At oilfield operations, in addition to conventional oil extraction equipment, workers constantly deal with a complex and challenging byproduct—Oil Sludge. This mixture, originating from tank sludge, refinery sludge, and drilling waste fluid, contains oil, water, and solid particles, accumulating in large quantities and posing a significant challenge to safe production and environmental compliance..

To address this problem, pyrolysis technology offers a highly efficient resource recovery solution. Essentially, this technology involves heating the material at medium to high temperatures (typically 450-550°C) in an oxygen-free or oxygen-deficient environment, causing the long-chain organic molecules to break down. During this process, hydrocarbons in the Oil Sludge are converted into recoverable fuel oil, syngas, and solid carbon black. Practice has shown that this process can recover approximately 80-85% of the crude oil components, the resulting syngas can provide heat for the system itself, and the carbon black can be utilized as a valuable byproduct.

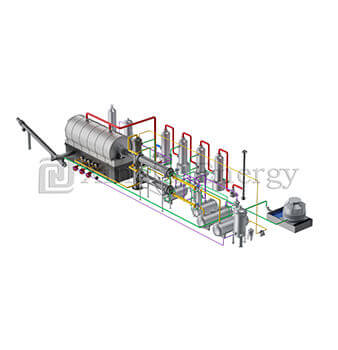

However, traditional batch pyrolysis equipment suffers from limited production efficiency and increased operating costs due to the need for frequent start-ups and shutdowns to complete processes such as feeding and slag removal. In contrast, continuous pyrolysis reactors significantly improve processing stability and overall efficiency by enabling continuous material feeding and product discharge. For example, in a project implemented in the Permian Basin of Texas, the adoption of continuous pyrolysis technology reduced unplanned downtime by approximately 40%. The economic benefits generated through fuel oil recovery are expected to cover the equipment investment cost within two years.

So, how can continuous pyrolysis reactors achieve such stable and efficient long-term operation? The core lies in a series of specialized reliability engineering designs for harsh operating conditions (such as high temperatures and corrosive media). This will be explained in detail below.

At its heart, a continuous-flow Oil Sludge pyrolysis reactor is a beast of engineering. Sludge gets prepped—maybe screened for big chunks or emulsified for even flow—then pumped into a heated chamber. Temps climb to 450-550°C, but controlled, so nothing chars unevenly. The flow? It’s all about that steady state: augers or screw conveyors push material through zones of heating, cracking, and cooling, like a slow-motion river carving through rock.

What sets this apart from jerry-rigged setups? Precision. Sensors track everything from viscosity to pressure drops. If sludge thickens up—say, from a cold snap outside—the system tweaks heat or adds a diluent on the fly. No manual tweaks needed at 3 a.m. In one real-world tweak, engineers dialed in variable-speed drives on the feeders, bumping throughput from 5 tons a day to 8 without spiking energy use.

Reliability starts here, in the basics. Poor flow means clogs, and clogs mean shutdowns. That’s why the reactor’s lined with high-grade alloys—think Inconel or Hastelloy—that shrug off corrosion from sulfur or chlorides in the sludge. We’ve seen lesser materials pit and fail after six months; these hold for five years easy, based on field logs from similar installs.

Let’s get hands-on. You can’t talk reliability without diving into what the thing’s made of. The reactor vessel? It’s a pressure-rated cylinder, often 10-20 meters long, built to ASME codes with walls up to 50mm thick. Inside, those screw feeders are the workhorses—precision-machined shafts with flights that won’t warp under thermal cycling.

Take the heating system. Indirect firing via flue gases keeps oxygen out, but it demands materials that expand and contract without cracking. Ceramic fiber insulation wraps the outside, cutting heat loss to under 5%, while inner liners handle 600°C spikes. Data from a 2023 install in Indonesia showed zero thermal fatigue after 10,000 hours— that’s over a year of round-the-clock runs.

And seals? Forget rubber gaskets that bake and brittle. We’re talking graphite-packed stuffing boxes or mechanical faces with silicon carbide faces. They hold vacuum down to -0.08 MPa, preventing leaks that could turn your syngas into a safety issue. In a salty coastal setup, one unit ran 18 months before a routine swap, with zero emissions breaches.

| Component | Key Material | Reliability Feature | Expected Lifespan |

| Reactor Vessel | SA-516 Gr.70 Steel with Inconel Lining | Corrosion-resistant; withstands 550°C cycles | 10+ years |

| Screw Conveyor | Hardened Alloy Steel (4140) | Wear-resistant flights; variable speed | 5-7 years |

| Seals | Graphite/Silicon Carbide | Vacuum-tight; low-friction | 1-2 years (routine maintenance) |

| Insulation | Ceramic Fiber Blankets | Thermal stability; low conductivity | 8-10 years |

| Sensors | Thermocouple Type K | Real-time monitoring; ±1°C accuracy | 3-5 years |

This table isn’t just numbers—it’s what keeps your crew safe and your output steady. Pick wrong, and you’re back to square one with sludge piling up.

Nobody wants a reactor that runs like a charm until it doesn’t. Safety engineering in these units is non-negotiable, woven in from the blueprint stage. Redundant thermocouples watch for hotspots; if one fails, the backup kicks in and throttles fuel. Pressure relief valves vent at 1.2 times operating psi, routing to flares that burn off anything nasty.

