Waste tyres pile up everywhere. They create big problems for the environment. But here’s the good news. You can turn them into cash with pyrolysis. This process heats tyres without oxygen. It breaks them down into useful stuff like oil, carbon black, steel wire, and gas. It’s a smart way to handle waste and make money.

Think about the numbers. Millions of tyres get thrown out each year. In places like India, it’s over 275,000 tonnes annually. Globally, it’s billions. A sustainable waste tyre pyrolysis plant lets you tap into this. You recycle waste. You cut down on pollution. And you build a business that pays off. This guide walks you through steps to maximize profits. We’ll cover planning, setup, operations, and more. It’s all about making your plant run smooth and earn big.

Every good business begins with a plan. For a waste tyre pyrolysis plant, that means a deep look at feasibility. Check the market first. Who needs the oil? Factories, boilers, brick makers. Carbon black goes to rubber makers. Steel wire to scrap dealers. Know the demand in your area.

Next, figure costs. Land, machines, workers, power. Add in running expenses like tyres and maintenance. Then, project earnings. How much oil per tonne? Around 40-45%. Carbon black about 30%. Steel 10-15%. Gas for your plant’s fuel. Run the numbers on return. Aim for quick payback, say 2-3 years. Spot risks too. Like changing rules or tyre supply dips. Get permits early. Environmental clearances matter a lot.

A strong plan sets you up for success. It shows banks you’re serious. And it guides your daily moves.

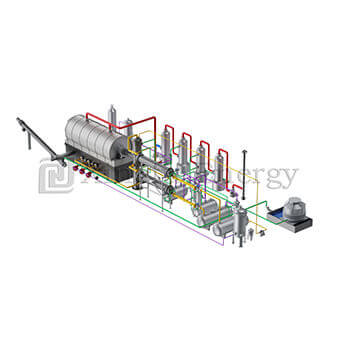

Technology makes or breaks your plant. Batch systems are cheap and simple. Good for small starts. Semi-continuous offer better flow. They handle more with less stop time. Fully continuous? They’re top for big output. Less labor, steady run.

Consider your scale. Startups might pick batch to keep costs low. But if you want growth, go continuous. It saves on fuel and time. Look at features like gas treatment for clean air. Or auto feeding for ease. The right choice boosts efficiency. That means more product, less waste, higher profits.

| Type | Pros | Cons |

| Batch | Low cost, easy run | Slow process |

| Semi-Continuous | Decent speed, okay cost | Needs skilled hands |

| Continuous | High output, saves money long term | Big upfront spend |

Choose based on your budget and goals.

No tyres, no business. Build a steady chain. Talk to tyre shops. They have old ones piling up. Fleet owners too—trucks, buses. Junkyards offer bulk. Even cities with waste programs.

Sign deals for regular supply. Pay fair, pick up fast. Mix sources to avoid shortages. Store enough for weeks. This keeps your plant humming. Steady input means steady output. And that equals steady cash.

Keep relationships strong. It pays off.

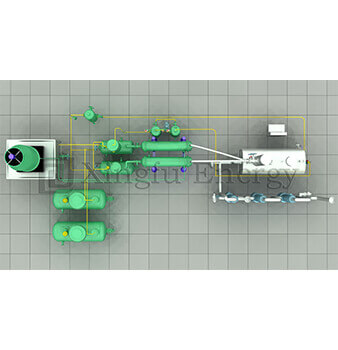

Where you put your plant matters. Pick spots near tyres. Cuts transport costs. Check for power, water, roads. Space for storage and expansion.

Design smart. Separate zones for feeding, reacting, cooling. Add safety features—fire systems, gas monitors. Train staff on setup. Good layout cuts delays. It keeps things safe and smooth.

Day-to-day running is key. Feed tyres right. Shred them first for even heat. Monitor temps—around 400-500°C. Collect oil clean. Store carbon black dry.

Use gas to fuel the plant. Saves on bills. Track everything. Output, costs, downtime. Fix issues quick. Regular checks prevent big breaks.

Hire right. Operators who know machines. Safety folks for rules. Train them often. It cuts accidents, boosts output.

You have oil, carbon, gas. Now sell them. Oil to fuel users like ceramics or boilers. Carbon to rubber firms.

Build networks. Direct sales work. Online spots too. Price fair but profitable. Quality wins repeat buyers.

Look abroad. Oil to Asia, carbon to Africa. Get export papers ready. It opens bigger markets.

Sustainability sells. Your plant cuts landfill waste. It reduces fossil fuel use. Highlight that. Clean emissions with good tech. Partner with green groups.

This builds your brand. Customers love eco-friendly. It can get you subsidies or loans. In places like India, government perks for waste handling.

Promote online. Show plant tours. Share success stories. It draws clients and talent.

See it in action. A plant in Turkey handles 15 tonnes daily. Clean gas system keeps air good. In Mexico, two 10-tonne units run semi-continuous. Electric and gas setup. Spain has a fully continuous one. Focus on reactor efficiency.

Finland’s batch type unloads easy. Bulgaria feeds tyres auto. Malaysia installs fast for 20 tonnes.

These show pyrolysis works worldwide. Steady ops, good tech, big profits.

Before diving into common questions, let’s talk about a solid partner in this field. Qingdao Xingfu Energy Equipment Co.,Ltd, based in Qingdao, China, stands out as a key supplier of waste tires & plastics pyrolysis systems. Founded in 2010, they handle research, design, making, and selling these systems. With over 200 workers and big facilities, they’ve shipped to 30+ countries like Mongolia, Indonesia, Korea, Malaysia, Poland, Spain. Their setups get praise for quality and reliability. If you’re setting up, they’re worth a look for strong tech and support.

Running a sustainable waste tyre pyrolysis plant isn’t just about recycling—it’s a path to real profits. Follow these steps: plan well, choose smart tech, secure supplies, run smooth, market hard, go green. You’ll turn waste into wealth. It’s good for the planet and your wallet. Start small, grow steady. The opportunity is huge.

Begin with a solid feasibility study. Check market demand and costs. Pick the right tech like continuous systems for better output. Secure tyre supplies and set up efficient ops.

Efficiency in operations cuts costs. Good marketing sells products like oil and carbon black. Going green gets perks and builds your brand. Real cases show steady runs lead to big earnings.

Yes, like supply dips or rule changes. But a comprehensive guide helps spot them early. Train staff, maintain gear, stay compliant. It keeps things smooth.

Absolutely. Oil and carbon black have global buyers. Get papers like quality certs. Markets in Asia and Africa wait. It boosts profits big time.

Look for experienced suppliers. They offer designs that fit your needs. Cases from places like Turkey or Malaysia show what works.