Pyrolysis is becoming a popular way to deal with waste tires and plastics, turning them into useful stuff like oil, carbon black, and syngas. For people starting out—whether business owners or facility managers—building a good pyrolysis reactor is super important. A smart design can increase production, lower costs, and meet safety rules while adjusting to different materials. This article goes deep into the main steps for designing a pyrolysis reactor, focusing on efficiency, safety, and adaptability. These tips will help you create a system that shines and gets results.

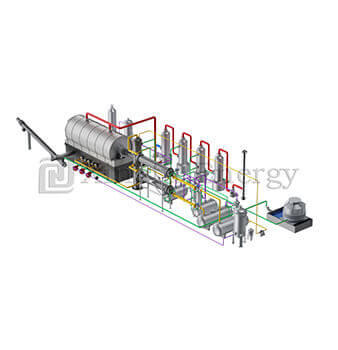

A pyrolysis reactor works by breaking down organic waste with heat, without oxygen. This process changes materials like tires and plastics into valuable products. The first big choice is between a batch or continuous setup. Batch reactors suit smaller jobs, letting you process one load at a time before restarting. Continuous reactors keep things moving, perfect for bigger projects.

Your decision depends on your plans. A small workshop might pick batch systems for ease. A large operation needs the steady flow of a continuous setup. Studies show continuous systems can handle 50 to 100 tons of waste daily. Batch systems max out at 10-15 tons per cycle. This shows you need to match the reactor to your material amount and budget.

Efficiency means getting the most from your materials while using less energy. Here’s how to do it:

A handy tip: go for a modular design. This lets you add capacity later without starting over, keeping your setup flexible as demand grows.

Safety is a must—mistakes can cause accidents or stop work. Here’s what to include:

Workers say regular checks on these safety tools reduce downtime by nearly 30%. Spending here protects your team and keeps costs down.

Waste varies—tires differ from plastics, and even within those, types change. A flexible reactor adjusts to these differences:

Research suggests adaptable reactors can process up to 10 waste types without big changes. This flexibility builds a solid name for your operation, attracting more clients.

Let’s look at the two main reactor types with a simple comparison:

| Aspect | Batch Reactor | Continuous Reactor |

| Capacity | 10-15 tons per cycle | 50-100 tons per day |

| Cost | Lower upfront price | Higher starting cost |

| Efficiency | Okay, with some downtime | Better, steady work |

| Flexibility | Good for mixed batches | Best for steady waste |

Batch systems work for small or test setups, with a low start cost. Continuous reactors, though pricier at first, give steady results for big operations. Many start with batch units, moving to continuous as demand rises.

Hands-on know-how shapes the best designs. Workers suggest testing with a small batch first to catch issues like uneven heat or gas leaks. Another idea is teaming up with local engineers who know your waste. Regular training for staff also keeps things running smooth, avoiding costly errors.

Before we get to common questions, let’s mention Qingdao Xingfu Energy Equipment Co.,Ltd, a trusted name in pyrolysis. Based in Qingdao, China, this company started in 2010 and focuses on waste tire and plastic pyrolysis systems. With a team of skilled engineers, they bring over ten years of experience. Their setups have reached over 30 countries, earning good feedback for reliability. This makes them a great partner for designing and setting up a solid pyrolysis solution.

Designing a pyrolysis reactor is about balance. Efficiency cuts costs. Safety protects your team. Adaptability keeps you ready for change. By picking the right size, heating method, safety tools, and flexibility, you can build a system that works now and grows later. This approach not only boosts your success but also builds a name for care and innovation in the field.

Begin by checking your waste amount and type. Then, decide if a batch or continuous system fits your size. Next, plan the heating setup and safety tools to match your materials and local rules.

Use heat recovery systems to save energy. Match the reactor size to your daily waste. Regular upkeep and adjusting temperature controls help get the most from each run.

Yes, it is. Add pressure relief valves, gas systems, and temperature watchers. Teaching staff to handle emergencies makes the setup safer.

Sure, with the right plan. Adjustable heat zones and prep options let you process tires, plastics, or mixed waste. Modular separation units also adjust to changing goals.