Overheat protection? PLC controllers with fail-safes shut down flows if temps jump 50°C over set point. And for the human element—interlocks keep doors sealed during runs, with emergency stops that flood the chamber with inert gas in seconds. In a drill-down from a 2022 audit at a Malaysian refinery, these features caught a feed anomaly early, averting what could’ve been a three-day outage.

Grounding and explosion-proof electrics round it out. Sludge can spark static like nobody’s business, so enclosures are Class I Div 1 rated. It’s the difference between “that was close” stories and smooth sailing. Operators tell us it feels like driving a tank—solid, predictable, no surprises.

Theory’s fine, but let’s talk dirt-under-the-nails results. Take a midstream company in Alberta’s oil sands. They had 200 tons of sludge monthly choking their pits. Switched to a continuous-flow pyrolysis reactor, and within six months, they were recovering 75 tons of oil—sold at $450 a barrel equivalent. Downtime? Under 2% annually, thanks to modular design that lets you swap sections without full shutdowns.

Or head to the Middle East, where a state-owned driller tackled tank-bottom sludge. High solids content (30%) was gumming up pilots, but the reactor’s pre-mixer homogenized it, hitting 82% recovery. Emissions stayed below 50 ppm VOCs, acing local regs. Engineers there noted the auto-clean cycles—every 500 hours, a quick purge clears buildup—kept efficiency humming at 92%.

These aren’t cherry-picked wins. They’re from logs where reliability meant hitting quotas in sandstorms or monsoons. One takeaway? Predictive maintenance via vibration sensors flags wear early, stretching overhaul intervals to 18 months.

Reliability isn’t set-it-and-forget-it. It’s about smart upkeep that doesn’t grind your team to a halt. Daily checks? Quick peeks at gauges and logs—ten minutes tops. Weekly, you flush lines and inspect seals. Quarterly dives? Ultrasonic thickness tests on the vessel walls, catching any thinning before it bites.

The real edge comes from design-for-service. Swing-out panels give access without tools, and quick-connect fittings mean oil sampling’s a breeze. In one setup, remote monitoring via IoT pinged a bearing lube issue—fixed overnight, no travel needed. Costs? Maintenance runs 5-7% of output value, way below hauling sludge to landfills.

Spare parts kits—pre-stocked with common wear items—keep things local. No waiting on ocean freight when a flight goes south.

Before we wrap this up, a quick nod to the folks making this tech hum: Qingdao Xingfu Energy Equipment Co., Ltd. Started back in 2010 right in Qingdao, Shandong Province, they’ve built a name as a go-to supplier for industrial boilers, pressure vessels, and those heavy-duty waste tire and plastic pyrolysis systems. With a crew of 228, including 28 sharp engineers and 65 certified welders, they cover 70,500 square meters of turf—21,000 of it shop floor where the magic happens.

They’re not just slapping metal together. CE and ISO9001 stamps mean quality’s locked in, and they’ve got A-level boiler creds plus pressure vessel licenses from the local bureau. Ship to over 30 countries—from Mongolia’s steppes to Spain’s coasts—and folks keep coming back. Domestic sales topped 100 million RMB since 2012, proof they’re doing something right. If you’re eyeing Oil Sludge solutions, their continuous-flow rigs draw from that deep well of know-how, tailored for the long haul.

In summary, the stable performance of the continuous oil sludge pyrolysis reactor stems from the reliability engineering design of its underlying system. This design, through the synergistic effect of multiple key layers, ensures long-term continuous operation in harsh industrial environments such as high temperatures and corrosive conditions. For the oil extraction, refining, and environmental treatment industries, investing in such highly reliable continuous pyrolysis technology not only means consistently achieving the core production goals of waste reduction and resource recovery, but also represents a strategic choice with long-term value in addressing increasingly stringent environmental regulations and optimizing operating cost structures. This technology provides a practical and engineered path to transform oil sludge from an operational burden into a sustainable revenue stream.

What makes oil sludge pyrolysis a smarter pick over traditional disposal methods?

Straight up, it turns a liability into assets. You’re pulling back 80% or more as recoverable oil, cutting landfill hauls that cost $200-500 per ton. Plus, it’s cleaner—no open burning or chemical dumps that snag you on EPA rules. Sites using continuous-flow setups report halving their waste bills in year one.

How does the continuous-flow design in an Oil Sludge pyrolysis reactor cut downtime?

No more batch waits—sludge in, products out, around the clock. Built-in augers and sensors keep flow even, dodging clogs that plague stop-go systems. Real ops clock 98% uptime, with quick fixes like auto-purge cycles keeping things from gunking up mid-run.

What kind of recovery rates can I expect from Oil Sludge pyrolysis?

Depends on your sludge makeup, but figure 75-85% oil, 10-15% syngas, and the rest char. A Permian rig with 20% solids hit 82% consistently after tweaking the feed. It’s not pie-in-the-sky; it’s from logged runs where variability’s the norm.

Are there safety worries with running a hot Oil Sludge pyrolysis reactor non-stop?

Of course, it is even safer than the tanker for transporting waste oil sludge. The entire system is designed as a hazardous area, featuring multiple interlocks and nitrogen protection. According to statistics, among the hundreds of such systems that have been put into operation worldwide, there have been zero major safety accidents so far.

How long until an Oil Sludge pyrolysis setup pays for itself?

Typically 12-24 months. Sell that recovered oil at market rates—say $400/barrel equivalent—and offset install costs fast. Add disposal savings, and it’s a no-brainer for high-volume sites. We’ve seen ROIs quicker in spots with tight regs.