The pyrolysis of oil sludge faces several technical hurdles. These include changeable raw material makeup, large water amounts, and problems reaching the best thermal breakdown. Overcoming these difficulties is crucial. It helps get the most product and keeps the process steady.

Oil sludge varies a lot in its parts. This depends on its source—like petroleum refining, drilling, or storage tank cleaning. This difference makes pyrolysis hard. Different raw materials might need different heat levels for the best breakdown. Changes in oil content, ash amounts, and dirt can cause uneven reactions. This leads to unstable product amounts.

A frequent problem is the high water found in oil sludge. This lowers heat efficiency and raises energy use. The water must evaporate before good pyrolysis can happen. This demands extra preparation steps like drying or water removal.

Pyrolysis needs exact heat control. This ensures complete thermal splitting of hydrocarbons. It avoids creating unwanted side materials. Not enough heat can cause incomplete breakdown. However, too much heat might harm equipment or cause more coking.

Effective heat movement is key for even temperature spread inside the reactor. Yet, the thick and sticky character of oil sludge blocks good heat penetration. Therefore, reactor designs must include better heat exchange systems. This keeps the heat profile steady.

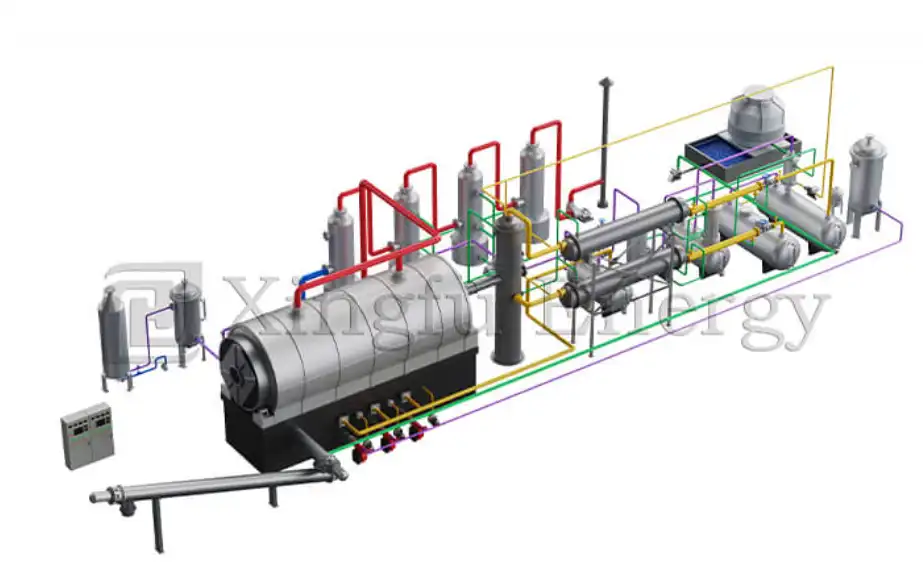

Xingfu Energy addresses these technical issues. They offer fully continuous systems. These systems feature airtight high-temperature feeding and multi-level cooling design. This improves heat recovery and guarantees steady output quality.

The efficiency and reliability of oil sludge pyrolysis depend a lot on reactor design. Heat movement methods and heat control are also vital. Picking the right system—batch or continuous—can greatly change operational success and long-term survival.

The reactor type—batch, semi-continuous, or fully continuous—matters greatly for operational steadiness. Fully continuous reactors work better for big operations. They handle steady-state conditions easily. They have very little downtime.

Batch systems are simpler. But they are less effective. This is because of frequent loading and unloading cycles. On the other hand, fully continuous systems offer better scaling and automation. However, they need more complex control systems. They also need higher starting investment.

Oil sludge’s sticky character often causes material buildup inside reactors. This buildup leads to coking. Coking weakens heat movement and shortens equipment life. Regular upkeep and anti-coking coverings are essential for long-term reliability.

Exact heat regulation is critical. It maximizes oil recovery while reducing emissions. Modern systems use automated PLC controls. This ensures stable operation even with varying raw materials.

Xingfu Energy’s pyrolysis plants use hot air heating. They combine this with unique heat recycling designs. This cuts operating costs. It also ensures the best thermal performance.

Pyrolysis creates harmful emissions like VOCs, SOx, and tiny particles. Following environmental rules is critical. Putting in advanced gas treatment systems ensures sustainable operations. It also avoids legal fines.

Pyrolysis makes several emissions. These include volatile organic compounds (VOCs), sulfur oxides (SOx), nitrogen oxides (NOx), and tiny particles. These emissions are environmental dangers if not handled properly.

Strict worldwide rules require effective gas treatment answers. The market for oil sludge pyrolysis equipment is heavily influenced by regulations governing the disposal of oil sludge. Not following rules can lead to fines or shutdowns.

