The worldwide plastic waste crisis urgently demands creative answers. We must turn pollution into useful resources. Pyrolysis technology now stands out as a practical method. It changes non-recyclable plastics into fuel oil, carbon black, and syngas. This supports a circular economy. Our article examines how pyrolysis plants tackle plastic waste issues. It also covers their environmental gains. Plus, we look at the improvements boosting their performance. Top suppliers, including Qingdao Xingfu Energy, deliver modern pyrolysis systems. These provide adaptable, earth-friendly waste management options globally.

Plastic production has exploded worldwide. This surge causes huge piles of plastic trash. Existing waste systems struggle to cope. We urgently need fresh ideas. Pyrolysis technology offers real hope. It turns tricky plastics into valuable items. This fits perfectly with circular economy goals.

People now consume more plastic than ever. Products also have shorter lives. Together, these factors create mountains of waste. Old recycling ways cannot handle the load. Too much trash ends up buried or in oceans. Current setups show serious weaknesses. We require scalable choices. Good options must pull value from messy, dirty plastic mixes.

Burning and burying dominate disposal today. Sadly, both harm our planet. Incineration sends out greenhouse gases. It also releases dangerous poisons. Landfilling eats up precious land space. Plus, it risks long-term leaks that poison water. Mechanical recycling has its own problems. Contamination often ruins it. Different plastics don’t always work together. Sometimes, it just costs too much.

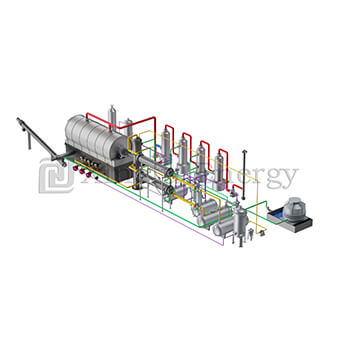

Pyrolysis provides a heat-based path. It changes waste plastics into usable fuels and materials. Crucially, it does this without burning anything. The method breaks down polymers into simpler hydrocarbons. This means we recover resources from plastics that recycling rejects. Such progress matches circular economy aims perfectly. Trash becomes fresh material for new goods. Qingdao Xingfu Energy builds fully automatic plastic pyrolysis plants. These units handle mixed plastics from homes and factories. That makes them ideal for solving old disposal problems.

Pyrolysis works without oxygen. High heat breaks things down. Complex polymers decompose into simpler parts. Then we gather fuel oil, gas, or solid leftovers.

Long polymer chains crack under thermal stress. Heat causes endothermic reactions. Oxygen stays out to prevent burning. That keeps energy locked inside the new molecules. Temperature control matters greatly. It decides how much oil, gas, or char forms.

Qingdao Xingfu Energy reports clear results. Their fully automatic plastic pyrolysis plant delivers well. It makes fuel oil at 60–85%. Carbon black comes out at 10–30%. Syngas appears at 5–10%. These outputs serve many purposes. Factories can burn fuel oil directly. Or they can refine it further. Rubber makers need carbon black. Syngas often powers the pyrolysis unit itself. Qingdao Xingfu Energy’s gear uses smart cooling. Multiple cooling stages grab more oil. Their high-temperature feeding seals tightly. This design keeps precious heat inside.

Beyond recovering resources, pyrolysis solves other environmental headaches. It fixes issues tied to old plastic disposal methods.

Burning plastic releases CO₂ and toxins straight into the air. Pyrolysis works differently. It traps emissions inside closed loops. Syngas can fuel the process itself. That cuts outside energy needs.

Pyrolysis avoids burying waste. Instead, it makes useful products. This shrinks land occupation dramatically. Buried plastics can leak nasty liquids. Those poisons threaten groundwater. Pyrolysis stops this risk completely.

Fuels from pyrolysis show cleaner lifecycles. Especially when made from waste inputs. They beat regular fossil fuels on emissions. Recovered carbon black helps too. It replaces brand-new material production. Making virgin carbon black gulps huge energy.

