● Rotate pyrolysis reactor with anti coking design. No coking problem.

● Adopt multilevel cooling design, to get more fuel oil.

● Hot air heat, cooperated with low temperature pyrolysis catalyst, extend working life of plant.

● Enclosed production all the way, no leakage and no dust loss, environmental protection.

● Exhaust gas multistage processed, gas emission reach European Standard level.

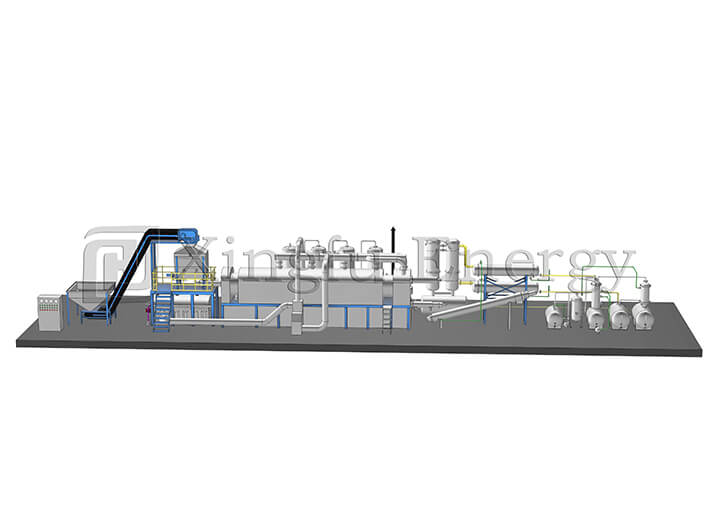

1.Technological Process

(1) Broken tyre transported to feeder firstly by conveyor, then to reactor.

(2) Oil and gas from pyrolysis go into gas-liquid separating tower and separate, and enter into condenser to liquify , to get fuel oil, then enter into oil storage tank.

(3) Coarse carbon black and steel wire from pyrolysis are output by automatic slag remover, transported to carbon black processing system by cooling hoist. Separate steel wire and carbon black through the magnetic separator,to get industrial carbon black and steel wire.

(4) Shatter carbon black, to get industrial carbon black after deeply processing. Steel wire compressed into a piece of scrap processing.

(5) Flammable gas enter into waste gas process tank to desulfur. Then extracted by vacuum pump, enter into water sealed tank and send to hot air furnace.

2.Main Performance Parameter

| Item | 30 T fully continuous waste tyre pyrolysis plant |

| Type | XFLJ–30 |

| Capacity | 30T/D |

| Operating temperature | ≤650° |

| Material | Q345R |

| Fuel consumption in start | 400 kg |

| Fuel consumption in operation | 0(the syn gas from the system be burnt by the system itself) |

| Heating way | Hot air circulation heating |

| Tire requirement | Tyre piece ≤20mm |

| Working pressure | Normal pressure |

| Methods of flame retardant | Nitrogen Blow |

| Total power | 190 kw |

| Running power | 190 kw/h |

| Boundary dimension | 14000mm(L) × 2400mm(W) ×4000mm(H) × 2 |

| Floor space | 36000 mm ×8000 mm |

| The highest install elevation | 7000 mm |

| Labor | 2-3 people |

| Working life | 10 years |

2.Product Recovery Rate

Fuel oil: 45-50%

Carbon residue: 32-36%

Steel wire: 2-14%%

Syn gas: 3-5%