Folks in the waste tire and plastic recycling business know the drill. You run pyrolysis to break down scrap into crude oil, carbon black, and some gas. That’s a solid start. It pulls value from stuff headed to landfills. But that crude oil? It’s rough. Dark, smelly, full of impurities. Burn it straight, and you deal with low efficiency, clogged engines, or even environmental headaches.

Enter oil distillation. This step refines the pyrolysis oil into clean petrol and diesel fractions. Suddenly, you’ve got fuels that meet real-world specs—ready for generators, boilers, or even vehicles in some markets. Pair the two processes, and you build a full loop. Waste in one end, marketable products out the other. That’s the circular economy in action. It boosts waste valorization big time. Companies tracking ESG reports love it too—lower emissions, better resource use, stronger sustainability scores.

Operators often hesitate. Setting up separate systems sounds complicated. High upfront costs, mismatched equipment, ongoing tweaks. What if one supplier handled it all? A true turnkey setup from pyrolysis through distillation. Simpler ops, tighter costs, smoother runs.

Many plants stick to pyrolysis alone. They sell crude oil cheap or burn it on-site. Fine for small outfits, but it caps profits. Crude fetches low prices—maybe half what refined diesel brings.

Then there’s the tech side. Pyrolysis outputs vary with feedstock—tires one day, plastics the next. That oil needs consistent refining to hit quality marks. Mismatched distillation gear leads to poor yields or downtime.

Costs add up fast. Separate vendors mean double shipping, custom fittings, extra training. Maintenance? Split between teams. One breakdown ripples through the chain.

Real-world example: A mid-sized recycler in Asia ran a 15-ton pyrolysis unit. Crude oil piled up. They bolted on a third-party distiller later. Integration took months—piping rewrites, control mismatches. Lost production time ate into margins.

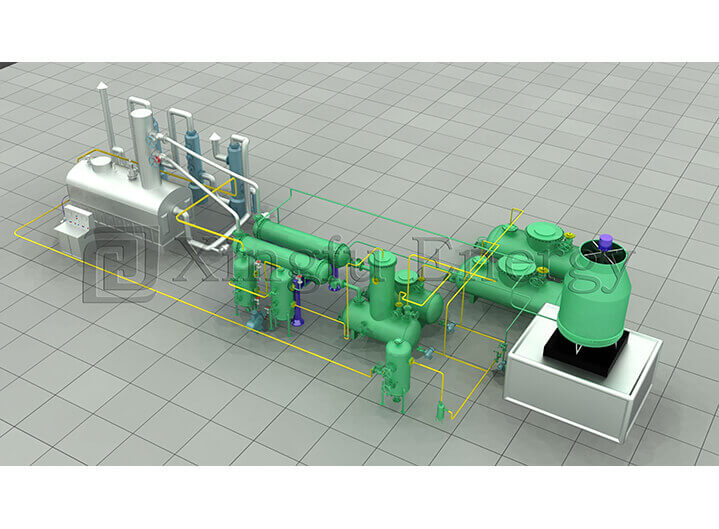

Picture this: One complete line. Pyrolysis feeds straight into distillation. No middle storage hassles, no quality drops from exposure.

Modern setups do just that. Start with continuous or semi-continuous pyrolysis for steady crude output. Then pipe it hot to the distillation reactor. Dewater first, heat gently, gasify, cool selectively. Petrol fraction off the top, diesel next. Residue handled clean.

Take a 20-ton distillation plant matched to pyrolysis output. It handles plastic or tire oil, waste lube, even sludge-derived crude. Batch processing keeps it flexible.

Key perks show up quick.

In practice, plants report 20-30% lower operating costs versus pieced-together lines. Startup faster too—weeks, not months.

This chain turns variable waste into consistent fuels.

Consider a 20-ton-per-batch oil distillation plant. It’s built for pyrolysis crude from tires or plastics.

It runs at normal pressure, tops out around 650°C. Hot air circulation avoids direct flames on the reactor—extends life, boosts safety.

Power draw? Just 20 kW/hour once going. Compact footprint too—fits in a modest shop.

Outputs break down like this:

| Fraction | Typical Yield | Notes |

| Petrol | 15-20% | Light fraction, quick condensing |

| Diesel | 70-75% | Main product, high-quality fuel |

| Flammable Gas | 2-5% | Recycled for heating |

| Residue | 10-18% | Minimal, often reusable |

Total oil yield: 90%. Full conversion means nothing wasted.

Catalysts tuned in-house improve flow and clarity. Automatic welding and X-ray checks ensure no weak spots.

Plants like this pair seamlessly with upstream pyrolysis—same supplier designs for perfect fit.

Beyond the tech, integration supports bigger goals.

Waste valorization shines. Every ton of scrap tires yields fuel worth far more refined. Carbon black sells to rubber makers; steel to scrap yards.

Circular economy? Check. Keeps materials looping, cuts virgin oil demand.

ESG reporting gets a lift. Cleaner fuels mean lower downstream emissions. Auditable chain from waste to product.

One operator in Europe scaled from batch pyrolysis to integrated line. Oil sales jumped 40%. Payback in under three years. Crew stayed small—four hands total.

Qingdao Xingfu Energy Equipment Co., Ltd. calls Qingdao City home in Shandong Province. Founded in 2010, it’s grown into a go-to supplier for industrial boilers, pressure vessels, and waste tire & plastic pyrolysis systems.

With over 200 team members—including dozens of engineers—they handle everything in-house. Research, design, manufacturing, even installation support. Certifications like CE and ISO9001 back their quality. Products ship to more than 30 countries, earning solid feedback along the way.

They offer full-chain solutions, from pyrolysis plants to oil distillation units. That means matched equipment for seamless integration.

Standalone pyrolysis gets you started. But adding distillation closes the loop. An integrated, turnkey solution simplifies everything—fewer headaches, lower costs, higher returns.

It aligns with circular economy principles, maximizes waste valorization, and strengthens ESG profiles. For recyclers ready to level up, this path turns waste streams into real revenue drivers.

One partner handling the whole value chain makes it straightforward. Cleaner fuels, better margins, sustainable ops. That’s the future of waste-to-energy.

It connects the processes end-to-end under one roof. Pyrolysis crude flows straight to distillation—no extras needed. Cuts setup time and costs while boosting overall efficiency.

Shared heating, power, and controls trim bills 20-30%. Higher refined oil prices add upside. Plants often see payback quicker than separate buys.

Yes—flexible designs like 20-ton batches adjust to tire or plastic crude. Catalysts and hot air systems keep yields steady, around 90% oil recovery.

It promotes waste valorization and circular flows. Refined fuels burn cleaner. Full traceability from scrap to product helps document sustainability gains.

Not at all. Unified controls and matched parts make it simpler. Fewer vendors to chase, routine checks cover the line.