Materials from pyrolysis are transforming sustainable building by turning waste into high-performance additions. This piece looks at how biochar, pyrolysis oil, and syngas boost material qualities while fitting circular economy ideas.

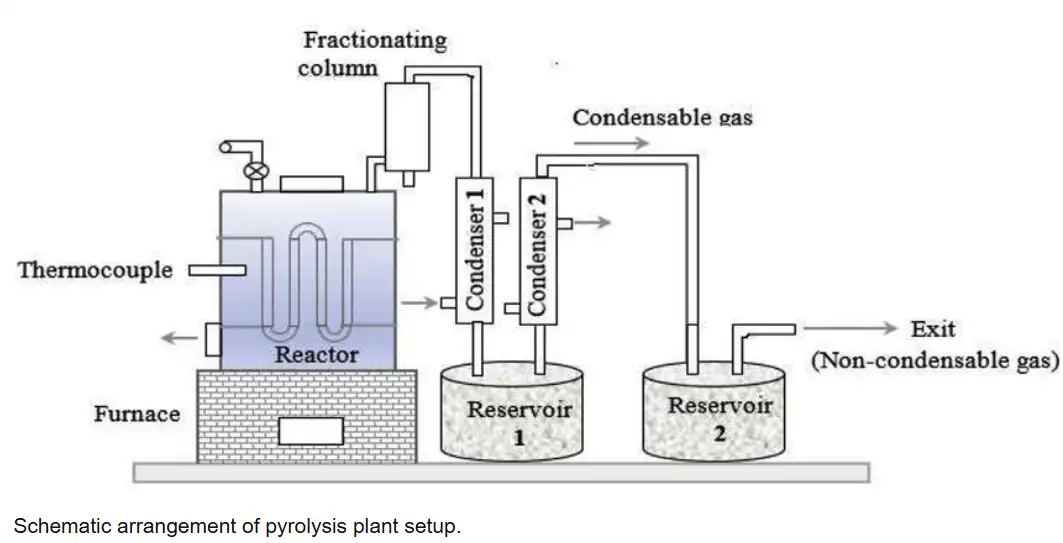

Pyrolysis changes old tires, plastics, and plant matter into useful resources through heat breakdown without air. The method creates three main outputs—fuel oil, solid rich in carbon, and syngas. Each has specific uses in building.

Pyrolysis is a heat-driven breakdown process. It happens without oxygen. It breaks down organic stuff at high heat. This process makes three main things: pyrolysis oil, syngas, and solid leftovers rich in carbon, like biochar or carbon black. What comes out depends on the starting material and how the pyrolysis setup works.

The amount recovered from old tire pyrolysis includes: Fuel oil: 40-45%, Carbon black: 32-36%, Steel wire: 14-16%, Syn gas: 5-8%. Plastic pyrolysis setups can make: Fuel oil: 60-85%, Carbon black: 10-30%, and Syn gas: 5-10%.

From concrete improved with biochar to asphalt changed with tire-based modifiers, pyrolytic outputs provide flexible answers. Their special traits, like high porosity and heat stability, fix important problems in old material performance.

Biochar is a solid rich in carbon. It is made during pyrolysis, especially from plant sources. It has high porosity and surface area. This makes it good for adding to building stuff like concrete. It improves mechanical and heat qualities.

Also called bio-oil or oil from tires, this liquid fuel can be used in changed asphalt binders. The fuel oil can power diesel engines, heating systems, and industrial furnaces.

Syngas is a burnable gas mix. It can work as a helper power source in material making. It can also be used in closed systems for energy recovery in building factories.

Xingfu Energy’s fully automatic pyrolysis plants make all three main outputs well. They do this through multi-stage cooling and sealed high-heat feeding.

Additives from pyrolysis boost strength against force, fire resistance, and environmental toughness. Biochar’s filler effect lifts concrete compression strength. Meanwhile, carbon black strengthens plastic mixes for tough building jobs.

Materials from pyrolysis, like biochar and carbon black, show big promise. They improve how building composites perform mechanically.

Biochar’s fine particle form makes bonding better in cement mixes. Studies show adding biochar raises compression strength. This is due to its filler effect and inner curing ability. Likewise, carbon black from pyrolyzed tires improves bend strength in plastic mixes. It does this by strengthening the material structure.

Adding pyrolytic products like biochar to building materials gives big heat insulation and fire resistance pluses.

Biochar has low heat conduction. This makes it a great insulating addition. When put into wall boards or insulation sheets, it cuts heat movement a lot. It also boosts fire resistance because of its high carbon content.

Carbon-rich materials from pyrolysis help building products last longer. They do this by improving water control and UV resistance.

Carbon-rich leftovers like biochar better control water holding in concrete. They also improve UV resistance in outside plastic uses. This helps them last longer in harsh conditions.