Qingdao Xingfu Energy’s plants include smart features. Pulse dust removal works during discharge. This keeps things dust-free. They heat using hot air systems. Clever heat recycling cuts costs. It also boosts planet protection.

Constant upgrades are vital. They lift product quality, process speed, and eco-compliance.

New reactors spread heat evenly. They transfer warmth better than old models. Automation slashes labor needs. Real-time watching improves safety greatly.

Some plants borrow green power. Solar thermal or biomass heat starts reactors. This lessens fossil fuel use overall.

Catalysts are game-changers. They lower reaction temperatures. They also help target wanted hydrocarbons. Diesel-range fuels become easier. So do petrochemical aromatics.

Qingdao Xingfu Energy chooses strong welding methods. They use submerged arc welding checked by x-rays. This ensures plant safety stays high. Operations stay efficient too. Each unit needs just 2–3 workers.

Markets now favor decarbonization and smart resource use. Pyrolysis economics look brighter. Technology matures and policies help.

Pyrolytic oil finds eager buyers. It replaces industrial fuel or crude oil inputs. Especially as crude prices climb. Carbon black sells steadily. Tire makers rely on it for color and strength.

Mechanical recycling wants clean, sorted streams. That costs money and time. Qingdao Xingfu Energy’s equipment handles mixed city waste plastics. Less sorting means lower costs. Outputs like diesel-grade oils hold higher value. Their distillation units make this possible.

Many places offer sweeteners now. Subsidies or carbon credits encourage progress. They reward landfill reduction and fossil fuel replacement. This shortens payback times for pyrolysis projects worldwide.

Qingdao Xingfu Energy holds important papers. AAA credit rating certificates show trust. Environmental product usage approvals prove compliance. These documents unlock government support programs.

Great promise exists, yet hurdles remain. Some are practical, others systemic.

Dirty inputs cause trouble. PVC plastic releases harmful gases when heated. Pre-sorting becomes essential. Sadly, many areas lack good sorting setups. Investment lags behind need.

Rules vary wildly place to place. Is pyrolytic oil “waste” or a “product”? This label changes everything. Licensing gets messy. Market access suffers.

People sometimes confuse pyrolysis with burning trash. Wrong ideas stick around. We need strong education drives. Communities and investors must grasp the closed-loop benefits clearly.

Qingdao Xingfu Energy offers flexible choices. Semi-automatic models suit different rules. Their after-sales help includes training. This smoothes adoption, even in new markets.

Qingdao Xingfu Energy Equipment Co., Ltd brings deep engineering skill. For decades, they’ve focused on sustainable energy shifts. They make top-tier fully automatic plastic pyrolysis plants. These handle varied feedstocks cleanly under strict green rules.

Their gear boasts smart designs. Airtight high-temperature feeding saves heat. Multilevel cooling grabs more oil. Pulse dust removal ensures clean exits. Together, these deliver strong performance seen globally.

Xingfu’s work spans continents. Plants run at city waste centers. Results prove reliable: 60–85% fuel oil from plastic. Clients praise easy operation. Minimal staff manage everything. Modular builds speed up starting.

The company pushes research hard. They explore better catalysts actively. Compliance matters too. Licenses like China’s Environmental Product Usage Certification show this. Back-up service stays strong after sales.

Pyrolysis changes the game on plastic waste. It converts trash into treasure through earth-kind processes. Policies keep evolving. Technology keeps advancing. Firms like Qingdao Xingfu Energy lead the charge. They supply dependable ready-to-run answers. These blend technical smarts with money sense.

Most plastics work, except PVC. Polyethylene (PE), polypropylene (PP), and polystyrene (PS) are common feeds. The exact mix depends on the reactor setup.

Sometimes yes, sometimes no. Pyrolytic oil might need cleaning up. Distillation or blending could be required for engines. Often it swaps straight into furnaces. Qingdao Xingfu Energy also sells special oil distillation units.

Run right with sealed systems, it’s far cleaner. It releases fewer pollutants than burning trash. Plus, it recovers materials. This helps nature and supports circular economies smartly.