Imagine you’re knee-deep in managing a waste recycling operation. Piles of old tires and plastics stack up, and your team scrambles to keep things moving without burning through cash on fuel or extra hands. Sound familiar? That’s where automation flips the script. In today’s waste processing world, fully continuous pyrolysis plants are changing the game, letting you handle massive volumes—like 30 tons a day—with just a couple of folks on shift. No more endless manual feeds or constant tweaks. This tech isn’t just efficient; it’s a smart fix for those nagging high costs and slow outputs that plague many setups.

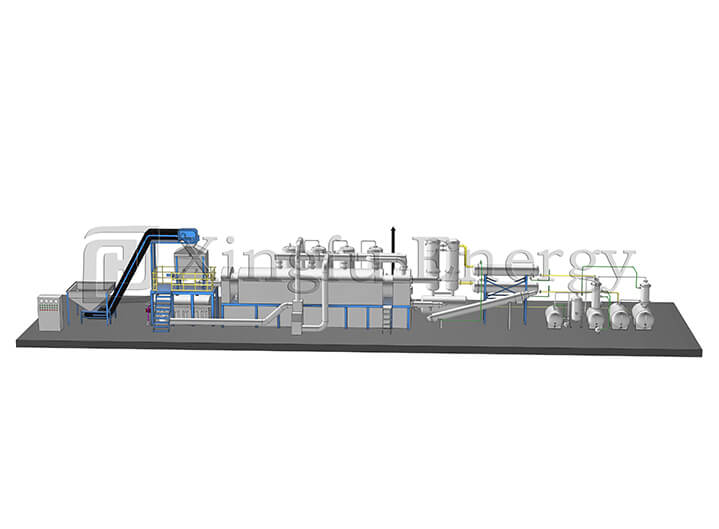

At its core, a fully continuous pyrolysis system breaks down waste tires and plastics into valuable stuff like fuel oil, carbon black, and steel wire, all while running non-stop. Unlike older batch methods that require stopping to load and unload, this approach keeps everything flowing. Think of it as a well-oiled conveyor belt in a factory—materials go in one end, products come out the other, with minimal human intervention. For businesses eyeing sustainable waste solutions, this means turning trash into treasure without the usual headaches.

Pyrolysis isn’t new, but the fully continuous twist makes it stand out. Basically, it heats waste in an oxygen-free environment to crack it into usable byproducts. The “fully continuous” part? That’s the magic. Materials feed in steadily, react, and exit as products without pauses. No batching up loads or cooling down reactors between runs.

Take a typical day in a waste yard. Trucks dump shredded tires—cut into pieces no bigger than 20mm. A conveyor whisks them straight into the reactor. Inside, hot air circulates at under 650°C, breaking everything down. Oil and gas separate in a tower, cool into fuel, and store away. Carbon black and steel wire? They auto-discharge, cool, and sort via magnets. Flammable gases get cleaned and piped back to heat the system. It’s seamless.

Why go fully continuous? Batch systems might handle smaller loads, but they demand more downtime—loading, heating, cooling, unloading. That adds up in labor and energy. Fully continuous setups slash those issues. Data from real installs shows they boost throughput by up to 50% over batch types, pulling in recovery rates like 45-50% fuel oil. And with environmental regs tightening, the enclosed design cuts leaks and dust, hitting European emission standards without extra scrubbers.

Diving into the 30T/D model, it’s built for scale. This beast processes 30 tons daily, using Q345R steel for the reactor—tough stuff that handles the heat. Dimensions? About 30 meters in length, 2.4 meters in width and 8 meters in height (for a double set), covering an area of about 50 meters by 8 meters. The total installed power is 190kW, and it operates smoothly without power fluctuations..

Here’s a quick specs breakdown in a table for clarity:

| Feature | Details |

| Capacity | 30 tons per day |

| Operating Temp | ≤650°C |

| Fuel for Startup | 400 kg (then zero during run) |

| Workers Needed | 2-3 |

| Lifespan | 10 years |

| Power Usage | 190 kW/h |

| Recovery Rates | Fuel oil 55-65%, carbon black 35-40%, combustible gas 3-5% |

What sets it apart? The anti-coking reactor spins to avoid buildup, extending life. Multilevel cooling maxes out oil yield. And that hot air heating with catalysts? It keeps temps low, reducing wear. No wonder it lasts a decade.

Picture this: In a traditional plant, you’d need a crew of 10 or more—feeding materials, monitoring temps, hauling out slag. Shifts drag on, errors creep in, costs balloon. But with fully continuous automation, it’s down to 2-3 workers. How?

