Dealing with oily waste from drilling or refining? It’s a headache. Piles up fast, harms the land, and costs a bundle to handle. Oil sludge pyrolysis changes that. Heat it up without air, and you break it down into useful bits. No more dumping headaches. This method turns trouble into treasure. If you’re in energy or waste management, it’s worth a look. We’ll walk through what it does, why it pays off, and how it fits your setup. By the end, you’ll see clear paths to cleaner ops and better returns.

Oil sludge is that sticky mix from oil fields or tanks. Full of hydrocarbons, water, and solids. Pyrolysis heats it in a sealed spot, no oxygen. Breaks long chains into shorter ones. Gases, oils, and char come out.

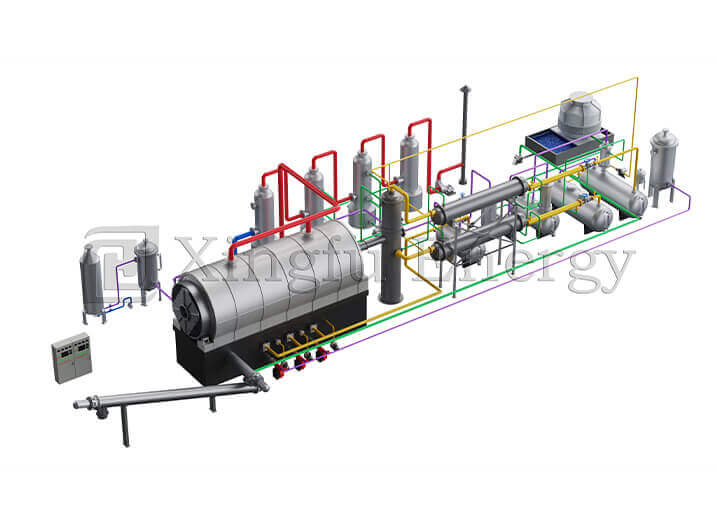

Start with prep. Dry the sludge a bit, shred if clumpy. Feed it into the reactor. Temps hit 400-600°C. Hold steady for hours. Vapors rise, cool in condensers. Liquid oil collects. Gases fuel the heat or burn clean. Solids stay as char.

No flames. Just controlled cook. Ends with safe leftovers. Takes a day for batches, less for continuous runs.

Watch the flow. Good seals keep air out. Sensors track heat. Simple tweaks keep it smooth.

Sludge builds quick in oil work. One spill equals tons. Bury it? Fines mount. Burn it open? Smoke chokes the air.

Pyrolysis fits tight. Handles wet or dry mixes. Pulls 70-80% as oil back. Beats hauling to dumps.

In spots like the Middle East or Texas, it’s a game changer. Cuts cleanup crews, speeds restarts.

Green cred matters now. Pyrolysis delivers big here. Less mess, more reuse.

Sludge shrinks 90% by weight. Char’s just 10-20%. Landfills breathe easy. No leachate seeping toxins.

No open fires mean low smoke. Pathogens die at high heat. Over 500°C zaps bugs and chemicals. Safer ground.

One plant handles 10 tons daily. That’s 3,000 tons yearly gone from sites. Air stays clearer, soil healthier.

Get oil out. Up to 75% yield from sludge. Refines to fuel. Gases heat the next batch. Self-sustains.

Char sells as carbon filler. Tires, plastics? Mix in for roads. Full circle from waste.

Think oceans too. Less sludge dumped means cleaner waves. Fish thrive, beaches stay pretty.

These shifts build your green story. Clients nod, regs ease.

Payback’s quick. Setup costs upfront, but runs cheap.

Dumping runs $200 per ton. Pyrolysis? No truck hauls, no pit digs. Very low cost.

Energy from gases cuts fuel buys. One setup powers itself. Bills halve.

Scale up. Big ops hit ROI in 18 months. Small ones? Two years tops.

Oil sells at $400 per ton. From 10 tons sludge, pull 7 tons back. That’s $2,800 daily.

Char fetches $100 ton. Gases? Free heat or sell as fuel.

Table shows rough math for a mid-size plant:

| Input (Tons/Day) | Oil Yield (Tons) | Char (Tons) | Daily Revenue Estimate |

| 5 | 3.5 | 1 | $1,500 |

| 10 | 7 | 2 | $3,000 |

| 20 | 14 | 4 | $6,000 |

Numbers stack. Your bottom line grows.

Not a one-off. Blends with what you do.

Pyro oil’s raw. Distill it next. Separate lights from heavies. Get diesel, gasoline cuts.

Full chain: Sludge in, fuels out. One site handles all. Less shipping, more control.

Mix with tire pyrolysis. Shared heat saves 30% energy.

In Asia, a refiner cut sludge piles 95%. Oil back to tanks. Zero fines.

Europe plant turns drill waste to road char. Locals cheer clean sites.

Your turn. Start small batch. Scale as wins roll in.

Hands-on tweaks matter. Train crews on feeds. Monitor yields. Adjust for sludge type.

Every fix has snags. Pyrolysis too.

High temps need thick steel. Cracks? Big risks. Pick tough builds, check welds.

Fumes? Scrubbers catch them. Meet air rules easy.

Wet sludge gums up. Dry first. Fans or presses work.

Small runs test waters. Big jumps need space, power.

Partner with pros. They handle permits, tweaks.

Costs front-load. Grants for green tech help. Payback covers it.

Face facts. It’s not magic. But smart setup dodges most pits.

Right tools show you’re ahead. Pyrolysis marks you as forward-thinker.

Teams run smoother. Less waste chase, more core work.

Brand shines. “We recycle our mess” draws talent, partners.

Share wins. Site tours, reports. Builds trust, pulls business.

In oil’s rough world, this edge counts. You lead, others follow.

When eyeing oil sludge pyrolysis gear, Qingdao Xingfu Energy Equipment Co., Ltd steps up strong. Started in 2010 in Shandong, this outfit dives deep into waste handling systems. Their crew packs 78 techs and 136 skilled hands across a 70,000 square meter site. They craft from boilers to full pyrolysis lines, all CE and ISO stamped. Exports hit 30 countries, from Asia to Europe. Focus on tough, efficient builds keeps sites humming. After-sales? Quick parts, training. Solid pick for turning sludge to gains.

All in, exploring the advantages of oil sludge pyrolysis reveals a smart path. It slashes waste, grabs resources, and pads pockets. Environment thanks you, regs back off, outputs pay bills. Tie it to your flow, and ops level up. Whether small site or big field, this heat-based fix delivers. Dive in, tweak as you go, and watch the shifts.

Oil fields pile up sludge fast. Pyrolysis cuts that pile 90%, pulls back fuel oil, and skips dump fees. Cleaner sites, steady cash flow.

It zaps toxins, shrinks volume, and recycles into fuels. Less landfill, low emissions. Your op looks sharp to watchers and watchdogs.

Sure. Batch setups handle tons weekly. Low run costs, quick yields. Start modest, grow as returns hit.

Raw pyro oil refines easy with distillation. Get clean diesel from the mix. Boosts value, fits your fuel needs tight.

High heat, but sealed runs keep it tame. Scrubbers clean air, sensors watch temps. Train up, and risks drop low.