Pyrolysis plants are naturally dangerous. This is because of hot running, harmful releases, and risks of blast gases. Spotting these threats is the first move. It leads to putting strong safety rules in place. Below, we look at the main dangers. These dangers need strict reduction plans.

These plants run at very high heat levels. This heat often passes the point where gases ignite by themselves. Pyrolysis breaks down organic stuff at high heat without air. It links to serious safety worries. These heat dangers can cause burns, fires, or even harm to the plant structure. This happens if protection or holding steps break down.

The high heat often goes beyond the self-ignition heat of made gases. So, keeping air out is vital to stop blasts. Leaks of syngas or light fumes can happen during start, stop, or system faults. These leaks can mix with air to form blast mixtures. Using inert gas flushing (like nitrogen) is key. It pushes out air and stops blast situations.

Pyrolysis creates poisonous gases. Carbon monoxide is the most serious one. Contact with these gases can bring big health threats to workers and nearby people. Without proper release control setups like scrubbers or filters, these bad things can get into the air.

The pyrolysis method needs complex gear working under severe conditions. Gear breakdown can lead to very bad results. Too much pressure events, machine failures, or rust-caused breaks are common dangers. These happen without strict upkeep.

Qingdao Xingfu Energy has fixed these problems. They use sealed feed setups, several cooling designs, and special welding checked by X-rays in their plants. This makes heat steadiness and machine soundness better.

Fire and blast risks are among the most serious threats in pyrolysis work. Active steps are needed. These include inert gas systems, blast stopping setups, and emergency stop rules. They are vital for protecting people and the plant.

Keeping an air-free space is critical. Past accidents happened because air-free spaces failed. Inert gas setups using nitrogen are normal. They flush containers before start or stop. Blast stopping gear like flame blockers and pressure safety valves further lower risks.

Good airflow and gas watching setups are key. They find and handle harmful releases. Constant leak finding systems give early warnings. They alert if dangerous build-ups happen. Enough airflow stops light gases gathering inside closed spots.

Emergency stop tools let workers cut off faults fast. Firefighting gear is also vital. This includes sprinklers, foam systems, and water points. They must be placed carefully across work zones.

Qingdao Xingfu Energy uses several cooling flow setups. These lower heat focus and allow safer oil getting. This is a useful plan for cutting fire dangers in pyrolysis work.

Building answers play a main part in reducing pyrolysis plant dangers. These controls make safety better and work smoother. They range from best plant layouts to robot watching systems.

A well-planned plant separates high-danger spots. This lessens mixing threats. Control rooms, storage places, and reactors should be placed smartly. This cuts contact if things go wrong.

Hot reactors should be apart from control rooms and storage spots. This lessens contact if small events happen nearby.

Reactors must have burst disks or spring-loaded safety valves. Holding pools around tanks stop spill spread during leaks or overfills.

Robot control setups and safety links can watch and manage heat, pressure, and gas makeup in real time. SCADA systems allow distant watching. They also lower mistakes from human actions.

Qingdao Xingfu Energy uses full robot control in its waste tyre plants. These need only 2–3 workers per shift. This greatly lowers human contact and makes work smoother.

Preventive and predictive upkeep are key. They avoid surprise gear failures. Regular checks and advanced tests help keep the plant running well long-term.

Shake checks, heat pictures, and oil tests find wear signs before failure. This cuts unplanned stops and makes trust better.

Regular checks follow maker rules. They make sure pressure holders, pipes, valves, and burners stay within safe work limits.

Upkeep records help rule checks. They also give a trail for every fix done on key parts.

Qingdao Xingfu Energy sticks firmly to safety rules. They do this through written check routines. These match world rules like ISO marks built into their making steps.

Pyrolysis plants must lessen nature harm. They do this through modern pollution control and waste handling plans. Following rules and green ways are key to lowering nature risks.

Scrubbers, filters, and coolers catch bad releases before they go out. These setups follow nature rules and keep air clean.

Release control setups must be put in. Scrubbers or filters catch and stop bad gases before release. Coolers also split light organics from waste streams. This is done before safely letting them into the air.

