Oil sludge builds up quickly in the oil business. Picture drilling rigs, refineries, or those big tank cleanouts. You end up with thick, greasy gunk that’s hard to deal with and really bad for the environment. It’s labeled hazardous waste, and for darn good reason. But imagine turning that mess into actual fuel you can use. That’s exactly what oil sludge pyrolysis does. It heats the sludge in a sealed space with no oxygen, breaking it down into fuel oil, gas, and solids that are much easier to handle.

If you’re an operator or environmental manager in energy, you face this stuff every day. You’re hunting for ways to slash disposal costs, stay ahead of tough rules, and maybe even make a few bucks. This guide takes you through the oil sludge pyrolysis process, step by step. It sticks to real-world use, nothing fancy.

Oil sludge is the nasty leftover from producing and refining oil. It’s a mix of heavy hydrocarbons, water, dirt like sand or clay, and sometimes metals. One single tank bottom can hold thousands of tons.

If you ignore it, it poisons soil and water. Trucking it to landfills costs a fortune—often hundreds per ton. Plus, there’s always the chance of spills on the road. Rules are getting stricter everywhere. Companies need better options.

Pyrolysis gives a smarter choice. It turns the hydrocarbons in oil sludge into fuel by heating it carefully, without any burning. That means no dioxins, very low emissions, and products you can sell or reuse.

The process isn’t too tricky. But doing it right changes everything. Here’s how it goes.

Raw oil sludge comes in all kinds. Some is runny, almost like liquid. Others are thick and loaded with water. First, you dry it out and sometimes break the emulsions to pull off free water. This cuts down on energy later. It also boosts yields. Many plants use centrifuges or simple heaters for this.

The treated sludge feeds into the reactor. Temperatures rise to 400-550°C, with zero oxygen. Bonds snap. Long chains of hydrocarbons crack into shorter ones.

That’s when the fuel appears. Vapors lift off—mostly oil and gas that won’t condense. Solids remain as char.