Old scrubbers or filters might not catch all harmful substances well. This is especially true at high processing rates. Advanced treatment systems are often needed. These include catalytic converters or plasma reactors. They are needed for rule compliance.

Xingfu Energy adds pulse dust removal during discharge processes. This ensures no dust emissions. It supports cleaner operations that meet rule expectations.

Keeping pyrolysis systems running needs strong automation. Regular upkeep and skilled workers are also key. Ensuring steady performance demands attention to high-temperature part life and watching the process.

High operating temperatures speed up wear on reactor linings, seals, and heating parts. Preventive upkeep schedules are necessary. They avoid unplanned stoppages.

Automated systems need reliable sensors and control programs. They must work well under changing conditions. Faulty sensors can cause process instability or safety risks.

Because oil sludge processing is dangerous, skilled workers are vital. Proper training makes sure safety rules are followed during normal work and emergencies.

Xingfu Energy improves system dependability. They use features like airtight high-temperature deslagging mechanisms. These reduce manual work. They also keep operations clean.

High starting costs and shifting market desire for byproducts create money problems. However, smart investments in efficient technologies can boost return on investment. This is done by improving resource recovery and lowering running costs.

One major obstacle is the upfront cost for advanced pyrolysis equipment. The initial investment in oil sludge pyrolysis equipment can be substantial, posing a financial challenge for some organizations.

Running costs include energy use, labor, and upkeep. Long-term returns come from recovered resources like fuel oil and carbon black. The balance between these factors decides money feasibility.

Money success also depends on market desire for byproducts. These include pyrolysis oil or carbon black granules. Changing goods prices can affect profits.

Xingfu Energy improves return on investment. They do this through integrated solutions like carbon black granulation systems. These are made for closed-loop production. They have zero dust leakage.

Energy efficiency is key to cutting running costs in pyrolysis. Adding heat recovery systems helps. Better insulation and adding extra heating methods also help. These steps can greatly improve thermal performance.

Catching leftover heat from exhaust gases or reactor walls can cut fuel use a lot. This heat can be sent back into pre-heating zones or drying units.

Extra heating uses waste heat boilers or renewable sources like solar panels. This boosts overall system efficiency. It does this without raising emissions.

High-quality insulation materials help keep internal temperatures better. This reduces energy loss during long operation times.

Xingfu Energy uses unique submerged arc welding methods. They combine this with multilevel cooling circulation. This maximizes fuel oil recovery. It also lowers energy use.

Getting high-quality pyrolysis oil and valuable byproducts depends on exact process control. Good residue handling is also important. Advanced refining technologies further improve product market appeal and profits.

Raw material makeup, time in the reactor, heat pattern, and condensation effectiveness all change how much recoverable oil comes from each batch.

Byproducts like char must be managed properly. This avoids environmental harm. Finding business uses is also important. These uses include building materials or activated carbon creation.

After-treatment methods include distillation units. These can make fuel quality better. They remove impurities like sulfur or heavy metals from raw pyrolysis oil.

Xingfu Energy’s product recovery rate ranges between 40-45% fuel oil, 32-36% carbon black, 14-16% steel wire. This highlights their dedication to maximizing resource use.

Xingfu Energy is a top pyrolysis technology provider. They offer custom, high-efficiency systems with strong after-sales help. Their knowledge in continuous pyrolysis answers makes them a solid choice for industrial uses.

As a specialized maker, Xingfu Energy brings wide experience in pyrolysis system design. Their technical knowledge tackles the complex problems of oil sludge handling.

QINGDAO XINGFU ENERGY EQUIPMENT CO., LTD is a professional manufacturer specializing in pyrolysis plant and oil distillation equipment. Their portfolio includes setups across different areas. These include waste tyre recycling and plastic pyrolysis systems.

Their offerings include whole tyre feed systems needing no cutting. They also have broken tyre units with airtight high-temperature feeding systems. These are made for fast setup.

From technical training to spare parts supply, Xingfu Energy ensures full help through the system’s life. This makes them a reliable partner. They are known worldwide for good engineering answers.

Solving problems in oil sludge pyrolysis needs a combined method. It mixes advanced technology with practical operational plans. From handling raw material differences to improving reactor design and emissions control systems—each part is vital. They ensure lasting performance. Companies like Xingfu Energy stand out. They deliver complete solutions backed by innovation-driven engineering. This tackles both technical obstacles and money limits well.

Most kinds can be treated by pyrolysis. These include refinery sludge, tank bottom sludge, drilling muds, and oily wastewater leftovers. It depends on water amount and makeup changes.

Yes. When fitted with proper emission controls, pyrolysis offers a money-saving option. It is better than old disposal ways like landfilling or burning. It also makes valuable byproducts like fuel oils and carbon black.

Setup time changes based on system complexity. However, integrated designs from Xingfu Energy skip foundation needs. This allows faster setup, usually within weeks. It depends on site readiness.