Harmful leftovers need safe throw-away ways. This stops nature harm. Solid stuff like carbon black must be kept in sealed bins. Or it can be made into grains for reuse in factories.

Qingdao Xingfu Energy gives carbon black graining setups. These work in a sealed space with no dust escape. This meets both nature safety aims and stuff recovery speed.

Well-taught workers are the first shield against accidents. Full teaching plans make sure workers know safety rules and emergency steps.

Clear SOPs make sure work is the same across shifts. They include lock steps during upkeep or emergency stop moves during unusual events.

Regular drills make response faster during emergencies. Proof programs show worker skill. Ongoing teaching keeps staff up to date on new best ways.

Qingdao Xingfu Energy stresses worker teaching. This is part of its full project offers. It makes sure clients get both gear and work know-how aimed at top safety.

Sticking to trade rules and local laws is a must for pyrolysis plant runners. Following rules makes work legal. It also guards workers and the nature.

Proofs like ISO, CE, and ATEX show a promise to safety and quality. Hitting these marks is vital for world market entry.

Plants must follow release limits set by local nature bodies. These limits cover air bad things like CO₂ or VOCs.

Sticking to OSHA-like frames keeps workers safe. This is done through PPE needs, noise limits, and so on.

Outside checks prove plan soundness. Permits make sure work is legal. Regular checks confirm ongoing rule following as rules change.

Qingdao Xingfu Energy is known by many proof groups. This includes AAA rating bodies in China. It shows its promise through checked quality papers built into its making life. This helps world clients meet rule marks easily.

Qingdao Xingfu Energy is a top pyrolysis tech giver. It is known for its new, safety-following answers. Its world skill and promise to quality make it a safe partner for pyrolysis plant jobs.

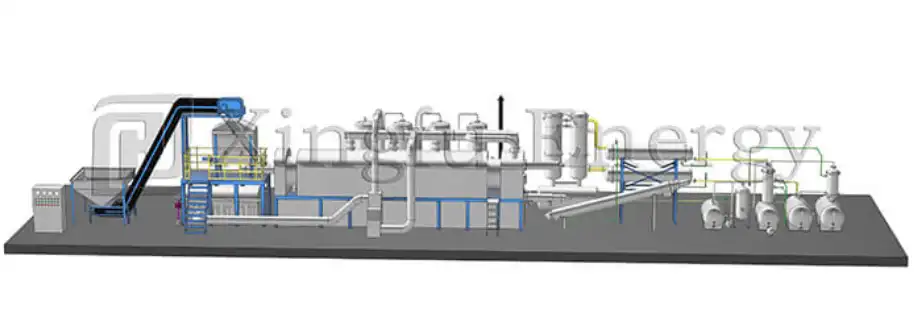

Qingdao Xingfu Energy Equipment Co., Ltd makes pyrolysis plant answers. These include waste tyre plants, plastic plants, oil cleaning units, and more. They have years of trade skill shown in their building power.

They use full robot special welding with X-ray checks. This makes plant safety levels much better. Their goods go through strict inside tests. These tests follow world rules before use everywhere.

Xingfu gives setup help worldwide. They also have after-sale teams that can do far-off checks. This is key because work time affects profit for clients running plants at scale.

Reducing risks in pyrolysis work needs many layers. Building controls like inert gas flushing help. Release handling via scrubbers is key. Robot-driven watching is important. Predictive upkeep matters. Strong teaching plans are needed. Rule checks are vital. Reliable tech givers like Qingdao Xingfu Energy support all this. They build these ideas into every plant they send. This covers from plan to start-up. It makes sure work is safe under extreme heat conditions.

Proofs might cover ISO 9001 (quality), ISO 14001 (nature), CE mark (for Europe), ATEX rule (for blast-proof zones), and others. These depend on local law needs.

Yearly outside checks are wise. Also do inside reviews each season. These should focus on high-risk parts like reactors or gas pipes. This keeps getting better always.

Yes. Robot control setups cut hand action mistakes. They give real-time notes on heat or pressure changes. They also allow faster fixes through locks or alarms.