Intelligent automation is changing pyrolysis, boosting efficiency through AI-powered control and constant monitoring. By improving thermal decomposition in oxygen-free settings, these technologies unlock greater yields and cleaner energy from varied raw materials. Leading innovators like Qingdao Xingfu Energy incorporate sophisticated automation to change waste into sustainable value.

Pyrolysis processes are essential for turning waste into energy and useful by-products. Essentially, these methods depend on thermal decomposition without oxygen. This unlocks chemical changes that intelligent technologies can control and improve.

The pyrolysis method involves intricate thermochemical reactions. These happen when organic substances are heated to high temperatures, typically between 300°C and 700°C, without oxygen. Consequently, long-chain hydrocarbons break into smaller molecules. This produces three main outputs: solid char (like biochar or carbon black), liquid oil (pyrolysis oil), and syngas.

Pyrolysis changes biomass, such as farm leftovers or wood pieces, into valuable items. These include bio-oil, biochar, and syngas. These reactions absorb a lot of heat. Therefore, precise control over temperature changes and reaction time is vital to maximize product yields.

The choice of raw material greatly affects pyrolysis system efficiency. Biomass, plastics, tyres, fabric waste, algae, and electronic waste each show distinct thermal behaviors. For example:

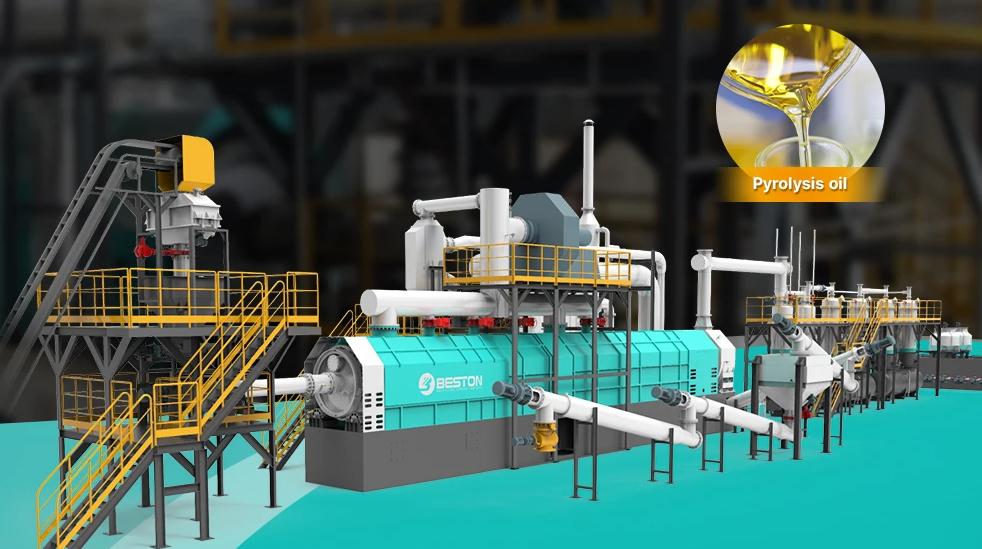

At Qingdao Xingfu Energy Equipment Co., Ltd., handling diverse materials is central to their system design. Their fully automatic plastic pyrolysis plant achieves a fuel oil recovery rate of 60–85%, carbon black 10–30%, and syngas 5–10%.

The main products from pyrolysis include fuel oil, carbon black or biochar, steel wire (from tyre processing), and syngas. Each holds commercial value:

The fuel oil can power diesel engines (high power, low speed), heating furnaces, and industrial furnaces. Carbon black powder is turned into uniform particles, sized 10-100 μm. This happens after humidification, mixing, granulation, and drying. Syngas is frequently reused within the system. This lowers the need for external fuel.

Xingfu Energy tackles these principles by providing custom solutions for different materials. They achieve optimized recovery rates across multiple product streams.

Growing demand for scalable waste-to-energy solutions makes automation crucial. It boosts throughput while maintaining exact process control.

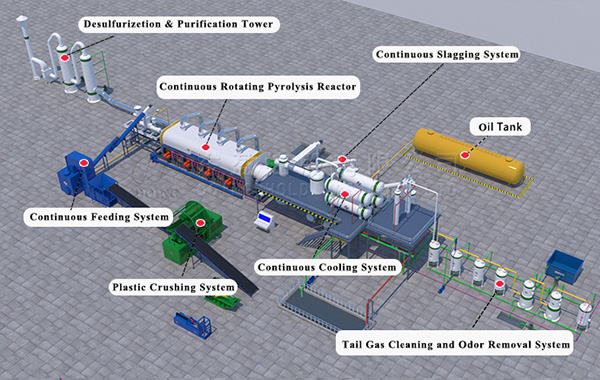

Sensors placed throughout pyrolysis systems give constant feedback. They monitor factors like temperature, pressure, gas makeup, and raw material flow rate. These inputs are crucial. They help spot problems early and guarantee steady quality.

IoT-Enabled Pyrolysis Systems: Internet of Things (IoT) technology allows for real-time monitoring and control of pyrolysis processes.

PLCs act as the core for automated operations. They run logic-based commands using sensor data. This dynamically adjusts burners, feed conveyors, cooling systems, or exhaust valves. It ensures the best reaction conditions without human help.

Collecting operational data over time via SCADA or DCS platforms lets operators study trends. This helps find inefficiencies or predict maintenance needs before breakdowns happen.

Xingfu Energy builds automation features into its plants. Examples are multilevel cooling circulation systems and airtight high-temperature feeding. These cut heat loss and improve fuel recovery. This shows how automation directly leads to performance gains.