Everything’s mechanized. Conveyors handle input; auto-slag systems dump carbon black without a hitch. Sensors track pressure and temps, adjusting on the fly. One guy oversees the control panel, another checks outputs. That’s it. No heavy lifting or constant babysitting.

From industry chats I’ve had, operators in places like Turkey—where a similar 15T unit runs—say it frees up staff for quality checks or sales. Less fatigue means fewer mistakes. For a 30T setup, this translates to slashing labor costs by 70-80%. You’re not just saving money; you’re building a leaner, safer operation.

Fuel bills can kill a waste processing gig. External gas or oil? Forget it after startup. This plant generates syngas—3-5% of output—and loops it back to the furnace. Startup takes 400 kg, then nada. Zero. It’s self-sustaining, like a closed-loop engine.

In practice, desulfurize the gas, pump it via vacuum, and burn it clean. No waste, no extra buys. Operators report cutting energy costs to zilch, turning what was a drain into a perk. Amid rising fuel prices, this edges out competitors stuck on external supplies.

Durability matters. This plant’s designed for the long haul—10 years of steady service. Why? Low-temp catalysts ease stress on parts. The rotating reactor fights coking, a common killer. Flame retardants use nitrogen blows for safety.

Real talk: In high-volume recycling, downtime hurts. But with this build, maintenance is straightforward—yearly checks, not overhauls. Users in export markets like Indonesia note it runs reliably, even in humid spots, thanks to enclosed seals. Invest once, reap for a decade.

High ops costs? Low efficiency? These hit hard. Fuel eats budgets; manual work slows output. Fully continuous tech tackles both. Zero fuel use post-startup drops expenses. Automation boosts speed—non-stop processing means higher daily yields.

Consider a mid-sized recycler bogged down by batch inefficiencies. Switching to this? They process more, spend less. Environmental perks seal the deal—no leaks, clean exhaust. It’s not hype; it’s proven in global installs, where firms see ROI in under two years through oil sales alone.

Look at high-volume tire recycling. A 30T fully continuous plant churns out steady oil, black, and steel. One news piece highlighted how it turns hazardous sludge into fuel with low emissions, high recovery. Another touted integrated pyrolysis-distillation for clean diesel from tires—full valorization.

In Turkey, a 15T version hums with syngas treatment, cutting waste while producing valuables. Spain and Malaysia sites echo this: efficient scaling, thanks to process-plus-equipment know-how. These aren’t one-offs; they’re patterns showing reduced costs, boosted outputs. For ESG goals, it fits the circular economy—waste in, resources out.

Before wrapping up, a nod to the folks behind this tech. Qingdao Xingfu Energy stands out as a top supplier of industrial boilers, pressure vessels, and waste tires & plastics pyrolysis systems. Since 2010, based in Qingdao, they’ve built a rep with 228 staff, including sharp engineers and welders. Spanning 70,500 square meters, they hold CE and ISO certs, exporting to 30+ countries like Poland and Korea. Their focus? Solid R&D for reliable gear that delivers.

Wrapping it up, automation via fully continuous pyrolysis isn’t just a trend—it’s a practical shift for waste pros. With a 30T/D plant, you cut labor to 2-3, nix fuel costs, and count on 10 years of service. It solves those efficiency woes head-on, turning waste into wins. If you’re in recycling, this could be your edge.

What makes a fully continuous pyrolysis plant more efficient than batch systems?

Fully continuous plants keep the process rolling without stops for loading or unloading, which means higher daily output and less downtime. For a 30T/D setup, this translates to steady recovery of fuel oil and carbon black, addressing slowdowns that batch methods often face.

How does the plant achieve zero fuel consumption during operation?

It uses syngas produced from the pyrolysis itself—about 3-5% of the output—to fuel the heating. After a quick 400 kg startup, it runs self-sufficiently, cutting out external fuel needs and lowering costs big time.

Can a fully continuous plant really run with just 2-3 workers?

Yep, thanks to automation like auto-feed conveyors and sensor controls. Workers mainly monitor panels and handle outputs, freeing up time and reducing the crew size compared to manual-heavy alternatives.

What’s the expected lifespan of a 30T fully continuous pyrolysis plant?

Around 10 years, built with durable materials and anti-wear features like low-temp catalysts. Real installs show it holds up well, even in demanding environments.

How does fully continuous technology help with environmental compliance?

The enclosed design prevents leaks, and multistage gas processing meets strict standards like Europe’s. It minimizes dust and emissions, making it a green choice for waste handling.