and syngas. The oil can be distilled into fuels like diesel or gasoline. Carbon black is used in various industries. Syngas, a mix of hydrogen and carbon monoxide, powers the plant. This reduces operating costs.

Pyrolysis technology has many advantages. It reduces waste and recovers resources. It processes non-biodegradable materials like plastics and tires. This helps the environment and creates value. The fully automatic waste tire pyrolysis plant by Qingdao Xingfu Energy yields 40-45% fuel oil. It also produces carbon black and steel wire. This efficiency suits industries seeking green solutions.

Challenges exist. Setting up a pyrolysis plant requires a large initial investment. Financial planning is key. Consistent feedstock quality is also crucial. It ensures optimal performance. Regulations on emissions and waste management need attention. This ensures compliance with environmental standards.

Distilled oils from pyrolysis have wide industrial uses. Diesel powers heavy machinery and vehicles. It has high energy density. Refined oils are used in heating furnaces and metallurgical processes. These need steady heat. Fuel oil from pyrolysis can run industrial boilers. It can also be processed into light gas turbine fuel.

Carbon black is another byproduct. It is used in rubber products like tires and conveyor belts. Its fine particles improve strength and durability. Steel wire from tire pyrolysis is recycled. It is used in construction or automotive parts.

Distilled oils impact daily life. They are part of consumer products. Kerosene is used for cooking and lighting in many areas. Gasoline fuels vehicles worldwide. Naphtha is a feedstock for plastics and synthetic fibers.

Cosmetics also benefit. Paraffin waxes are in skincare products like creams and lip balms. Distilled oils aid pharmaceutical manufacturing. They help create active ingredients for medicines.

Environmental sustainability matters in pyrolysis operations. Emissions are a concern during processing. Modern plants use advanced technology to reduce impacts. Pulse dust removal systems cut particulate emissions during discharge. Qingdao Xingfu Energy’s designs include multilevel cooling. This improves fuel recovery and reduces environmental impact.

Syngas is another focus. It is used as an internal energy source. This prevents its release into the atmosphere. It lowers greenhouse gas emissions. It also reduces reliance on external fuels.

Sustainable practices ensure the industry’s future. Recycling waste like tires or plastics supports a circular economy. It turns potential pollutants into resources. The airtight reactors from Qingdao Xingfu Energy prevent heat loss. They maintain efficiency.

Renewable energy sources like solar or wind can be integrated. This cuts carbon footprints. Regular maintenance improves equipment performance. It also extends lifespan, reducing resource use.

A pyrolysis plant thermally breaks down organic materials. It processes plastics or tires. It produces oil, carbon black, and syngas without oxygen.

Atmospheric crude distillation separates crude oil by boiling points under normal pressure. Pyrolysis decomposes complex materials without oxygen.

Tire pyrolysis yields fuel oil (40-45%), carbon black (32-36%), steel wire (14-16%), and syngas (5-8%).

Yes, it reduces landfill waste. It recycles non-biodegradable materials. Emission control technologies are included.

For customized energy solutions, contact Qingdao Xingfu Energy Equipment Co., Ltd. Located in Qingdao city since 2010, they lead in innovative boilers and waste recycling systems.