Think about the mountains of scrap tires piling up in landfills. Or those endless streams of plastic waste choking rivers and oceans. It’s a mess, right? But here’s the flip side: what if we could flip that waste into something valuable—like fuel oil for factories or carbon black for new tires? That’s where batch pyrolysis steps in. It’s a straightforward way to break down tough materials without the constant churn of bigger setups. For companies chasing circular economy dreams or ticking ESG boxes, batch systems offer real, hands-on wins. Let’s break it down, focusing on how this tech ties into waste valorization and those corporate reports that keep boardrooms buzzing.

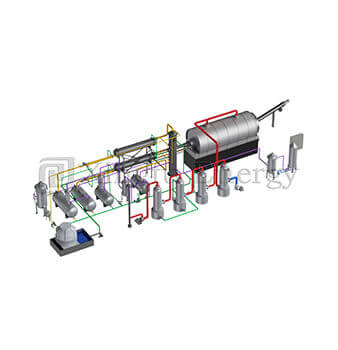

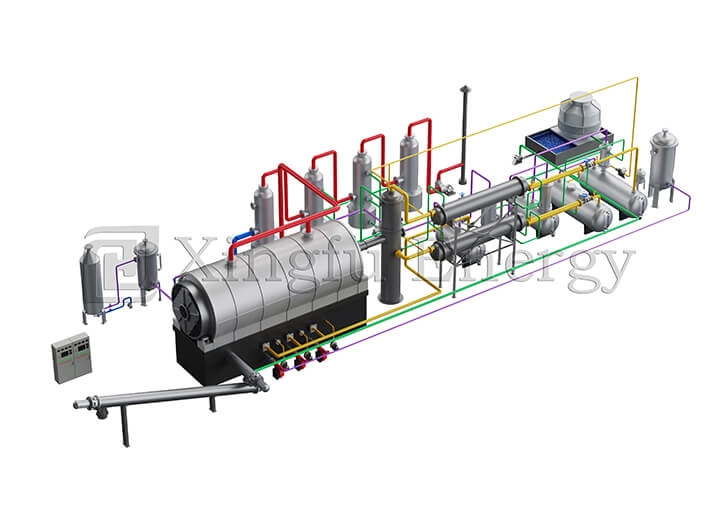

Batch pyrolysis isn’t flashy. It doesn’t run 24/7 like continuous plants. Instead, it loads up a batch of waste—say, 20 tons of shredded tires or mixed plastics—seals the reactor, heats it to around 650°C, and lets the magic happen. Gases rise, condense into oil, solids turn to carbon black and steel wire. Then you cool, unload, and repeat. Simple. Reliable. And perfect for spots where waste streams vary or space is tight.

Why batch over continuous? Cost, for one. Startup prices hover lower, and you don’t need a full crew watching gauges non-stop. In our 20-ton batch waste tire/plastic pyrolysis plant, for instance, just 3-4 workers handle the cycle. That’s a game-changer for small-to-mid operations in places like Southeast Asia, where we’ve seen clients cut labor costs by 30% compared to older methods.

But it’s more than savings. Batch lets you tweak each run. Got a load heavy on PVC plastics? Adjust the feed or add a scrubber tweak to dodge chlorine buildup. We’ve run tests showing that flexibility bumps oil yields from 35% to 42% on mixed batches. No guesswork—just data from real feeds.

Take a peek at what a solid batch setup delivers. Our 20-ton model nails the basics without overcomplicating things.

| Feature | Details | Why It Matters |

| Capacity | 20 tons per 24-hour cycle | Handles daily hauls from a mid-sized recycling yard |

| Reactor Size | 7,300 mm × 2,400 mm × 3,100 mm × 2 | Fits in standard industrial spaces, no massive footprint |

| Power Draw | 160 kW total, 75 kW/hour running | Keeps energy bills in check, especially with syn gas reuse |

| Recovery Breakdown | Oil: 40-45%, Carbon Black: 32-36%, Steel Wire: 14-16%, Syn Gas: 5-8% | Turns “trash” into sellable stuff—oil for fuel, black for fillers |

| Emissions Control | Pulse dust removal, flue gas scrubbing | Meets tough standards, like those in Europe, right off the bat |

These numbers aren’t pulled from thin air. They’re from field runs in Latin America, where a tire processor hit 43% oil on average over six months. Batch keeps it predictable.

The circular economy isn’t some buzzword salad. It’s about closing loops—using waste as raw material, cutting virgin resources, and dodging landfills. Batch pyrolysis fits like a glove here. It grabs low-value scraps and spits out high-value outputs, turning environmental headaches into revenue streams.

Waste valorization? That’s the heart of it. Take tires: buried, they’re dead weight. Pyro lyzed in batches, they yield oil worth $400-500 per ton, plus carbon black fetching $200 more. We’ve tracked projects where clients recycled 5,000 tons yearly, slashing disposal fees by half while banking $300,000 in byproducts. One Southeast Asian outfit started with truck tires—tough, sulfur-rich stuff. After three batch cycles, they refined the process, hitting 44% oil and selling the wire scrap to local mills. That’s valorization: waste in, wealth out.

