In the recycling sector, transforming waste into valuable resources demands rigorous effort. It also calls for strategic decision-making. With mounting volumes of scrap tires and increasingly stringent environmental regulations, each discarded tire represents a potential liability for businesses. Yet, through intelligent processing, these tires can evolve into reliable revenue streams. Continuous tire pyrolysis equipment serves as a pivotal tool in achieving this shift. It enables high-volume waste handling. At the same time, it streamlines daily operations. This minimizes downtime and elevates efficiency. For business leaders seeking sustainable growth, understanding the mechanics of continuous tire pyrolysis systems is essential. So is grasping their impact on profitability.

Pyrolysis involves the thermal decomposition of tires and similar materials in an oxygen-free environment. It yields valuable byproducts via controlled heating. Unlike batch systems that require shutdowns for loading and unloading, continuous equipment operates without interruption. Raw materials enter at one end. Products emerge from the other. This fosters a steady rhythm that reduces labor requirements. It also boosts throughput.

Case Example: Consider a mid-sized facility in the Midwest. There, manual feeding previously disrupted production every eight hours. Transitioning to a continuous system smoothed the entire workflow. Shredded tires feed directly into the pyrolysis unit. They convert into pyrolysis oil, carbon black, steel wire, and syngas. The absence of pauses ensures predictable operations. These are low-effort ones, too.

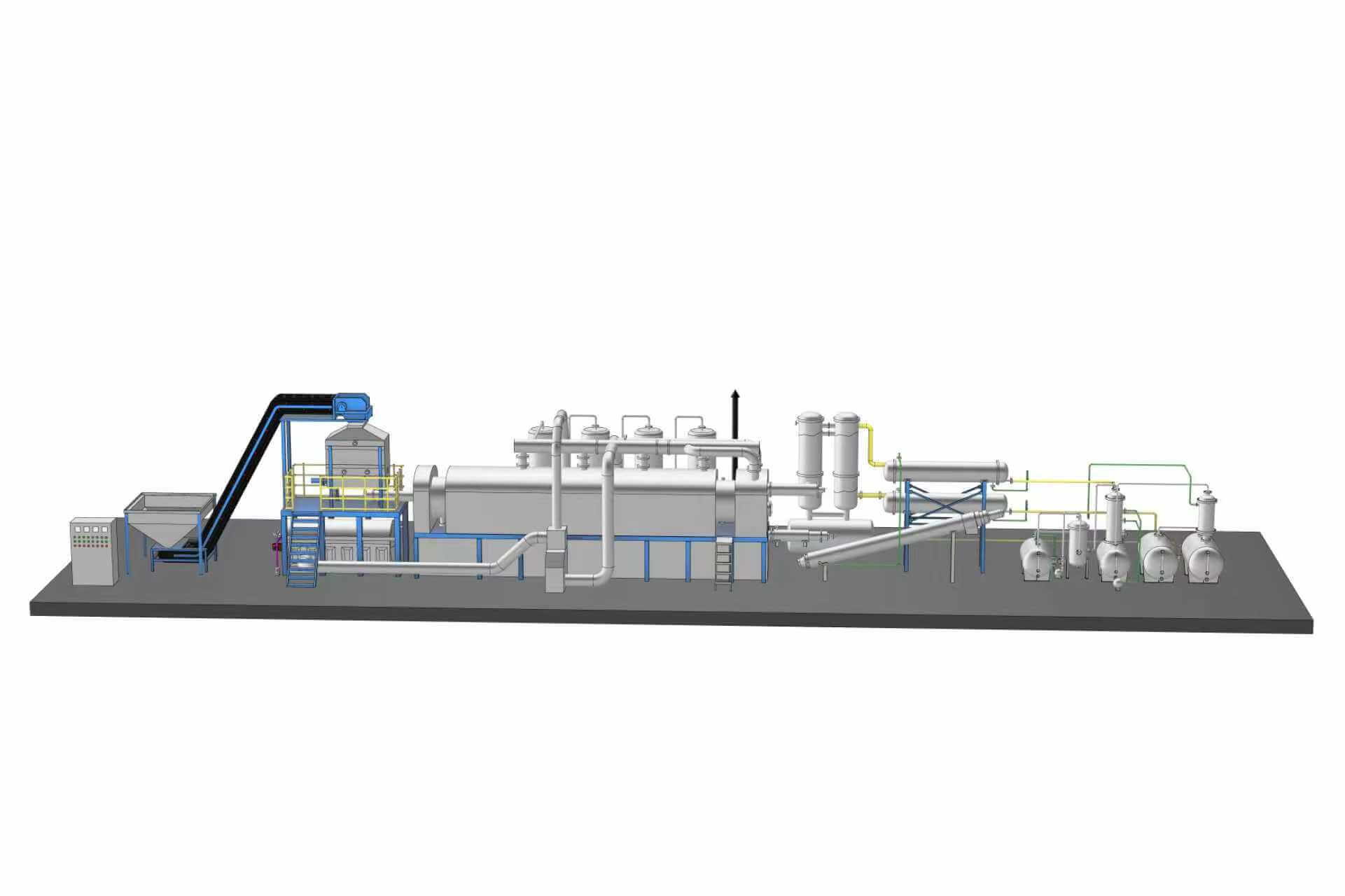

A high-performing continuous tire pyrolysis system relies on the seamless integration of several critical components.

Performance Impact: In a 15-ton-per-day unit, an anti-coking reactor design makes a big difference. Maintenance intervals extend from 24 to 72 hours. As a result, this unlocks additional production capacity. Operators appreciate the extra breathing room it provides.

