You’ve just pulled 4,000 liters of dark, smelly pyrolysis oil off your reactor. It’s loaded with value, but right now it’s too heavy, too sulfury, and too watery to sell as decent diesel. That’s where the distillation step turns trash-grade oil into cash-grade fuel. The big question every plant manager wrestles with: do you go batch or continuous for your waste oil distillation system?

I’ve walked plenty of factory floors from Romania to the Philippines where owners lost sleep over this exact decision. Get it wrong and you’re stuck with either a clunky setup that can’t keep up or a high-maintenance beast that bleeds cash on repairs. Get it right, and you’re pumping out EN590-spec diesel at 300–500 liters an hour with almost no babysitting. Let’s cut through the noise and lay out exactly what matters.

Waste oil from pyrolysis isn’t one thing. Tire oil runs thick with aromatics and steel contaminants. Plastic oil carries more light ends and chlorine risks. Oil-sludge oil? Heavy as tar and full of water. Your feedstock decides half the battle.

Ask yourself three quick questions:

Real example: a 15-ton tire pyrolysis plant in Poland was making 6 tons of raw oil a day. They started with a 5 m³ batch tower. Worked okay for six months. Then oil demand spiked. Suddenly they were running the still 20 hours straight, burning burners overtime and still falling behind. Switched to a small continuous distillation line (10 m³/day capacity) and cut energy use 28 % while hitting 450 liters/hour of clean diesel. Same crew, happier boss.

Batch systems are the workhorses most plants start with, and honestly, a lot never leave them.

How it works in real life You pump your raw oil into a kettle—typically 5-30 m³. Fire it up to 120 °C to knock out water and lights, then push to 350-380 °C under vacuum. Diesel cuts come off between 180-360 °C. When the kettle runs dry of good fractions, you cool, drop bottoms, clean, repeat. Whole cycle: 12-18 hours.

Pros that actually matter on the ground

Numbers from a Turkish site running two 10 m³ batch towers: Raw oil in → 6,200 L/day Diesel out → 4,050 L/day (65 % yield) Power bill → ~$140/day Labor → two guys, 8-hour shifts Payback → 11 months at $0.75/L diesel

Biggest complaint? You’re always waiting on the next batch.

Once you’re consistently over 10-12 tons of raw oil a day, continuous starts making real sense.

How it actually runs Raw oil gets preheated, then flows nonstop through a pipe still or thin-film evaporator. Temperature climbs in stages. Light ends pop off first, diesel in the middle, heavy residue out the bottom. Pumps and valves keep everything moving 24/7.

What changes on the shop floor

A 30-ton pyrolysis plant in Spain went continuous two years ago. Before: three batch kettles, 14-hour cycles, 62 % diesel yield. After: one 20 m³/day continuous line, 69 % yield, labor down from six men to two, and they now sell diesel at truck stations instead of blending it off cheap.

Downsides people don’t talk about enough

| Factor | Batch System | Continuous System |

| Daily raw oil | 3–15 tons | 12–100+ tons |

| Typical diesel yield | 60–68 % | 65–72 % |

| Capital cost (10 t/day) | $80k–$150k | $280k–$450k |

| Power per ton oil | 90–120 kWh | 65–85 kWh |

| Labor | 2–4 people | 1–2 people |

| Maintenance downtime | Planned, 1–2 days/month | Unplanned stoppages hurt bad |

| Feed flexibility | Excellent | Needs consistent quality |

| Payback time | 8–14 months | 14–24 months |

More owners than you’d think run both. Batch tower for dirty or low-volume days, small continuous line for the steady stuff. Gives you flexibility without betting the farm.

