Running a waste tire or plastic recycling operation often comes with a big headache: skyrocketing fuel bills that eat into profits month after month. Diesel, natural gas—whatever you burn to keep the reactors hot, it adds up fast, especially with energy prices all over the place these days. But what if you could flip that script? Fully continuous pyrolysis plants are making it real, turning the process into an energy self-sufficient loop where, after a quick startup, your fuel cost drops to zero. No more shelling out for external energy. The system feeds itself with its own byproducts. For recyclers tired of those ongoing expenses, this isn’t just a nice-to-have—it’s a game-changer that keeps more money in your pocket.

At the heart of it, pyrolysis breaks down waste into fuel oil, carbon black, steel wire, and syngas in a high-heat, no-oxygen setup. The fully continuous version runs non-stop, feeding material in steadily and pulling products out without pauses. But the real standout? That syngas— the flammable gas produced during cracking—gets cleaned and recycled right back into the furnace. It’s like the plant becomes its own power source, solving the pain of constant fuel purchases head-on.

Pyrolysis has been around for years, turning trash like old tires and plastics into usable stuff. Heat them up, crack the molecules, collect the goodies. Simple enough. But traditional setups—batch or semi-continuous—often rely on outside fuel the whole time. You fire up the burners with gas or oil, and they stay on, guzzling away. In a typical day, that might mean hundreds of dollars just to keep things going, scaling up with bigger loads.

Operators I’ve heard from in the field complain about it constantly. One guy running a mid-sized plant said his monthly fuel tab hit five figures before switching tech. Volatility in oil prices makes budgeting a nightmare. And in regions where energy is scarce or pricey, it can kill a project’s viability outright. Fully continuous systems tackle this directly by harnessing syngas for heat, cutting that external dependency to nothing after ignition.

Here’s where it gets interesting. In a fully continuous pyrolysis plant, about 3-5% of the output is syngas—a mix of gases that’s highly flammable. Instead of venting or flaring it off (wasteful and polluting), the system captures it all.

The process flows like this:

Startup? Yeah, you need around 400 kg of fuel to get temperatures up. But once cracking starts and syngas flows—usually within hours—external fuel shuts off. Zero from then on. Real runs show this holds steady over 24/7 operation.

Take a 30-ton-per-day equipment for processing waste tires (chopped to 20mm) as an example. It can produce 55-65% fuel oil, 35-45% carbon black and 3-5% combustible gas per day. All the heat supply is provided by its own gas. There is no need to replenish fuel daily or sign a long-term gas supply contract, which greatly increases the profit margin.

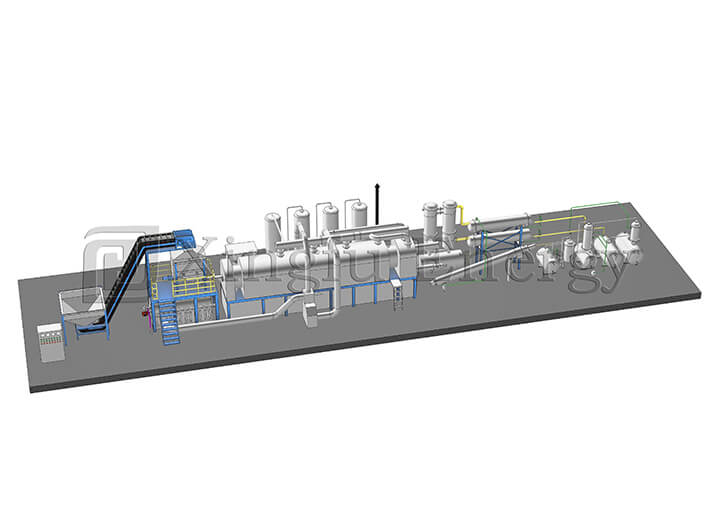

Diving into a solid example, the 30T fully continuous model packs features that make this zero-fuel reality reliable.