Xingfu Energy’s final products like carbon black are made using granulation. This ensures even particle size, good look, no dust escape, and high environmental protection.

Concrete, asphalt, and plastic mixes see the biggest gains. Biochar cuts seep-through in cement mixes. Pyrolysis oil changes asphalt binders. These offer cheap and eco-friendly choices instead of new materials.

Concrete mixed with biochar shows better strength-to-weight balance. It has less shrinkage cracking and improved freeze-thaw toughness. Also, biochar works as a tiny-pore filler. This lowers seep-through.

Pyrolytic oils from tires or plastics can replace some regular bitumen in asphalt. This not only boosts rutting resistance but also lowers the environmental harm linked to oil-based binders.

Carbon black from pyrolyzed rubber waste toughens plastic bases. These are used in building panels, pipes, and insulation sheets. It does this by improving pull strength and heat stability.

Xingfu Energy’s product list includes whole tire pyrolysis plants. These allow direct feeding without cutting. This lowers work costs. It also gives steady outputs like carbon black for composite strengthening.

By reusing waste flows and trapping carbon, pyrolysis helps low-impact building. Life cycle checks show drops in emissions and energy use. This fits global green building rules.

Swapping new raw materials with pyrolytic products cuts greenhouse gases. These are tied to cement making and oil pulling. Biochar traps air CO₂ when put into concrete for long times.

Pyrolysis turns end-of-life tires and plastics into valuable building inputs. It keeps them out of dumps or burning. It also pushes circular resource use.

Life cycle checks show big environmental gains when using bio-based or recycled pyrolytic stuff. This is compared to old choices—especially for energy use, emission cuts, and resource saving.

Xingfu Energy’s gear allows constant closed-loop making. There is no dust escape through sealed systems. This backs sustainable making that fits green building rules.

Changes in starting material and rule blocks slow adoption. Yet, advanced setups like Xingfu Energy’s automatic plants promise steady quality. This bridges gaps in standards and fit.

Adding pyrolytic stuff needs careful mixing. This avoids bad effects on workability or setting time in cement systems. Similarly, mixing pyrolytic oils into asphalt needs exact heat control. This keeps performance steady.

Differences in starting stuff—especially city waste plastics—can cause swings in product quality. This includes oil thickness or char particle size spread. Setting standards is still hard for big use.

Even with rising interest, national rules often lack ways for using other stuff like biochar or recycled oils in structural jobs. Approval paths need more work to help market entry.

Xingfu Energy tackles these limits through quality-focused design. They use x-ray checked welding for plant safety. They also offer modular setups made for different starting stuff.

New studies fine-tune biochar amounts and look at nano-structured carbon for smart stuff. New ideas in pyrolysis tech, like high-efficiency oil recovery, widen its building potential.

New studies find the best biochar amounts. They balance mechanical performance with workability. Others check how heat from syngas can cut embodied energy during material curing.

New research looks at nano-structured carbon blacks from tire sources. These boost electrical flow or EMI shielding traits. This spreads their use past structure into smart building parts.

With fully automatic plastic pyrolysis plants getting up to 85% fuel oil recovery, Xingfu Energy backs new ideas. They give reliable raw material flows for research-led progress.

A leader in pyrolysis plant making, Xingfu Energy mixes certified quality with green design. Their closed-loop setups and granulated carbon black outputs set industry marks for trust and environmental care.

QINGDAO XINGFU ENERGY EQUIPMENT CO., LTD makes pyrolysis plants and oil cleaning gear. Their standing comes from certified quality systems. These include AAA credit ratings known across China’s energy field.

Their offers include waste tire pyrolysis plants (whole/broken), plastic pyrolysis units (full/semi-auto), oil cleaning plants, carbon black granulation lines. All are made for good recovery of building-useful outputs like fuel oil, steel wire, carbon black.

The firm uses underwater arc welding with x-ray checking. This lifts plant safety levels. They also use pulse dust removal during unloading. This shows their drive for clean making ways that fit global green goals.

Pyrolytic products offer many pluses across better strength, heat insulation, toughness boost, emission cuts, and circularity push. But they need careful adding plans backed by standard methods. Suppliers like Xingfu Energy give solid tech bases needed to grow these new ideas across the building field.

Biochar lifts compression strength. It lessens shrinkage cracks and boosts freeze-thaw resistance. This happens because its hole-filled form acts as tiny fillers inside cement mixes.

Yes. It can partly replace bitumen if mixed right under controlled heat. This makes it more bendy while lowering need for oil-based binders.

When got from certified steps like Xingfu Energy’s—with sealed setups stopping emissions—the environmental dangers are small. This is compared to old trash ways like dumping or burning.