Pyrolysis is a way to heat stuff like waste plastics or tires without air. This breaks them into smaller pieces. It makes useful things like pyrolysis oil, carbon black, and syngas. People like this method because it turns hard-to-break-down waste into stuff we can use again. It also keeps the environment cleaner.

The process starts by putting waste into a closed reactor. Then, it gets very hot, between 300°C and 700°C, depending on the plastic pyrolysis machine. Without air, the waste breaks apart. This creates liquid oil, solid carbon bits, and gases. These can be cleaned up or used to make energy.

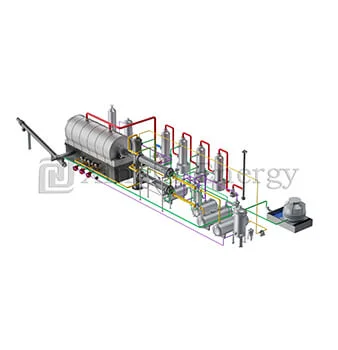

A plastic pyrolysis machine has important parts to work well:

Reactor: The main part where the waste gets broken down.

Feeding System: Puts the waste into the reactor.

Cooling System: Turns gases into liquid oil.

Gas Scrubber: Cleans the syngas before it’s used or let out.

Discharge System: Takes out solid stuff like carbon black.

Control Unit: Watches heat, pressure, and other things to keep it safe and automatic.

Plastic pyrolysis machines come in different kinds based on how they work and what they handle:

Fully Continuous Systems: These have fancy tools for non-stop work with little human help.

Semi-Automatic Systems: Need some human work but cost less for small jobs.

Batch Systems: Work in rounds and are good for small amounts of waste.

When picking a plastic pyrolysis machine, think about how much waste you need to handle. Machines come in different sizes for different amounts of waste each day. For big jobs, a continuous plastic pyrolysis machine is better because it handles lots of waste fast.

Not every plastic pyrolysis machine can handle all kinds of plastics or mixed stuff. Make sure the machine works with your waste. Some machines, like those from Qingdao Xingfu Energy, can handle mixed plastics from city trash or factory waste. A machine that works with many materials is more useful.

Machines that save energy cut costs and help the planet. Look for ones with heat-saving designs or good cooling systems. These use less energy while working. Also, pick machines with tight seals to stop bad gases from leaking out during feeding or dumping.

The way a waste management machine is made affects how safe and good it is. Machines built with strong materials and good welding last longer. They work well in hot conditions. For example, Qingdao Xingfu Energy uses special welding and X-ray checks to make sure their plants are safe.

Safety is super important when checking a plastic pyrolysis machine:

Temperature Control Systems: Stop the machine from getting too hot.

Pressure Release Valves:Keep pressure balance all the time.

Dust Removal Systems: Make sure dumping is clean with no pollution to the air.

Some new machines have auto-shutoff if something goes wrong.

Keeping a waste management machine clean and checked helps it work well for a long time. Pick one that’s easy to clean and check. Machines with fewer moving parts need less fixing and last longer.

Qingdao Xingfu Energy Equipment Co., Ltd., in Shandong province since 2010, makes special high-tech machines for factory needs.

Today’s plastic pyrolysis machines are much better because of new tech. They have auto systems that make work easier and faster. These need less human help and control the process exactly. Fully automatic machines are great because they keep going without stopping. This saves time and makes more stuff. For example, Qingdao Xingfu Energy’s fully automatic plastic pyrolysis plants get 60-85% fuel oil.

Auto systems also make things safer. They watch heat, pressure, and waste levels. If something’s wrong, they fix it fast. This stops accidents and keeps products good.

Control systems have easy screens that show what’s happening. Workers can check everything from far away and make changes to make it work better. This saves energy and money.

New tech has made waste management machines, like plastic pyrolysis systems, work better. For example, new cooling systems get more liquid oil from gases. Some use multi-step cooling to make sure it works well.

Another cool idea is reusing heat. Machines use extra heat from the process to save energy. This makes them kinder to the planet. Tight designs also stop bad gases from leaking out during feeding or dumping. This follows world rules for clean air.

Dust removal is another big step. These systems make sure solid stuff like carbon black comes out clean with no bad bits in the air. For example, Qingdao Xingfu Energy uses pulse dust removal to keep things eco-friendly.

Picking a good maker is key when buying a waste management machine like a plastic pyrolysis system. Look for companies known for making great machines. Check ones that focus on waste solutions and have lots of experience with plastic pyrolysis machines.

Read what customers say about the maker. This shows if they’re trustworthy. Also, see if they follow world quality rules. This means they make safe and good machines.

Qingdao Xingfu Energy Equipment Co., Ltd., in Shandong province since 2010, is great at making high-tech waste machines. They’re a solid pick for businesses wanting top plastic pyrolysis equipment.

When choosing a maker for your waste management machine, think about these things:

Customization Options: Make sure they can build a machine for your exact needs.

After-Sales Support: Good help after buying is important for fixing and questions.

Technology Integration: Pick makers who use the latest tech in their machines.

Safety Standards: Check that the machine follows safety rules and has things like heat control and pressure valves.

Cost-Effectiveness: Look at the price but also think about long-term savings from energy use and strong build.

A good maker gives great machines and helps keep them running well for years.

A waste management machine handles different kinds of waste. It turns them into useful stuff or energy using methods like pyrolysis.

Automation makes work faster by needing less human help. It adds safety and uses resources better.

You get fuel oil (60-85%), carbon black (10-30%), and syngas (5-10%).

A good maker gives high-quality machines, great support, and follows safety rules.

Yes, some new systems can handle mixed plastics from city trash or factory waste.

Want to know more about cool solutions? Contact Qingdao Xingfu Energy Equipment Co., Ltd.