Tire pollution comes from many places. When cars drive, tires wear down. Tiny bits of rubber and fake materials fall off. These bits turn into microplastics. They pile up in dirt, water, and air. This hurts nature. Throwing away old tires the wrong way makes things worse. So do factory processes that make tires.

Throwing tires away wrong causes big issues. Tires don’t break down easily. They take up lots of room in landfills. They can hold rainwater. This makes spots for mosquitoes to grow. Mosquitoes carry diseases. If tires catch fire or get too hot, they let out bad gases. These gases, like carbon monoxide, pollute the air. They can make people sick.

Tire pyrolysis is a way to break down stuff using heat. It happens without air. High heat turns big pieces of waste into smaller bits. This method helps manage trash like tires or plastics. It makes useful things like fuel oil, carbon black, and gas.

Tire pyrolysis is a smart fix for hard-to-recycle waste. It starts by heating trash in a closed box with no air. This stops burning. As it gets hot, the waste splits into smaller pieces. For tires, tire pyrolysis makes fuel oil (40-45%), carbon black (32-36%), steel wire (14-16%), and gas (5-8%). This cuts down on landfill trash. It also lowers pollution.

Tire pyrolysis has clear steps:

Getting Ready: Put whole or cut-up tires into a tire pyrolysis reactor.

Heating Up: Warm the reactor slowly. Keep air out to control the process.

Breaking Down: High heat makes tires split into oil, carbon black, steel wire, and gas.

Cooling and Gathering: Cool the products with special systems. Collect them safely.

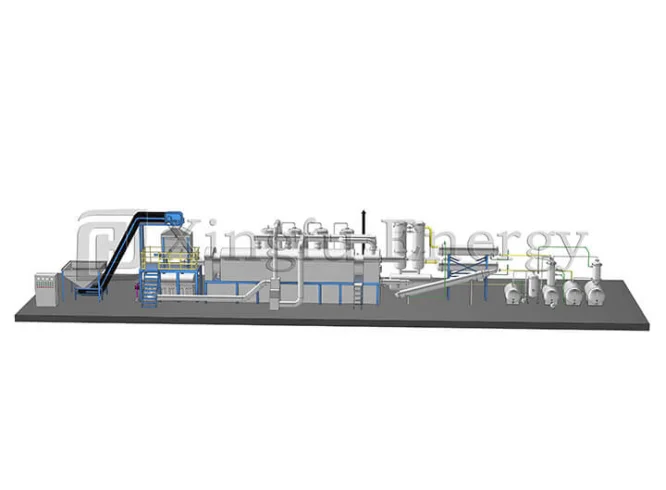

Qingdao Xingfu Energy Equipment Co., Ltd. makes top-notch tire pyrolysis systems. They focus on safety and saving the environment.

Tire pyrolysis does a lot of good:

Less Landfill Trash: It turns old tires into useful stuff. This means fewer tires in dumps.

Energy from Waste: The oil made can power factories or be turned into diesel.

Using Carbon Black: Carbon black can go into rubber products or paints.

Cleaner Air: Tire pyrolysis keeps gases in a closed system. It uses dust cleaners to cut pollution.

Tyre recycling equipment is key to tire pyrolysis. It helps break down tires and collect useful stuff. There are different types for different needs. Whole tyre pyrolysis plants don’t need tires cut up first. This saves time and work. They use layered cooling systems to get more fuel oil. They also have dust cleaners to keep the air safe. These plants are easy to run. Only 2-3 workers are needed. Broken tyre pyrolysis plants work with cut-up tires. They have tight seals for hot feeding. This saves heat and time. They use hot air and smart heat-saving designs to cut costs.

Tyre recycling equipment is getting better. New tech makes it safer and greener. Fully automatic tire pyrolysis plants use strong welding and X-ray checks. This makes them tough and safe. Layered cooling systems grab more fuel oil. They also cut down on bad gases. These changes boost work speed. They also meet strict clean-air rules.

Tire pyrolysis gives useful products:

Fuel Oil: This makes up 40-45% of the output. It’s used in factories or can be made into diesel.

Carbon Black: This is 32-36% of the yield. It’s used in rubber, paints, or as a filler in products.

Steel Wire: This is 14-16% of the output. It’s recycled for building or new steel items.

These products show tire pyrolysis is a money-smart way to handle trash.

The stuff from tire pyrolysis is used in many ways:

Fuel Oil: Powers factory furnaces, metal work, or becomes diesel.

Carbon Black: Goes into making tires, belts, hoses, inks, paints, or batteries.

Steel Wire: Gets reused in building or as raw material for steel.

These uses help the planet. They also create jobs by turning waste into sellable goods.

Growing tire pyrolysis has some hurdles:

Big Starting Costs: Setting up a tire pyrolysis plant costs a lot. You need money for tyre recycling equipment and setup.

Running Costs: Energy and upkeep can be pricey.

Skilled Workers: Running high-tech equipment needs trained people.

But there are ways to fix these. Government help, team-ups with companies, and new tech can lower costs. They can also make things run smoother.

Tire pyrolysis has a bright future. New ideas are making it better. Scientists are working on faster reactors and better cooling systems. Automation is helping too. Using clean energy, like solar, can make plants greener. As people care more about trash problems, tire pyrolysis will be a big part of reusing waste well.

Whole tyre pyrolysis plants and broken tyre systems process old tires well.

You get fuel oil (40-45%), carbon black (32-36%), steel wire (14-16%), and gas (5-8%).

It gives fuel oil for energy, carbon black for products, and steel wire for building.

High startup costs, running expenses, and the need for skilled workers are big issues.

For custom solutions or questions about high-tech tire pyrolysis systems, Qingdao Xingfu Energy Equipment Co., Ltd., in Qingdao City, has been building top recycling equipment since 2010.