AI technologies add a new layer to pyrolysis operations. They enable predictive insights and adaptable control strategies that evolve with operating conditions.

Machine learning models can study past operational data. They forecast outcomes like product yield or energy use under different conditions. These forecasts allow proactive adjustments. This reduces downtime or material loss.

AI and machine learning algorithms can analyze data from pyrolysis processes to predict outcomes and identify potential improvements.

AI models simulate various scenarios using digital twins. These are virtual copies of physical reactors. They test control strategies without affecting live operations. This helps refine setups for new materials or reactor designs.

Intelligent feedback loops automatically recalibrate settings. They do this based on real-time deviations from expected performance benchmarks. This makes the system self-correcting over time.

Xingfu Energy is well-placed to adopt AI-driven upgrades. Their modular system design supports sensor integration at all stages, from feeding to final product collection. This enables ongoing improvement cycles.

Intelligent control systems offer key advantages. These cover operational efficiency, cost reduction, safety improvement, and environmental compliance.

Constant monitoring combined with predictive algorithms ensures the best thermal profiles throughout the reactor. This maximizes conversion efficiency and minimizes unwanted by-products.

Automation-driven heat recycling designs, like those in Xingfu’s tyre plants, minimize energy use. They do this without reducing output:

Hot air heating, unique heat recycling design, to reduce the operating cost.

Intelligent controls lower human error risks. They automate critical safety functions, like pressure relief or emergency shutdowns. Dust-free deslagging systems further improve workplace safety:

Pulse dust removal during discharge process, no dust emissions.

Xingfu Energy meets strict environmental standards. It delivers consistent product quality through intelligent engineering in its fully automatic systems.

Different setups need tailored automation strategies. This depends on batch versus continuous operation modes or reaction speeds like fast versus slow pyrolysis.

Batch systems gain from scheduling optimization tools. These coordinate heating cycles effectively. Continuous systems need strong feedback loops for smooth operation. This is a strength in Xingfu’s whole tyre pyrolysis plant, which allows whole tyre feed, no need to cut; reduced the cost.

Fast pyrolysis needs quick heating rates with exact timing controls. Slow pyrolysis focuses on longer reaction times needing stable thermal conditions. Each requires different sensor-calibration methods.

Automated coordination between reactors, distillation columns (for refining oil), or granulators (for carbon black) ensures maximum recovery without holdups:

The whole process goes in closed state…No dust leakage…Continuous production, electronic quantitative pack, instead of labor.

Xingfu Energy supports both responsive continuous lines and batch units. They integrate downstream modules like distillation towers or carbon black granulators. This ensures smooth end-to-end processing.

Despite its benefits, intelligent automation brings technical complexities. These must be addressed during setup.

High-temperature conditions challenge sensor durability. Mixed raw materials introduce variability. This complicates algorithm training accuracy.

More connectivity brings more vulnerability. Securing PLCs against cyber threats is vital, especially with remote monitoring via IoT platforms.

Initial spending for automation infrastructure can be significant. However, long-term savings from lower labor costs and better yields often justify the investment over time.

Xingfu Energy uses airtight feeding designs to cut temperature loss. Multilevel cooling boosts oil recovery. This delivers return on investment through efficient engineering, not just digital extras.

Next-generation advances point to self-governing reactors. These can self-regulate based on real-time analytics supported by big data systems.

Autonomous plants aim to remove manual involvement entirely. They use AI-managed workflows, from start-up to shutdown. This vision matches Xingfu’s fully automatic plant offerings in plastic and tyre sectors.

Data lakes built from years of operational history enable large-scale insights. These cover seasonal material variations or equipment wear patterns. They feed back into smarter planning cycles across global fleets or facilities.

Modular mobile units powered by AI could bring local energy generation to remote areas:

These mobile units can be deployed…to convert waste into energy on-site…

Xingfu Energy’s modular design approach fits this trend towards decentralized smart energy hubs powered by intelligent automation.

Qingdao Xingfu Energy Equipment Co., Ltd is a top global manufacturer. They specialize in advanced pyrolytic systems designed around intelligence-driven performance.

With broad experience producing waste tyre pyrolysis plant, plastic pyrolysis plant, oil distillation equipment, Xingfu offers complete solutions. This is backed by decades of expertise in thermal processing.

Their portfolio includes fully automatic lines. These have features like multilevel cooling circulation systems and airtight high-temperature feeding. They also use submerged arc welding. All contribute to safer, more efficient large-scale operations.

From X-ray weld checks ensuring structural soundness to customizable granulation lines achieving zero-dust emissions, the spirit of being sincere, true…innovation, and excellence is what always pursues at Xingfu Energy—a trusted partner advancing intelligent pyrolytic solutions worldwide.

Intelligent automation is transforming waste conversion through pyrolysis. It improves operational precision with sensors and forecasts future outcomes using AI. Industry leaders like Qingdao Xingfu Energy keep integrating these technologies into scalable solutions. Their work spans tyres to plastics, unlocking cleaner energy paths rooted in circular economy principles.

Suitable materials include biomass (wood pieces/farm residue), plastics (household/industrial), tyres (whole/broken), fabric waste, algae biomass—and even electronic parts when processed via advanced reactors like plasma units.

Automation improves combustion efficiency, cutting emissions. Airtight feeding and dust-free discharge improve air quality compliance. Optimized heat recycling lessens fossil fuel dependence.

Yes. Older plants can be retrofitted with PLCs, sensors, and data modules for stepwise adoption. Manufacturers like Xingfu provide modular upgrades tailored to specific site needs.