Waste tires and plastics pile up everywhere these days. Landfills groan under the load. Incineration pumps out nasty emissions. Recycling operations struggle with high costs and inconsistent output. Plant managers and waste processors know the drill—sky-high disposal fees, tough environmental regs, and batch systems that sit idle half the time. It’s a real headache.

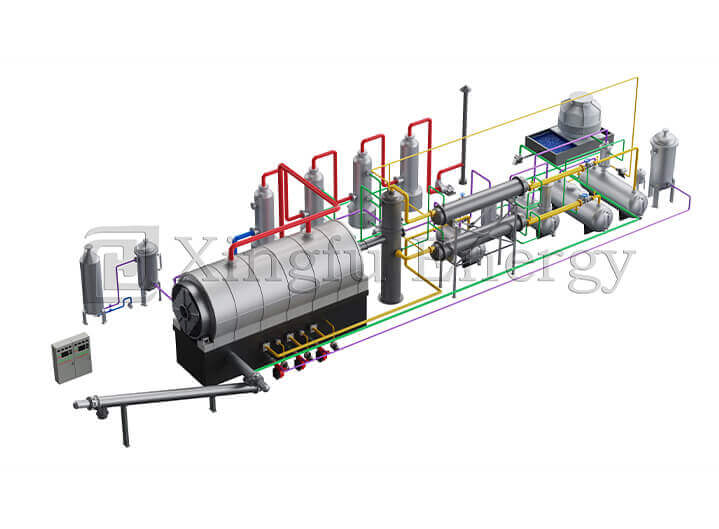

Enter the semi continuous pyrolysis plant. Specifically, the 20T models. They bridge the gap between old-school batch setups and full-blown continuous lines. You get higher throughput without the massive upfront complexity. Operators around the world are turning to these for turning scrap into fuel oil, carbon black, and steel wire. And the results speak for themselves.

This piece dives into real-world stories. We’ll look at how these 20T semi-continuous plants tackle common pain points head-on. Think lower running costs, quicker setups, cleaner operations, and solid oil yields.

Folks in the waste-to-energy game face a bunch of issues.

Batch plants? They work fine for small scales. But you feed, heat, cool, discharge—then repeat. Downtime adds up. Efficiency dips. Labor costs climb.

Full continuous systems shine for huge volumes. Yet they demand big investments, complex automation, and perfect feedstock prep. Not every site can handle that.

Then there’s the environment. Dust from feeding and discharging. High fuel bills for heating. Uneven heat leading to low oil recovery.

Disposal costs eat profits. Regulations tighten on emissions and waste handling. Investors hesitate when payback looks fuzzy.

The 20T semi-continuous design hits the sweet spot. It processes around 20 tons per day. Feeding and discharging happen more frequently without full stops. You keep the reactor hot longer. Output stays steady.

These plants handle tire shreds or plastic flakes up to 50mm. No fancy pre-processing needed beyond basic shredding.

A big draw? Quick installation. No need for a pre-cast concrete foundation. The whole unit arrives integrated. Set it on flat ground, hook up utilities, and you’re running in weeks—not months.

Real numbers back this up. Oil yield: 40-45%. Carbon black: 32-36%. Steel wire: 14-16%. That translates to serious revenue from a single day’s feed.

Operators across continents have put these 20T semi-continuous plants to work. Here’s a closer look at a few.

One setup in Mexico features dual 10T reactors running semi-continuous for a combined 20T capacity. They added an upgraded electrical system and syn gas treatment.

The site handles local tire scrap. Quick install—no foundation delays—got them operational fast. Sealed systems kept dust down in a busy industrial area. Hot air heating and gas recycling slashed fuel costs. Operators report steady 42% oil yields. Carbon black sells locally for reinforcement. Payback started looking good within the first year.

Similar 20T configs have gone live in Asia and Europe. In Malaysia, a factory-based unit processes mixed plastics and tires. Multi-level cooling pushed oil output higher than expected.

Plants in Spain and Bulgaria run sister models, often with conveyor feeds for easier loading. Across these sites, common feedback: Low labor needs—just 3-4 workers per shift. Uptime stays high thanks to even heating and no coking issues.

One European operator shared how the airtight discharge ended their dust complaints from neighbors. Another in Asia noted the energy savings covered most monthly expenses.

These aren’t one-offs. Dozens of 20T semi-continuous plants now hum along worldwide, turning waste streams into steady income.

| Aspect | Batch Plants | 20T Semi-Continuous | Full Continuous |

| Daily Capacity | 10-20T, with downtime | 20T steady | 30T+ |

| Installation Time | Months (foundation needed) | Weeks (no foundation) | Months+ |

| Labor Requirement | 5-6 people | 3-4 people | 4-5, high automation |

| Oil Yield | 35-40% | 40-45% | 45%+ |

| Energy Use | Higher external fuel | Mostly self-sufficient | Very low |

| Best For | Small operations | Mid-scale, flexible sites | Large industrial |

The semi-continuous column wins for many mid-sized recyclers. Balanced cost, output, and ease.

These plants clean up more than just waste. Sealed processes mean minimal emissions. Syn gas desulfurization keeps air clean. No open burning.

Economically? Fuel oil sells as alternative bunker or feeds distillation. Carbon black goes to rubber goods. Steel wire to scrap yards.

A typical 20T plant pays back in 2-3 years at current scrap prices. Lower energy and labor seal the deal.

Qingdao Xingfu Energy, based in Qingdao City, Shandong Province, has been a solid player since 2010. They supply industrial boilers, pressure vessels, and pyrolysis systems for waste tires, plastics, and more. With a big team of engineers and skilled welders, plus certifications like CE and ISO9001, they’ve shipped reliable gear to over 30 countries. Hands-on experience drives their practical designs.

The shift to 20T semi-continuous pyrolysis plants isn’t hype—it’s happening on the ground. From Mexico to Malaysia, these setups deliver steady runs, high oil recovery, and real cost cuts. They solve the big headaches: inefficient batch cycles, heavy install burdens, dust issues, and spotty energy use. For waste processors ready to turn liabilities into assets, semi-continuous tech offers a proven, balanced path forward.

Semi-continuous plants keep the reactor hotter longer with more frequent feeding and discharging. That boosts daily output and efficiency without the full complexity of continuous lines.

You can expect 40-45% fuel oil from waste tires or plastics, thanks to multi-level cooling and even heating.

It spreads heat evenly, cuts fuel needs, and lets you recycle syn gas—dropping operating costs way down.

Yeah, no pre-cast foundation means you set up in weeks. Perfect for getting online quick.

Absolutely. Fully sealed feeding and discharge stop dust. Gas cleaning and recycling keep emissions low.