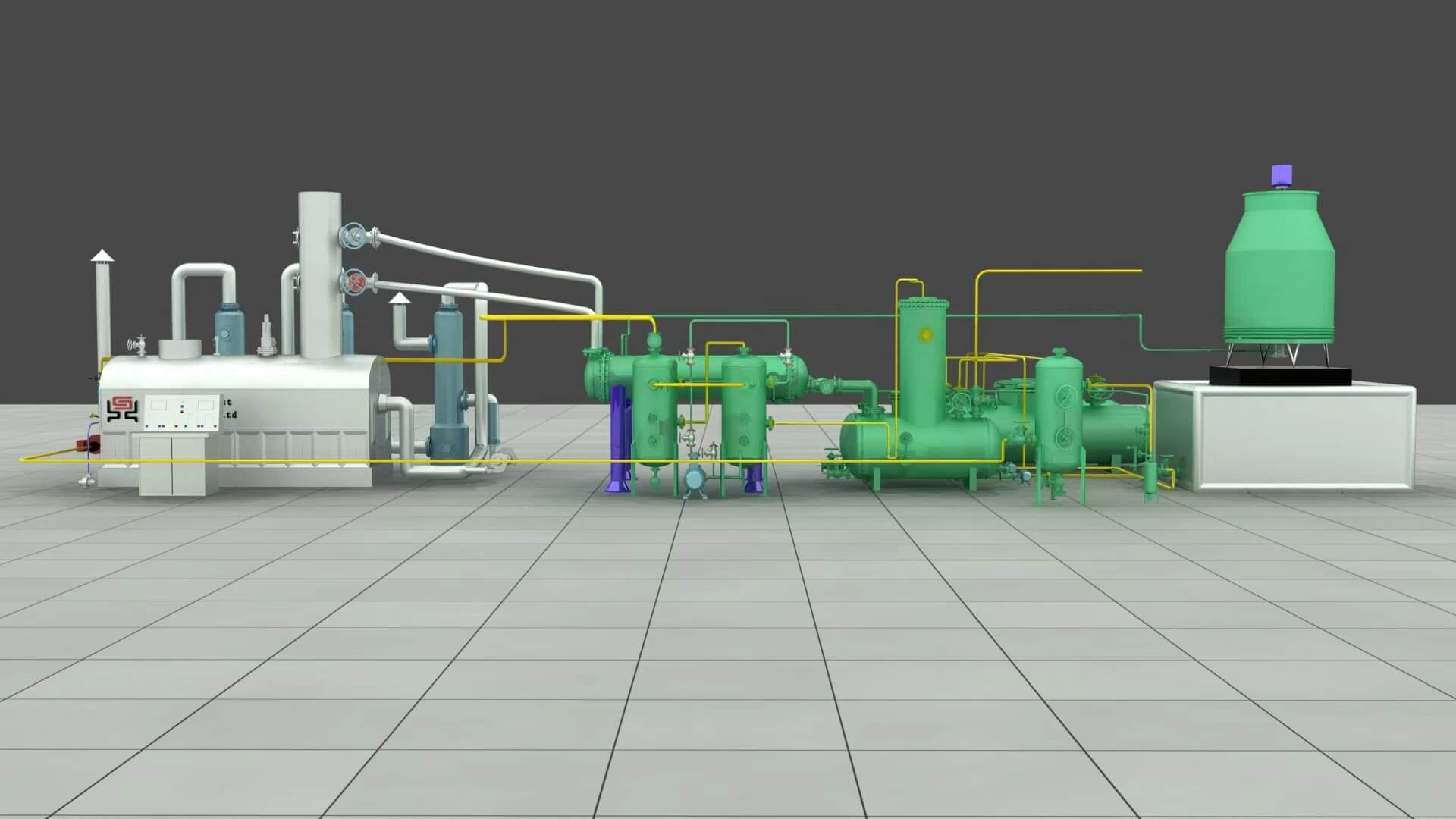

Today’s setups run batch or continuous. Continuous models fit big operations best. They handle tons daily without stopping all the time.

Vapors cool down in condensers. The oil turns liquid and collects. Leftover gas can fire up the system itself. In good designs, this covers up to 80% of energy needs. No big fuel bills from outside.

The remaining char comes out. In top systems, it holds hardly any oil—usually under 0.3%. That means nearly complete recovery. The solids are simpler to dispose of or reuse, maybe in roads or bricks.

Anyone who’s operated a pyrolysis plant knows the pain points. Sludge clings to reactor walls. It bakes onto hot spots, drops efficiency, and forces shutdowns often.

Plenty of older units fight this battle. They need cleaning every few weeks.

Newer systems fight back smartly. They come with built-in scrapers. These devices spin steadily and wipe the inside walls clean. No sticking, no baking. Plants run for months straight.

They also take on tough feeds easily. Lots of sand? Metal bits? Changing moisture? It doesn’t faze them. Yields stay consistent.

Take a real case: A medium refinery faced 20 tons of sludge each day. They added pyrolysis. Soon, they pulled enough fuel oil to cover most running costs. What used to be a headache turned into extra income.

On the environmental side, pyrolysis keeps hazardous waste out of landfills. The low-oil char often counts as regular waste. Emissions stay in check with basic scrubbers and filters.

Money-wise, plants often pay for themselves in 2-4 years. It depends on size and local fuel prices. The recovered oil sells as heavy fuel or goes to distillation for diesel. Gas handles heating. Some folks even sell the char.

Qingdao Xingfu Energy, based in Qingdao City, Shandong Province, has built a solid reputation since 2010 as a supplier of industrial boilers, pressure vessels, and pyrolysis systems for waste tires, plastics, and oil sludge. With a large team of engineers and skilled welders, plus certifications like CE and ISO9001, they’ve delivered reliable equipment to over 30 countries. Their focus on practical, high-uptime designs comes from years of hands-on experience in thermal processing.

Oil sludge doesn’t need to stay a pricey problem. With fuel pyrolysis, it turns into something useful—better handling, valuable products, and true savings. The tech has come a long way. New features keep reactors running smooth and grab almost every drop of oil. For sites drowning in sludge, this offers a clear path: less waste, lower risks, and even some profit.

It’s a heat-based method. It warms oil sludge without oxygen. This breaks it into fuel oil, burnable gas, and solid leftovers. The fuel pyrolysis step pulls out hydrocarbons that would just go to waste.

Yields frequently hit 85% or more from the hydrocarbon portion. It varies with sludge quality. Top systems leave under 0.3% oil in the solids.

Oil sludge loves to stick and harden inside hot reactors. That leads to stops and repairs. Scraper tools stop buildup. They let the plant run steady and long.

Definitely. It cuts hazardous waste volume. Outputs stay low-emission. Leftover solids often become non-hazardous. It’s far better than dumping or burning.

Yes, no doubt. Versatile setups take on refinery tank sludge, oily drill waste, anything. They adjust to different mixes and keep performing well.