Batch pyrolysis setups need strong mechanical and heating parts for efficient waste change. Knowing these main pieces—from the reactor vessel to sealing systems—helps workers keep things working best and stop early damage.

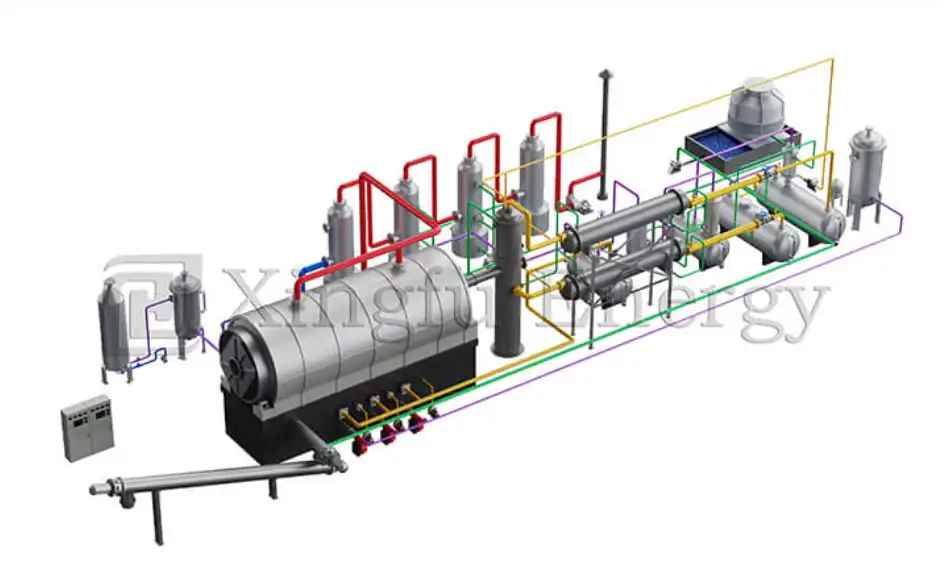

Batch type pyrolysis equipment is made of strong mechanical structures built to handle high heat and chemical reactions. The main piece is the reactor vessel, where the thermal breaking down happens. Look for signs of cracks, rust, or material wearing away. Pay special attention to areas near heating elements and places touching very hot materials. Other building parts include feed systems, outlets for removing material, support frames, and insulation layers that keep heat steady.

The heating system is vital for keeping the best pyrolytic conditions. Heating elements must spread heat evenly to make sure feedstock changes well into oil, gas, and char. Sealing systems—like gaskets and flanges—are equally key. They keep an airtight space. Check seals and gaskets often for damage or leaks. These parts make sure the airtight space needed for pyrolysis stays and stop dangerous gas leaks.

Modern batch pyrolysis systems have PLC (Programmable Logic Controller) units. These automate temperature, pressure, and timing controls. Make sure these systems get regular software updates and working checks to keep them dependable. Temperature sensors and pressure gauges give real-time information needed for safe running.

Xingfu Energy provides complete systems with advanced control units and explosion-proof parts to boost safety during high-heat tasks.

Active upkeep is vital for keeping pyrolysis efficiency. By fixing wear early and sticking to planned inspections, workers can reduce downtime, use energy best, and make the system work longer.

Preventive upkeep makes sure small problems are fixed before they become big failures. Routine inspections should be done with the right safety gear. This is because some spots might keep leftover heat or reactive stuff. This active way boosts working time and cuts emergency stops.

Over time, heat cycles cause material tiredness in reactors, pipes, and seals. Blockages can harm pressure levels and slow the flow of byproducts. These problems not only lower output quality but also make energy use higher.

Changing worn parts like valves, actuators, or insulation layers on time stops chain reactions of failure. Log each part change, including when it was put in, who supplied it, and warranty details.

Xingfu Energy stresses preventive upkeep by giving detailed papers with each unit. These help track part life and find the best times for changes.

Outside things like temperature, wetness, and dirt matter a lot for pyrolysis equipment. Good environmental control cuts rust risks and keeps heat efficiency steady during waste handling.

Very hot or cold air can strain building parts. High wetness speeds up rust on metal surfaces. Keeping a controlled space around the equipment helps save its condition.