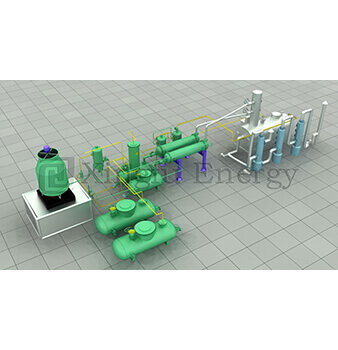

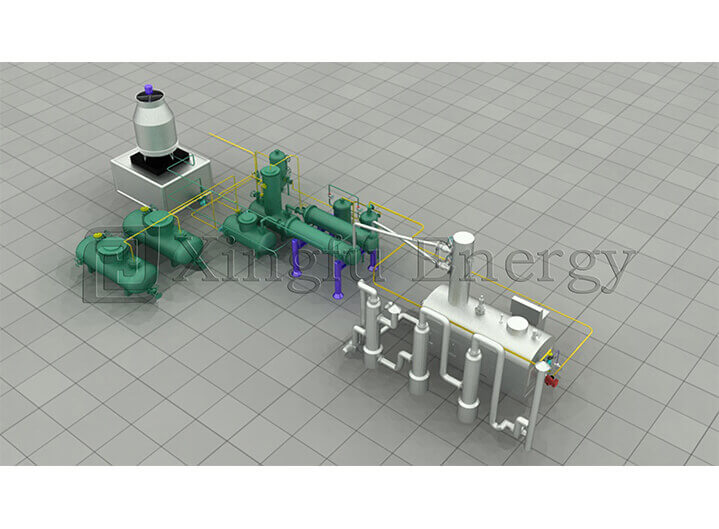

Before you lock in a decision, worth knowing who’s actually delivering these systems day in, day out. Qingdao Xingfu Energy out of Shandong has been cranking out waste oil distillation units alongside their pyrolysis plants since 2010. Same factory makes industrial boilers and pressure vessels, so the steel work and welding certifications are rock solid—CE, ASME, A-level boiler licenses, the works. They’ve shipped batch and continuous distillation skids to over 30 countries, from freezing Mongolia to humid Southeast Asia, and the feedback is usually the same: starts quick, runs steady, and their after-sales guys actually pick up the phone at 2 a.m. when the vacuum pump throws a fit.

There’s no universal “best” between batch and continuous waste oil distillation—it’s about matching the system to your real daily volume, feedstock consistency, and how clean you need the diesel to be. Under 10 tons of raw oil a day? Stick with batch, pocket the savings, and sleep easy. Pushing 15+ tons with stable supply? Continuous will pay you back in energy and labor for years. Most plants I’ve seen thrive when they size honestly, plan one step ahead, and don’t try to force a continuous line on a batch-sized operation. Do the math on your own numbers, talk to someone who’s run both, and you’ll make the call that keeps the oil flowing and the bank account growing.

Q: Can a batch waste oil distillation system hit EN590 diesel spec?

A: Yes, absolutely. With a good fractionation column, proper vacuum, and a small polishing step, plenty of 10 m³ batch units in Europe sell straight to gas stations.

Q: How much water in the raw oil breaks a continuous waste oil distillation unit?

A: Most continuous lines handle up to 5–8 % water fine. Over 10 % and you’ll fight emulsions and pressure swings. A simple pre-heater or settling tank fixes 90 % of those headaches.

Q: What’s the real energy difference between batch and continuous oil distillation?

A: Field numbers show continuous uses 65–85 kWh per ton of processed oil; batch runs 90–120 kWh. On a 15-ton/day plant that’s $15,000–25,000 saved yearly on the electric bill alone.

Q: How long does it take to switch a plant from batch to continuous distillation?

A: If piping and power are already close, a 10–20 ton/day continuous skid can be installed and running in 6–8 weeks. Budget 2–3 weeks extra for commissioning and tweaking cuts.

Q: Is continuous distillation worth it if my pyrolysis oil quality jumps around a lot?

A: Not usually. Continuous shines with steady feedstock. If your oil specs swing hard week to week, stick with batch or add good pre-treatment tanks first. Otherwise you’ll spend more time cleaning than distilling.