In today’s world, sustainability is crucial. The worldwide effort for sustainable power solutions is more urgent than ever. Among inventive approaches tackling both ecological contamination and power shortages, tyre pyrolysis emerges as a significant innovation. This method converts discarded tyres into useful substances. These include liquid fuel, carbon residue, steel reinforcement, and synthetic gas. Such outputs substantially support circular economic models and sustainable power systems. Recycling former waste materials achieves two goals. It lessens ecological damage while supplying alternative power sources aligned with global environmental targets.

Tyre pyrolysis requires warming discarded tyres without oxygen. This breaks them into core components. Properly managed, the method prevents dangerous releases. It offers an eco-friendly answer to expanding tyre waste issues. Simultaneously, it creates energy-dense commodities. This article examines how tyre pyrolysis aids sustainable power. We will review its ecological and financial advantages. Additionally, we will see how firms like Xingfu Energy pioneer this transformative sector.

Automotive sector expansion creates mounting scrap tyre volumes. Industry assessments suggest over 1.5 billion tyres become waste yearly. This presents serious ecological problems. Unsound handling approaches like dumping sites or open burning cause land pollution, atmospheric harm, and public health dangers. Tyre pyrolysis tackles this concern. It transforms scrap tyres into valuable commodities. This decreases reliance on landfills and environmental damage.

Conventional tyre handling techniques release harmful substances. Burning or stockpiling discharges poisonous contaminants into air and earth. These activities add to climate-changing emissions. They also endanger habitats and community welfare. Conversely, tyre pyrolysis provides a cleaner option. It reduces releases and reprocesses substances into functional goods. This matches circular economy fundamentals.

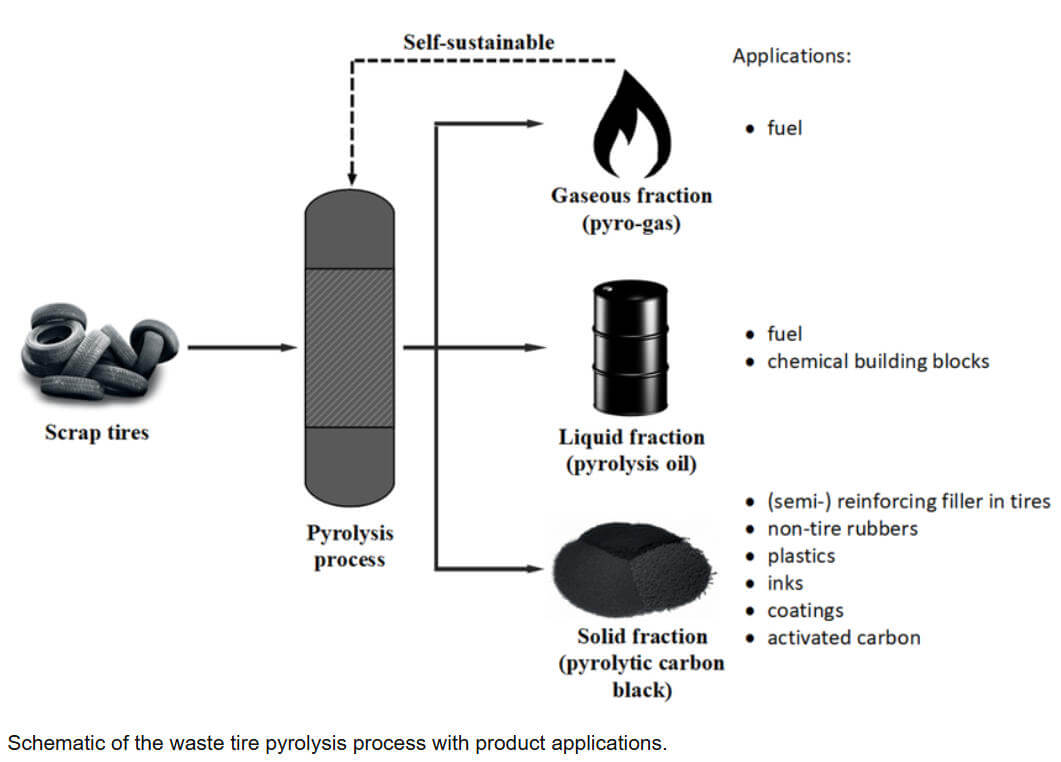

Tyre pyrolysis is a heat-driven chemical procedure. It involves warming scrap tyres at elevated heat levels. Temperatures typically range from 400–700°C. Crucially, this occurs without oxygen presence. This stops burning and permits tyre breakdown into several elements. Key results are:

-Liquid Fuel:A flexible power source for industrial heaters and kilns.

-Carbon Residue:A precious substance for making rubber goods, paints, and surface treatments.

-Steel Reinforcement:Reusable for manufacturing purposes.

-Synthetic Gas:A flammable vapor that powers the pyrolysis operation.

The system is notably productive. Modern setups attain fuel extraction rates near 90%. They ensure full material transformation. Contemporary facilities employ low-heat catalytic methods. These guarantee reduced power waste and peak productivity.

Breakthroughs in pyrolysis equipment have boosted effectiveness. Examples include sealed high-heat feeding mechanisms and tiered chilling layouts. These upgrades lower running expenses. They enhance fuel grade and assure adherence to strict ecological rules. For instance, recuperative heating layouts reduce power use. This makes tyre pyrolysis an economical and sustainable choice.