Seamless execution translates to every saved minute and reduced expense. Continuous systems excel in automating the handling of coarse feedstocks. Shredded tires travel via conveyor belts into the unit. They reach a consistent 650°F near the heater. There, they decompose into distinct outputs. Operators monitor via intuitive interfaces. They make adjustments without halting the line. This keeps things moving without unnecessary hitches.

Staffing Efficiency: A typical batch station might require four workers per shift for unloading and cleaning. In contrast, continuous setups often need just one or two to oversee the full line. This frees personnel for maintenance or sales activities. Ultimately, it amplifies overall productivity. Teams find they have more bandwidth for the tasks that matter most.

Results: A Texas facility reported a 30% reduction in cycle times after installing continuous equipment. They increased monthly throughput from 300 to 450 tons. And they did this without expanding staff. The change felt like a game-changer for the crew on the ground.

Profitability hinges on the ratio of outputs to inputs. Continuous tire pyrolysis outperforms batch systems in yield consistency. Typical returns per ton of tires include 45-50% fuel oil. This is suitable for on-site heating or refining into diesel feedstock. Then there’s 32-36% carbon black for rubber compounding. Add 2-14% steel wire for straightforward recycling. Finally, 3-5% syngas serves internal use. These figures add up quickly in real-world scenarios.

Typical Outputs for a 15-Ton-Per-Day System:

| Byproduct | Yield (% per Ton) | Potential Application |

| Fuel Oil | 45-50 | Heating fuel or diesel refining |

| Carbon Black | 32-36 | Rubber additives or industrial filler |

| Steel Wire | 2-14 | Metal recycling |

| Syngas | 3-5 | On-site energy generation |

Case Insight: One operator recouped their loan in the first year through 45% oil yields. Carbon black sales provided supplementary income. It was a straightforward path to positive cash flow, and it built momentum for further investments.

While upfront investments are substantial, returns materialize quickly. A 15-ton continuous system may cost around $500,000 to install. But offsetting savings are significant. They build over time and compound nicely.

Outcomes: A Midwestern trucking firm calculated annual savings of $120,000 in disposal fees. They added $250,000 in byproduct revenue. Payback came in under 18 months. For them, it wasn’t just about breaking even—it was about freeing up capital for growth.

Multistage gas purification aligns with European emission standards. It sidesteps penalties common in batch operations. In regions with rigorous regulations, this compliance not only cuts costs. It also confers a competitive edge. Businesses stand out when they check these boxes without extra hassle.

Continuous systems scale effortlessly without major overhauls. They expand from 10 to 30 tons per day. Their compact footprint—typically 36 m x 8 m for larger models—supports modular growth. This flexibility lets operators adapt to demand swings.

Case Example: A Southeastern hub doubled capacity during peak seasons. They incorporated new revenue streams like refined oil sales. The upgrade happened with minimal disruption, and it opened doors to bigger contracts.

Poland Case: A 20-ton continuous unit processes urban scrap tires. It handles 600 tons every three months. Yields hit 270 tons of oil at a 42% rate. Startup fuel of 200 kg per cycle gave way to full syngas self-sufficiency by month six. Costs slashed by 40%. Revenue reached $180,000. That included $200,000 from exported waste oil to Germany. The numbers spoke for themselves, and the operation ran like clockwork.

U.S. Case: An Indonesian operation blended rubber scraps with tires in a 15-ton system. It was equipped with layered condensers. They achieved 48% oil recovery. With just two operators per shift, the setup recouped costs in 14 months. Now, they’re paving the way for line expansions. It’s a solid example of how these systems deliver on promises.

With over a decade of expertise in pyrolysis, Qingdao-based Xingfu Energy stands out. As a high-tech enterprise, it merges robust R&D with innovative designs for waste tire processing. Models like the 15T and 30T continuous systems prioritize reliability. They feature anti-coking reactors and syngas self-fueling loops for uninterrupted operations. Exported to more than 30 countries, sales exceed $100 million. The company delivers turnkey solutions that minimize downtime. Certifications including CE and ISO9001 underscore its quality commitment. This ensures equipment not only enhances profitability. It also advances global sustainability goals. Partners value the support that goes beyond the sale.

Deploying a continuous tire pyrolysis system converts waste into substantial wealth. It operates with reliability, efficiency, and cost discipline. These deliver tangible returns. Businesses adopting this technology meet environmental mandates. They thrive in the circular economy, too. Evidence underscores faster recovery and steady cash flow. There’s expansion potential as well. As tire stockpiles grow and margins tighten, such equipment merits close evaluation. It could be the edge your operation needs right now.

Continuous units surpass batch modes through uninterrupted operation. They reduce labor to 1-2 per shift. Daily capacity elevates to 15-30 tons. Syngas recycling eliminates fuel costs post-startup. Yields of 45-50% oil fetch over $300 per ton. This shortens ROI timelines considerably.

The system leverages hot air circulation and syngas self-combustion. It requires 200-400 kg of fuel only for initial ignition. For a 15-ton unit, power stays around 80 kW. Multistage condensers boost vapor capture by 40%. This enhances overall energy utilization across the board.

Yes, these systems adeptly process tire-plastic blends with feedstocks under 20 mm. This ensures uniform flow. Consistent outputs—32-36% carbon black and 2-14% steel wire—unlock diverse revenue channels. It broadens options without complicating things.

Emphasize enclosed designs to contain dust. Use nitrogen purging for safe startups. Routine reactor rotation prevents coking. This projects a 10-year service life. A 2-3 person team with swift condenser inspections cuts interventions by 20%. It sustains long-term profitability effectively.

Payback varies by scale. But a 20-ton facility typically recovers via over $250,000 in annual outputs. Low operating costs help, too. This happens within 14-24 months. Disposal fee offsets cover 30% of expenses. Oil and carbon black sales fuel the balance. It’s a reliable trajectory for most setups.