Dust gathering on mechanical parts can cause overheating or rubbing wear. Char and ash leftovers can block heat spread and lower the reactor’s efficiency. Good dust handling plans include using pulse dust removal systems during removal steps. Xingfu Energy’s batch pyrolysis plants use airtight feeding/removal designs. These lower environmental dirt risks during use.

Using organized cleaning, oiling, and watching routines saves key parts. Long-term plans, like rust stopping and timely part changes, further boost strength and safety.

Organized upkeep routines, from reactor cleaning to oiling, make sure smooth running and reduce early wear.

Manual or automatic scraping can stop these leftovers from causing issues. Cleaning should be done after each cycle to take char leftovers off the inside walls.

Oil gears and moving parts to stop jamming and uneven feeding. Use high-heat oils made just for factory uses.

Check sensors and gauges often. Correct readings are key for the process. Any mistake in calibration could lead to wasted energy or possible safety dangers.

Using rust-proof materials and planned part improvements make the system tougher over time.

Put on anti-rust coverings or use stainless steel mixes in high-risk spots touched by condensates or acid gases.

Set change times for specific parts based on use hours or heat cycles written in upkeep records.

Xingfu Energy helps long-term strength through design improvements. These include explosion-proof wiring systems, many-level cooling circuits, and rust-proof materials in key areas.

Ignoring upkeep leads to expensive breakdowns, lower output quality, and safety dangers. Regular checks stop leftover buildup, gas leaks, and poor heat move that weaken the system.

Sudden breakdowns often come from ignored wear signs like seal leaks or uneven heating. This causes costly fixes that could have been avoided with regular checks.

Cleaning out these leftovers after each batch helps keep heat move best. When ignored, leftover buildup lowers the amount of fuel oil or carbon black made. This happens because heat move is inefficient.

Gas leaks caused by bad gaskets bring explosion risks if not checked. Put in gas sensors to watch for possible leaks.

Xingfu Energy adds many safety backups. These include emergency shutoff valves made to turn on during strange pressure jumps.

Making upkeep plans fit how much the equipment is used and using guessing tools makes sure fixes happen on time. Trained people and digital watching further smooth upkeep for unbroken running.

High-use tasks need shorter check times compared to now-and-then uses. Make your plan fit how often batches run.

Add sensor-based watching to digital dashboards. These give alerts when things go outside set levels.

Teach people emergency steps and do regular safety drills. This makes sure they act fast if dangers happen.

Xingfu Energy offers full worker training after setup. They also give technical help all through the equipment’s life.

Picking high-heat-proof materials and OEM-certified parts guarantees fit and performance. Good extra parts lower failure risks and match maker specs.

OEM parts promise fit but may cost more. Non-OEM parts might save money but risk performance issues if makers don’t approve them.

Use mixes like Inconel or stainless steel types. These can keep their condition under long contact above 400°C, often met during pyrolysis cycles. Xingfu Energy gives approved OEM extra parts made just for their batch pyrolysis models. This keeps performance steady over long use times.

Xingfu Energy mixes advanced engineering, strict quality checks, and full support work. Their equipment designs put safety, efficiency, and easy upkeep first for long-term dependability.

Xingfu Energy is a pyrolysis plant, oil distillation equipment maker. Their product list includes whole tyre pyrolysis plants needing no pre-cutting. This makes work smoother while cutting labor costs.

They use fully automatic submerged arc welding and x-ray checks. This makes the plant safer. Each unit goes through tough quality checks before shipping.

Simple to run, high efficiency; 2-3 workers can run it. Xingfu Energy backs every setup with technical paper help and worker training on-site.

A well-kept batch type pyrolysis system makes sure output amount and quality are best. It also lowers working risks all through its life. By using organized upkeep routines—from daily cleaning jobs to long-term part changes—workers can make working time longest. They also keep output quality rules key in waste-to-energy changes.

Daily look-overs mixed with weekly cleaning are suggested. Full system checks should happen monthly, depending on how much it’s used.

Yes—leftover buildup or uneven heating changes oil purity straight away. It does this by changing reaction conditions inside the reactor.

Watch temperature/pressure changes through control panels. Physical signs like gasket wear or valve stiffness also show failure risk needs part change soon.