Liquid fuel from tyre pyrolysis serves as sustainable power. It can substitute conventional fossil fuels across industries. This oil possesses high energy content. It efficiently powers steam generators, concrete furnaces, and electricity stations. Replacing fossil fuels achieves two benefits. It reduces dependence on finite assets and cuts climate-changing releases.

Synthetic gas is a pyrolysis derivative. It is a blend of flammable vapors suitable for heat or electricity creation. In sophisticated pyrolysis facilities, this gas is reused to operate reactors. This forms a self-sufficient cycle boosting power efficacy. This self-sustaining trait establishes tyre pyrolysis as a major sustainable power contributor.

Carbon residue and steel reinforcement indirectly support sustainable power frameworks. Carbon residue assists sustainable production. It is utilized in new tyre fabrication and related products. This lowers demand for original substances. Similarly, reprocessed steel reinforcement serves manufacturing sectors. This further encourages material preservation.

| Product | Application | Contribution to Renewable Energy |

| Liquid Fuel | Industrial boilers, furnaces | Substitutes fossil fuels, lowers emissions |

| Synthetic Gas | Power generation, process heating | Enables self-sustaining energy frameworks |

| Carbon Residue | Rubber products, coatings | Decreases requirement for new materials |

| Steel Reinforcement | Manufacturing uses | Facilitates recycling and resource preservation |

Tyre pyrolysis solves ecological issues from scrap tyres. It turns them into beneficial commodities without hazardous releases. Improved systems feature sealed slag removal and cooling configurations. These guarantee a particulate-free and ecologically sound operation. This corresponds with global pollution control and sustainable waste handling goals.

Financially, tyre pyrolysis delivers major benefits. Generating liquid fuel and secondary goods builds new income avenues. Moreover, the process reduces disposal expenses for scrap tyres. Worldwide need for sustainable power and reprocessed materials is climbing. Consequently, pyrolysis facilities present profitable investment possibilities.

Tyre pyrolysis embodies circular economy concepts. It transforms refuse into assets. This diminishes rubbish, preserves resources, and produces sustainable commodities. These goods re-enter economic cycles. This comprehensive strategy secures both environmental and financial sustainability.

Established in 2010, Qingdao Xingfu Energy operates from Shandong, China. This technology-focused firm researches, develops, and produces scrap tyre/plastic pyrolysis systems. A dedicated research group includes 78 technical staff and 28 designers. Xingfu Energy has become a worldwide frontrunner in pyrolysis. The company occupies 70,500 square meters. This encompasses a 21,000-square-meter factory. It employs 228 personnel, including 65 certified metal joiners.

Xingfu Energy’s pyrolysis facilities are celebrated for cutting-edge technology. Their configurations incorporate unified designs for simple setup. Sealed high-heat feeding and layered chilling systems optimize fuel extraction. The organization exports to 30+ nations. These include Turkey, Mexico, Spain, Malaysia, and Finland. They have built a solid image for excellence and dependability. With CE and ISO9001 accreditations, Xingfu Energy pledges eco-conscious and economical solutions. These aid sustainable power and waste management.

Xingfu Energy has executed global pyrolysis schemes. These demonstrate the technology’s practical value. For example:

-Turkey:15-ton fully continuous scrap tyre facility with vapor treatment. This improved power efficacy and ecological standards.

-Mexico:20-ton semi-continuous tyre/plastic unit using electricity and synthetic gas. This displayed adaptability in power selections.

-Spain:15-ton fully continuous operation with upgraded reactor design. This maximized fuel recovery and functional effectiveness.

These initiatives underscore tyre pyrolysis’s global relevance. They show its role in solving regional waste handling and power requirements.

Tyre pyrolysis’s role in sustainable power is clear. It changes scrap tyres into vital assets. These include liquid fuel, synthetic gas, carbon residue, and steel reinforcement. This technology tackles critical ecological issues. Concurrently, it supplies sustainable power answers. Firms like Xingfu Energy lead this transformation. They provide sophisticated pyrolysis systems merging efficiency, ecological accountability, and financial feasibility. The planet persistently seeks novel methods to fight waste and decrease fossil fuel dependence. Here, tyre pyrolysis shines as a promising solution. It propels movement toward a purer, more sustainable tomorrow.

Tyre pyrolysis thermally decomposes scrap tyres without oxygen. It yields liquid fuel, synthetic gas, carbon residue, and steel reinforcement. Its sustainable power role involves creating liquid fuel and synthetic gas. These replace fossil fuels and bolster sustainable power frameworks.

The process decreases ecological harm by reprocessing scrap tyres. Advanced setups ensure minimal particulate releases. This reduces landfill usage and stops soil/air pollution. Thus, it advances sustainable refuse handling.

Results include liquid fuel (industrial uses), synthetic gas (power creation), carbon residue (rubber commodities), and steel reinforcement (reprocessing). These outputs aid both sustainable power and material conservation.

Xingfu Energy provides progressive, effective, and eco-friendly pyrolysis plants. Features include sealed feeding and layered chilling systems. With 10+ years’ experience and global projects, they are an industry-trusted pioneer.

It converts scrap tyres into reusable commodities. This reduces rubbish, saves materials, and creates sustainable industrial inputs. The method embodies circular economy fundamentals, aiding environmental and financial sustainability.