Pyrolysis of plastic to fuel is a heat-based process. It happens without oxygen. You heat materials like plastic waste to high temperatures, from 350°C to 700°C. This breaks down long plastic chains into smaller pieces. The result is three main products: pyrolysis oil, carbon black, and syngas. The pyrolysis of plastic reduces environmental problems. It also fits with recycling ideas by turning waste into useful stuff. This process is popular because it handles plastic waste and makes sustainable energy.

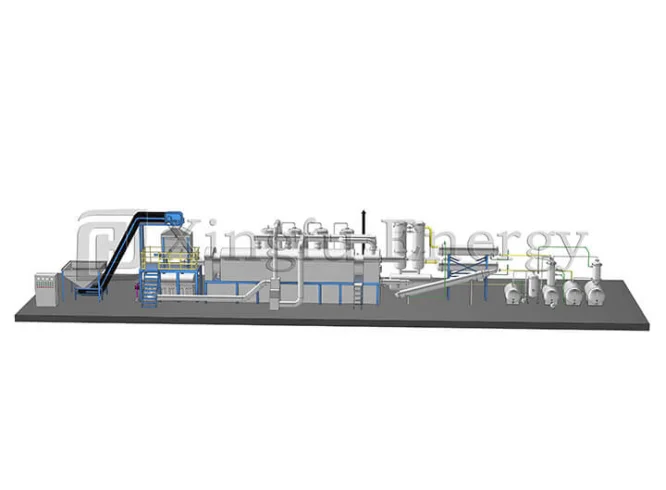

A pyrolysis plant has several important parts. These help turn plastic waste into fuel well:

Feeding System: This part puts plastic waste into the pyrolysis reactor. Advanced systems, like those in Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic plastic pyrolysis plant, make this step smooth.

Pyrolysis Reactor: The main part where heat breaks down the plastic under controlled conditions.

Cooling System: Multi-level cooling turns hot vapors into liquid fuel oil.

Gas Purification Unit: This cleans syngas so it can be reused to power the plant.

Discharge System: It removes leftovers like carbon black without harming the environment.

Qingdao Xingfu Energy Equipment Co., Ltd.’s semi-automatic plastic pyrolysis plant is very efficient. It has airtight high-temperature feeding and special heat reuse designs.

Starting a pyrolysis plant needs a big upfront cost. You pay for equipment, setup, and building the plant. Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic systems need less worker help. This can save money over time, even if the start-up cost is high.

Governments often give tax breaks or funds to support green tech like pyrolysis plants. Many places offer tax credits for waste-to-energy projects. These can make the starting costs much lower for investors.

Running a pyrolysis plant costs money for energy, workers, upkeep, and plastic waste. But syngas made during the pyrolysis of plastic can power the plant. This cuts down on energy bills a lot.

Upkeep costs are usually okay with strong equipment. Qingdao Xingfu Energy Equipment Co., Ltd.’s plants use advanced welding and x-ray checks. These make the equipment safe and last longer.

Making money is a big plus of pyrolysis plants. You can earn from:

Pyrolysis Oil: Used as industrial fuel or turned into diesel.

Carbon Black: Used to make rubber products and coatings.

Syngas: Sold or used to lower plant running costs.

Selling these products creates different income sources. Also, getting paid to take plastic waste from other businesses adds more money.

Plastic waste hurts the environment a lot. Old ways like dumping or burning plastic cause pollution and greenhouse gases. The pyrolysis of plastic offers a better way. It turns hard-to-recycle plastics into useful products.

Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic systems get up to 85% fuel oil. This shows they’re great at cutting down landfill use.

Switching to renewable energy is key to fighting climate change. The pyrolysis of plastic helps by making fuels like pyrolysis oil and syngas:

Pyrolysis Oil: Burns cleaner than regular fossil fuels.

Syngas: Used as a green energy source in industries.

This tech reduces the need for fossil fuels. It supports eco-friendly energy practices.

Pyrolysis plants help local areas by creating jobs. These include building, running, maintaining, and selling products. Other benefits are:

More Money: Selling products like carbon black brings in cash.

Helping Local Businesses: Buying plastic waste from nearby suppliers boosts the local economy.

Qingdao Xingfu Energy Equipment Co., Ltd.’s custom services make sure plants fit community needs well.

Running a pyrolysis plant means following strict rules. Governments set laws to make sure waste-to-energy plants are safe for the environment. You need permits for emissions, waste handling, and energy use. Not following these can lead to big fines or shutdowns.

Qingdao Xingfu Energy Equipment Co., Ltd.’s gas purification units clean syngas to reduce harm. Their semi-automatic plastic pyrolysis plants also have safe discharge systems. These keep byproducts like carbon black from polluting.

The pyrolysis process has some tough technical issues. Keeping the pyrolysis reactor at the right temperature (350°C to 700°C) is key. If the temperature is off, plastics might not break down fully. This can make lower-quality products.

Different plastics act differently when heated. This can make the process less efficient. Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic plastic pyrolysis plant has smart feeding systems. These handle mixed plastics well.

Cooling is another challenge. Multi-level cooling systems are needed to turn vapors into fuel oil properly. Without good cooling, you get less oil.

The demand for fuel from the pyrolysis of plastic depends on things like oil prices, green policies, and people wanting sustainable energy. As fossil fuel prices rise, pyrolysis oil is more wanted. But if oil prices drop, it can be harder to sell pyrolysis oil profitably.

Carbon black is used in many industries but competes with other sources. Qingdao Xingfu Energy Equipment Co., Ltd.’s carbon black granulation systems make high-quality products. This helps them sell at better prices.

Before investing, check if you can get enough plastic waste. A steady supply is key for the pyrolysis process to work well. City waste often has lots of non-recyclable plastics perfect for pyrolysis.

Partnering with local governments or businesses can secure long-term waste supplies. Some companies get paid to take plastic waste. This adds extra money.

Knowing market trends is important for a pyrolysis plant. The world is moving toward renewable energy. This boosts demand for pyrolysis oil and syngas. Starting early can make your business a leader and get long-term buyers.

People and laws are pushing for green practices. This creates chances to sell carbon black for things like rubber or coatings. But watch out for competition from other green energy tech or changes in government rules.

To figure out return on investment (ROI), look at start-up and running costs versus income. Start-up costs include buying pyrolysis reactors and cooling systems, plus setup fees. Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic systems cost more upfront but save on worker costs.

Running costs cover energy, upkeep, and getting plastic waste. Using syngas to power the plant cuts energy bills. Income comes from selling pyrolysis oil, carbon black, and extra syngas. You can also get tax breaks or funds for green tech.

Risks include breaking rules, technical problems like mixed plastic quality or equipment issues, and changing prices for products.

Their plants have multi-level cooling and airtight feeding systems. These boost efficiency and lower risks.

Yes, Qingdao Xingfu Energy Equipment Co., Ltd.’s fully automatic plastic pyrolysis plant handles mixed plastics well without hurting product quality.

You can earn money by taking plastic waste from businesses or cities. This also cuts landfill use through green practices.

Contact Qingdao Xingfu Energy for custom solutions that fit your needs.