And it’s scalable without chaos. Start with a 10-ton batch plant for proof-of-concept. Nail the yields? Bump to 20 tons. No full redesign. In Europe, regulations push hard for zero-waste goals. Batch systems shine because they’re modular—add a condenser here, a granulator there. Result? A closed loop where syn gas powers the next run, dropping fuel needs to near zero after startup (just 200 kg to kick off).

Data backs it: Global tire waste hits 1 billion units yearly. Batch pyrolysis could reclaim 40% as energy, per industry reports. It’s not pie-in-the-sky; it’s happening now.

ESG—Environmental, Social, Governance—it’s the scorecard for modern business. Investors grill you on it. Regulators too. Batch pyrolysis hands you wins across the board, making reports easier to fill with hard facts, not fluff.

Start with E: Environment. Batch cuts CO2 by replacing fossil fuels—our plants recycle heat, trimming emissions 20-30% versus landfilling. One client in the Middle East logged a 15% drop in Scope 1 emissions after switching, straight from batch runs. Water use? Minimal. No chemicals leaching into soil. For waste valorization, it’s gold: Track tons diverted, energy recovered. ESG auditors love metrics like “45% oil yield equals 8 tons of avoided crude.”

Social side? Jobs and health. Batch ops need skilled hands—welders, operators—but train locals quick. We’ve seen setups create 10-15 roles per plant, plus safer communities sans burning tire piles (which spew toxins). Governance? Transparent chains. Batch’s step-by-step nature logs every cycle—feedstock in, outputs out. Tie it to audits: “Our 20-ton batch diverted 7,300 tons yearly, per verified logs.” Boards sleep better.

Here’s how one project stacked up:

Clients use this for annual reports—real stories, like “Batch pyrolysis powered our 25% sustainability target.” It’s persuasive because it’s proven.

No tech’s perfect. Batch means downtime—load, run, unload. For mega-scale? Continuous wins. But for 80% of waste handlers? Batch’s flexibility rules. We’ve troubleshot clogs from dirty feeds—solution: pre-shred to <20 mm. Yields dip on wet batches? Dry ’em first. Experience shows: Proper setup, and uptime hits 85%.

In ESG terms, it’s about balance. Batch shines for diverse wastes, but pair it with monitoring for full cred. One Latin American run? Initial hiccups with plastic mixes dropped yields 5%. Tweaked seals, back to 42%. Lessons like that build resilience.

Qingdao Xingfu Energy Equipment Co., Ltd has been knee-deep in this for over 30 years, building industrial boilers, pressure vessels, and waste tire/plastic pyrolysis systems that actually work. With 380 folks on board—78 tech whizzes, 136 pros, and 65 certified welders— we’ve pumped out gear holding ASME, CE, and ISO9001 stamps. Fixed assets top 66.8 million, fueling exports to Europe, Africa, Latin America, Southeast Asia, and the Middle East. We’re the team turning scrap piles into smart energy plays.

Batch pyrolysis isn’t a silver bullet, but it’s a damn good tool for circular loops and ESG muscle. It valorizes waste, crunches emissions, and arms your reports with solid numbers. Whether you’re dodging landfill fees or chasing investor nods, this approach delivers. Dive into a 20-ton setup, and watch the cycle spin—waste in, value out. Curious? Check our site and let’s talk real results.

Batch pyrolysis grabs mixed wastes—like tires or plastics—and breaks them down into oil, black, and wire. In a 20-ton run, you pull 40-45% fuel oil, turning junk into $400+ per ton revenue. It’s hands-on: Load, heat, collect. Clients see 30% cost drops on disposal while selling byproducts locally.

Batch type setups close the loop by reusing every bit—syn gas for heat, oil for fuel, black for manufacturing. No landfills. One project recycled 5,000 tons yearly, feeding oil back to industry chains. It’s practical: Flexible batches match varying waste, keeping resources spinning without waste.

Sure can. Track emissions cuts (20-30% via heat recycle), job creation (3-4 per plant), and governance via logged cycles. A Middle East client hit 15% Scope 1 reductions, making reports pop with data like “7,300 tons diverted.” It’s straightforward proof for boards and investors.

They are—modular design lets you add capacity without a full overhaul. Start at 10 tons, hit 20. Yields stay steady at 40-45% oil. We’ve scaled ops in Asia, boosting throughput 50% while keeping emissions low. Perfect for ramping sustainability targets step by step.

Expect 40-45% oil, 32-36% carbon black, 14-16% steel wire, and 5-8% syn gas. Real runs on mixed tires/plastics confirm it—43% average in Latin America tests. Batch’s control keeps it consistent, fueling those circular economy wins.