Quick look at key numbers:

| Feature | Details |

| Capacity | 30 tons/day |

| Startup Fuel | 400 kg |

| Operating Fuel | 0 kg (syngas recycled) |

| Syngas Yield | 3-5% |

| Total Power | 190 kW |

| Workers Needed | 2-3 |

| Lifespan | 10 years |

| Oil Recovery | 45-50% |

Built with Q345R steel, it uses a rotating reactor to fight coking—keeps things clean inside for consistent gas production. Low-temp catalysts ease the heat load, and nitrogen flame retardants add safety. Enclosed design means no leaks, dust controlled, emissions hitting tough standards like Europe’s without extras.

Think about a recycler in a high-energy-cost area. Before, fuel might claim 20-30% of operating expenses. Switch to fully continuous? That line item vanishes post-startup. Suddenly, you’re selling more oil without the offset.

From installs I’ve seen referenced—like a 15T unit in Turkey with syngas treatment—it runs smooth, operators noting fuel savings as the biggest win. Another in Malaysia, 20T scale, handles steady loads while looping gas back. No interruptions for refueling, just consistent output. In Bulgaria or Spain, similar stories: lower bills, predictable costs.

One operator shared how it transformed his bottom line. Paid back the upgrade faster through avoided fuel buys alone. And with oil yields high, the self-produced fuel oil becomes pure profit. It’s not theoretical—global projects prove it.

Some plants flare syngas or use partial recycle. Not ideal. Flaring wastes energy and can ding emissions. Partial means still buying some fuel. Fully continuous goes all-in: capture, clean, burn every bit.

Benefits stack up:

In volatile markets, this locks in stability. Energy prices spike? You’re unaffected.

Skeptics ask: Does it really hit zero? Or is syngas enough? Data says yes—3-5% covers heat needs in well-designed systems. Downtime for cleaning? Minimal, thanks to anti-coking rotation.

Another worry: Startup reliability. But with hot air setups and catalysts, it ramps quick. Long-term? 10-year lifespan from durable builds.

For folks bogged down by batch fuel hogs, this shifts the economics. More throughput, no energy drain.

Beyond fuel, these plants automate heavily—conveyors feed, sensors monitor, auto-discharge handles solids. Just 2-3 workers oversee. Pair that with zero fuel, and ops costs plummet.

High-volume tire yards or plastic recyclers see the appeal. Turn waste streams into revenue without the energy anchor.

A quick shoutout to the team making this tech accessible. Qingdao Xingfu Energy has been a go-to supplier for industrial boilers, pressure vessels, and waste tire/plastic pyrolysis systems since 2010. Based in Qingdao, they’ve grown with 228 staff, strong engineering focus, and a 70,500 square meter setup. Holding CE, ISO9001, and pressure vessel certs, they export to over 30 countries like Indonesia, Korea, Poland, and Malaysia. Their emphasis on R&D delivers solid, field-proven equipment.

Bottom line, achieving energy self-sufficiency in pyrolysis isn’t hype—it’s practical with fully continuous designs recycling syngas for heat. Zero operating fuel means crushing those persistent cost pains, freeing up cash for growth. If high energy bills are holding your recycling operation back, this approach could redefine your setup.

How does a fully continuous pyrolysis plant reach zero operating fuel cost?

It recycles the 3-5% syngas produced during processing—cleans it and burns it back in the furnace. After 400 kg startup fuel, no external energy needed.

Is the syngas output enough to sustain heating in a fully continuous system?

Absolutely, in models like 30T/D, the 3-5% yield covers all heat requirements reliably, as seen in ongoing installs.

What happens to fuel costs long-term with fully continuous pyrolysis?

They drop to zero post-startup, eliminating one of the biggest ongoing expenses in waste processing.

Can fully continuous plants maintain zero fuel even at full capacity?

Yes, the closed-loop syngas system scales with load, providing steady self-heating without extras.

Why is energy self-sufficiency a big deal for fully continuous pyrolysis operators?

It directly cuts out volatile fuel expenses, making operations more profitable and predictable in tough markets.